I seem to have been doing quite a few bowl topping job here recently. I decided to document the process a bit and focus on the rim work to make the work more clear so others can give it a try. I have chosen two different Comoy’s pipes and an Orlik billiard that I recently reworked. Each one had serious rim damage that needed topping to effectively repair them. The first one shown below was a Comoy’s London Pride that I have written about in full earlier. This one had both inner and outer rim edge damage. The top had become rounded on both edges and it was poorly done. I researched what it was supposed to look like and topped it accordingly. The second one was an Orlik billiard that had a different type of damage – burn marks and gouges that only a topping would repair. The third one was the Comoy’s St. James pipe that repaired.

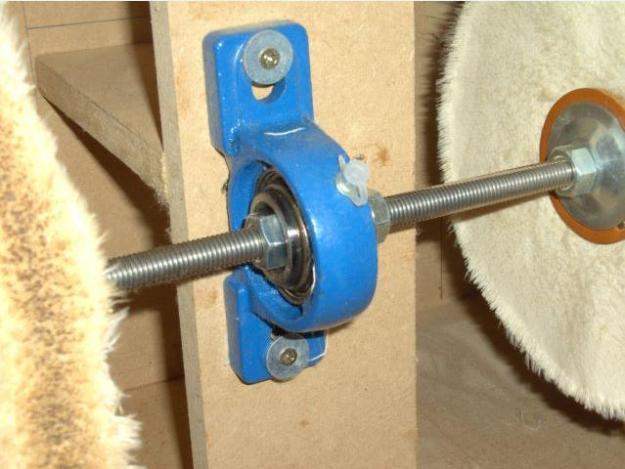

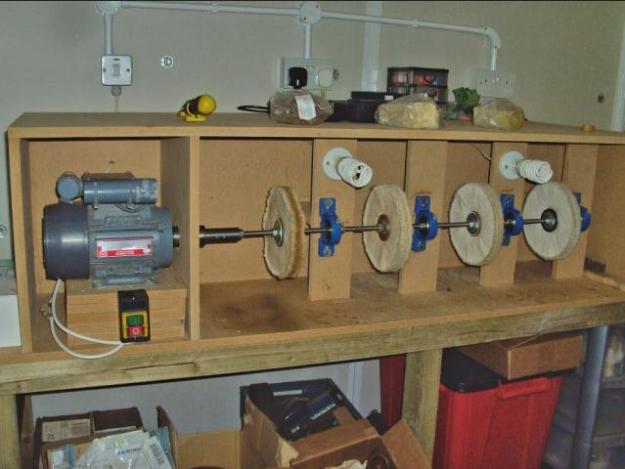

All of my bowl topping starts the same way. I have a flat board that I spread a piece of sandpaper on and place the bowl flat against the board on the sandpaper. As I work it against the paper I am careful to keep the bowl top flat against the paper and not lift an edge or angle the bowl. It is very easy to seriously change the profile of the bowl. I also constantly check to ensure that I only remove enough of the damaged briar to repair the problem and not take too much off.

The next series of photos show the progress of the topping. On the Comoy’s St. James I took photos each time I checked on the progress of the topping so you can see the point at which I stopped the sanding. The other two bowls I show the end product of the topping.

On each of the bowls that I top I also use a folded piece of sandpaper to smooth the inner edge of the rim. This has to be done carefully or the bowl can easily go out of round. On the Comoy’s London Pride I used the folded sandpaper to create a slight bevel on the inner edge of the rim to match what was originally on that pipe. On the St. James and the Orlik I merely sanded the edge to make a clean and smooth surface.

Once the rim is successfully topped the process truly has only begun. The surface then needs to be sanded with higher grits of sandpaper and micromesh sanding pads to remove scratches and give a smooth out the briar so that when it is stained the surface does not show scratching or repair damage. Then it has to be stained in such a way that the colour blends in with the colour of the bowl. When I am refinishing a pipe I find that the simplest and most straight forward way to guarantee a match it is to remove the previous finish as much as possible and start from scratch with the whole bowl. This is not always possible and often the matching process takes several stains and several coats to get a good blend with the rest of the bowl. It is often a matter of darkening a stain or thinning it with alcohol to lighten it or even blending several colours of stain together to get the mix that actually blends in seamlessly to the bowl colour. This part is probably the most time consuming part of the process.

The first two photos below show the stain on the Comoy’s London Pride and how the bowl and rim match – both before and after buffing and waxing. The third photo shows the Orlik after staining and buffing. There is still a slight bit of rim darkening on this rim that I left on purpose. The fourth and fifth photos show the St. James after staining and then after buffing and waxing. The change in the shape or height of the bowl is negligible and the overall improvement to the profile and look of the pipe is well worth the effort.

I continue to learn and experiment with the process of topping and sanding a bowl to repair the damage inflicted by the previous owner – whether it is thoughtless carelessness or accidental damage. Each time I do the work I become more confident in the process and pleased with the results. If you don’t try and practice you will never learn. If you have comments to add about the process or have suggestions of improvements I encourage you to record them, photograph them and share them with us all. The community benefits from the combined knowledge of its members. Thanks for reading this blog post.