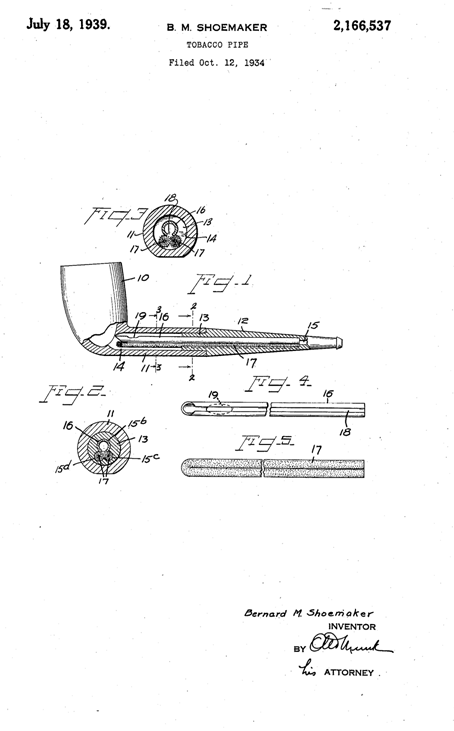

In one of the lots of pipes I picked up on Ebay this threaded bowl was present. There was not a pipe base that it fit even though there were two threaded bases in the lot. One was a WDC Bakelite base that was wider and had different threads and the other was a no name older base also with a wider base and different threads on the bowl. I have not seen a bowl with this kind of set up before. The bowl itself is a tube of briar fit over an aluminum bottom. The bottom of the bowl is threaded on the end that screws into the pipe and the upper portion is inserted into the bowl. The top of the insert is a cup that extends a third of the way up the sides of the bowl. I have quite a few metal pipe bases and older Bakelite bases available here but this bowl does not fit any of them. It is truly a mystery to me.

When I got it the finish was worn and there was a crack in the bottom edge of the bowl where it sits against the aluminum. The crack went up about a quarter of the way up the outside of the bowl. The bottom of the threaded portion is stamped PATENT APD FOR, which I assume is the abbreviation of Patent Applied For. I have no idea about country of origin or manufacturer so checking for patent information is difficult. If anyone has seen one of these and has some information please let me know.

Since I am working with the bottom of my refurbishing box, I decided to clean up the bowl and restore it so that when I find a base that it fits it will be ready. The rim was rough so I topped the bowl with a piece of 220 grit sandpaper on a flat surface. I twisted the bowl into the sandpaper to remove the damage to the surface.

I reamed the bowl with a PipNet reamer to clean up the inside. The outer edge of the bowl rim was damaged so I sanded it until it was smooth. I also used a piece of folded sandpaper to smooth out the damage to the inner rim. I scrubbed the aluminum base with acetone on cotton swabs to clean out the grooves/threads on the nub. I scrubbed the base on the outside and the inside of the bowl. I picked the threads with a dental pick to clean out the buildup of tars in each groove. I wiped down the exterior of the bowl with the acetone to remove the finish.

I sanded the bowl with 220 grit sandpaper and also with a medium grit sanding sponge. I sanded it with 1500-1800 grit micromesh sanding pads. Once the surface was smooth I cleaned out the crack with a dental pick and filled it with superglue and briar dust. I sanded that area until it was smooth and blended in with the rest of the bowl. I wiped it down a final time with the alcohol soaked pads to remove the dust before I gave it the first coat of the two step stain.

I stained it with a black aniline stain, flamed it and then restained and reflamed it again. Once the stain was set I wiped it down with Everclear on a cotton pad to remove the top coat of black. My intention was to set the black into the interesting grain pattern around the bowl and rim and then remove the excess before giving a second colour of stain as a top coat.

I buffed the bowl with red Tripoli to finish removing the excess black and to also smooth out any existing scratches in the bowl. I sanded it with a fine grit sanding sponge and then with 1500 grit micromesh sanding pads. The next three photos show the bowl before I gave it the top coat of stain.

For the second coat of stain I used an oxblood aniline stain. I applied it and flamed it and then buffed it to give it a shine.

To finish the bowl I buffed it with White Diamond on the wheel and then gave it multiple coats of carnauba wax to protect and polish it. The finished bowl is seen in the photos below. It is ready for the mystery base that will allow it to once again be filled with tobacco and smoked.

Once again, I would appreciate any information that folks may have regarding potential makers for the bowl and potential bases that would hold this kind of threaded bowl. For information sake: it does not fit the Pacemaker, the Falcon, Alco, Viking or any of those pipes. It also does not fit the WDC bases or older Bakelite bases that I have tried. Thanks ahead of time for your help.