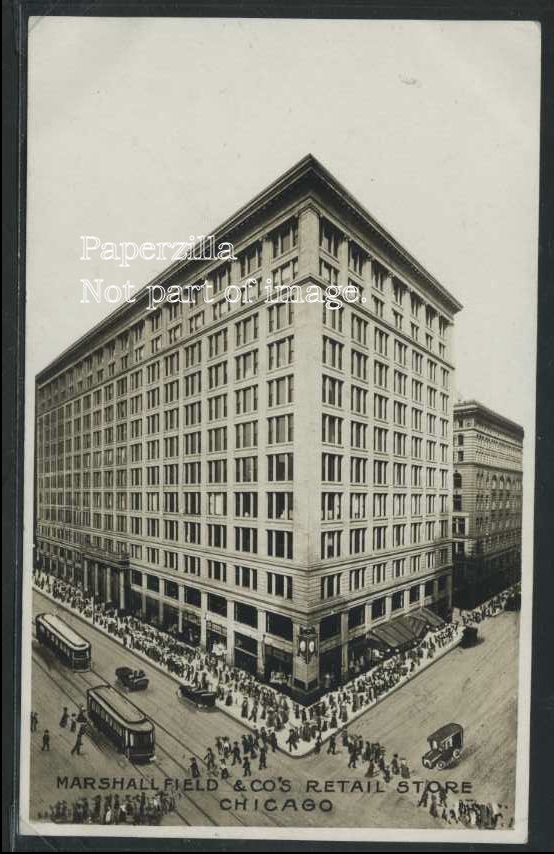

On a recent adventure I found a pair of bent billiards that had the Made in London England circle stamp on the right side of the shank and the Germanic script stamping, Royal Coachman on the left side of the shank. They were also stamped with a shape number 215. I did a bit of research to see if I could identify the maker. From the markings I was pretty confident that I was dealing with a Comoy’s seconds line but wanted to make certain I was right. The circle stamp on the right side of the shank was a giveaway to that identification. The shape number looked very familiar to me and the overall look said Comoys. So I looked in two the places that I always go to when beginning a hunt for info. The first is a website set up by Pipephil called Logos and Stampings. There I found that the Royal Coachman was indeed a Comoys brand. The site showed that the pipes were made by Chapuis-Comoys. The second site I looked at was Chris’ pipe pages http://pipepages.com/64com19s.htm . Chris has collected old catalogues and documents that give shape charts and many historical materials that cannot be found in other places. I have copied a page from the shape chart below and you can see that the 215 shape number matches not only the Comoys number but also the shape.

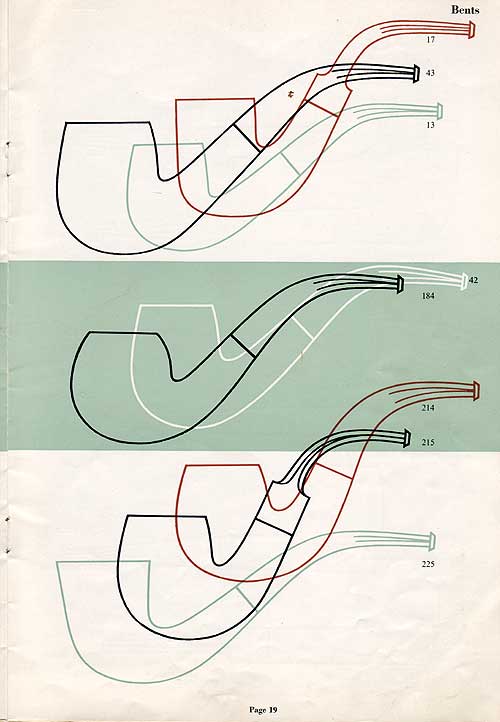

When I brought the pipes home from the antique shop they looked like the photos below. There were actually in pretty good shape for their age. The dealer said that he bought these along with 20 other pipes from a widow who was selling off her late husband’s estate. He had some interesting old pipes and I was able to pick through them and brought six of them home with me. These are the first pair of the bunch. The bowls were lightly smoked with a bare minimum of cake. The top pipe in the picture below was less smoked than the bottom one. Both pipes were grimy on the outside of the bowl and had some oxidation on the stems. There were no tooth marks on the top pipe and only a little tooth chatter on the underside of the bottom pipe. The top pipe has three small fills that are visible in the first photo below and a slight nick in the shank on the right side near the stem. The second pipe has a few fills as well with the largest of them visible low on the left side of the bowl in the photo below. The rims on both were clean and undamaged and showed no tar build up. On the right side of the bowl of both pipes there was a small spot of white paint.

I reamed the bowls with a PipNet reamer to remove the slight cake build up and clean out the bowl. I wiped down the exterior of the bowl with Murphy’s Oil Soap to remove the grime and grease build up. It also took off the paint spots on the right side of the bowl. I use the soap undiluted as I find it does not remove the finish on the bowl as much as when it is diluted with water. I rubbed it on and scrubbed it with cotton pads and wiped it off with the same pads.

I cleaned out the inside of the shank on both pipe using cotton swabs and isopropyl alcohol. Both had a slight reservoir in the shank with the drilling being quite high in the shank to accommodate the bend in the shank to bowl junction. I cleaned out the airway with pipe cleaners and then the inside of the bowl with folded pipe cleaners and cotton swabs.

I wiped down the stems with isopropyl alcohol on a cotton pad and then cleaned out the inside with pipe cleaners. The opening/airway on the end of the tenon was very small so I had to work to push the pipe cleaner into place. I had not seen an airway this constricted in a long time. The draw on the pipe was very tight; it was like pulling air through a coffee stirrer. When I pulled the pipe cleaner out a small ring came out with it. It is visible in the photo of the pipe cleaner below. The stem on the left is the one that the ring came out of and the stem on the right still has the ring. It appears to be made of brass and is a thin ring that constricts the airway for about 1/16th of an inch. With the ring removed the draw was very open. I continued to clean out the stem and airway until it was spotless and the pipe cleaners came out clean. I cleaned the end of the tenon with cotton swabs and isopropyl alcohol.

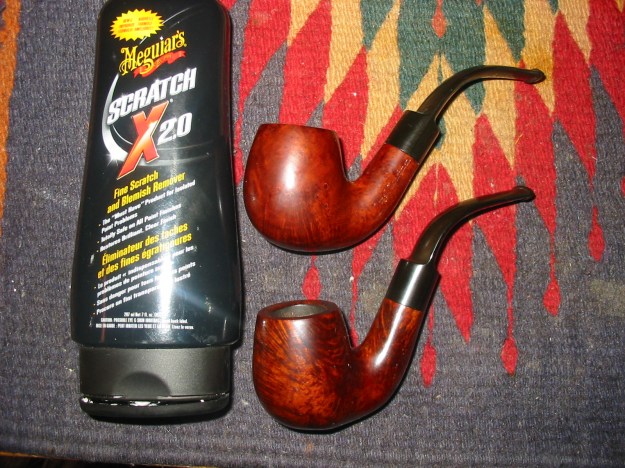

I then used some Meguiar’s Scratch X2.0 on the stems to scrub the scratches and polish the stems. I applied it with a cotton pad and scrubbed and rubbed it off. The photos below show the stems after the polishing. There was some deep seated oxidation that came to the surface of the stems. There was more oxidation on the top of the stems than on the underside.

I buffed the stems with red Tripoli on my buffer to remove more of the oxidation. I followed that up with White Diamond polish on the buffer as well. I also buffed the bowl with White Diamond. The shine really came out.

There was still oxidation that came up on the stems. I sanded it with a medium and a fine grit sanding sponge and then wet sanded with 400 and 600 grit sandpaper. This removed the remaining oxidation in the stem. I then wet sanded them with 1500-2400 grit pads. I dry sanded them with 3200-12,000 grit pads. I rubbed the stems down with Obsidian Oil and when it had dried I buffed them with White Diamond and then gave both the bowls and stems multiple coats of carnauba wax and buffed them with a soft flannel buff on the buffer. The finished pipes are shown below. They are ready to enter the next phase of their lives.