by Steve Laug

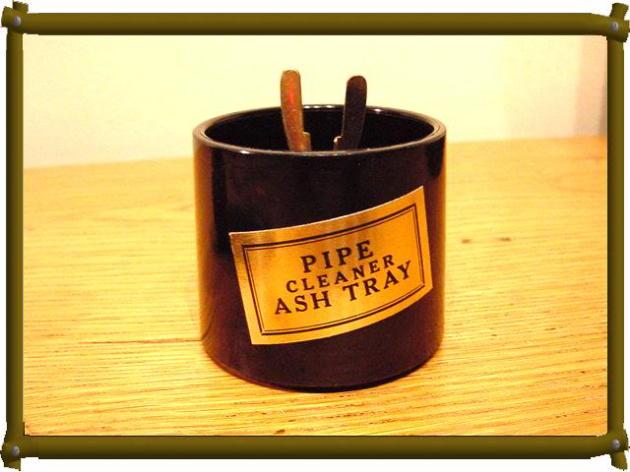

One of the side hobbies that comes with being a pipe smoker and pipe accumulator is the collecting of pipe smoking ephemera. I am always looking for old pieces that go along with pipes whether they be Bakelite pieces such as Wunup Baccyflaps, ash trays or tobacco jars or other interesting pieces of pipe paraphernalia. Something about these old pieces brings to mind quieter times. It makes me wonder if I am just an old soul born in a wrong era! Ah well, I continue to pick up interesting pieces along the way and enjoy having them in my pipe cupboard in my office. The one that I wish to show you all today is a great little piece – a Pipe Cleaner Ash Tray made out of Bakelite.

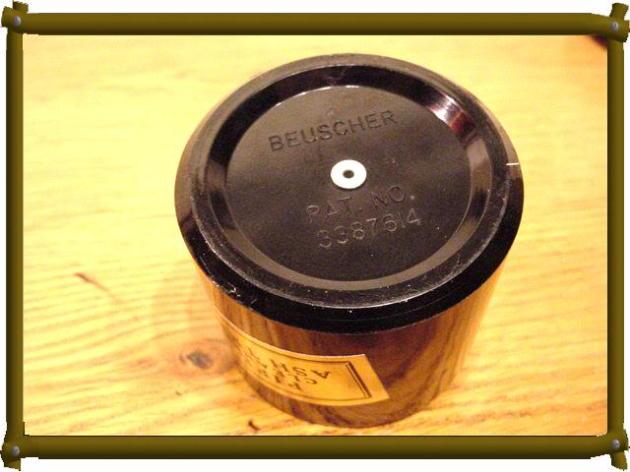

On the bottom of the ashtray there was a patent number cast in the Bakelite. I used that number to research the patent information on this interesting piece of ephemera. One of the beauties of the internet is that you can quickly do a patent search of the United States Patent Office Database. This website is your entry to a world of historical information on some of the pieces that you may have in your pipe cabinet or on your desk. http://www.uspto.gov/patents/process/search/ Once you are on the site you can search for information either by patent number or by the company name that is on the product. Quite quickly you are taken to a Quicktime picture of the patent information. It is there for you to read on line or you can copy it and save it for later reference.

In this case there was indeed a patent taken on the piece by W.B. Beuscher. The patent information included drawing of the invention and also a great verbal description of the piece. I have included them below because they are fascinating information to have at hand for these old pieces. I have used that US Patent Office database for a lot of different patent information from pipes to reamers and always am intrigued by the inventiveness of pipe smokers who are on the hunt for the best tools of the craft for cleaning and smoking their pipes! Have a look at the drawings and the description of this 1966 item.

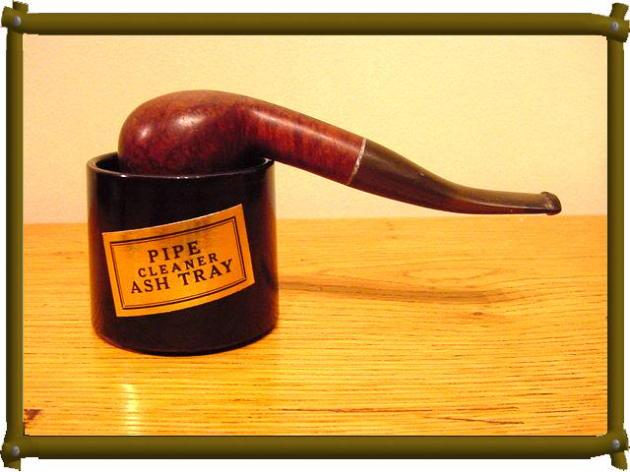

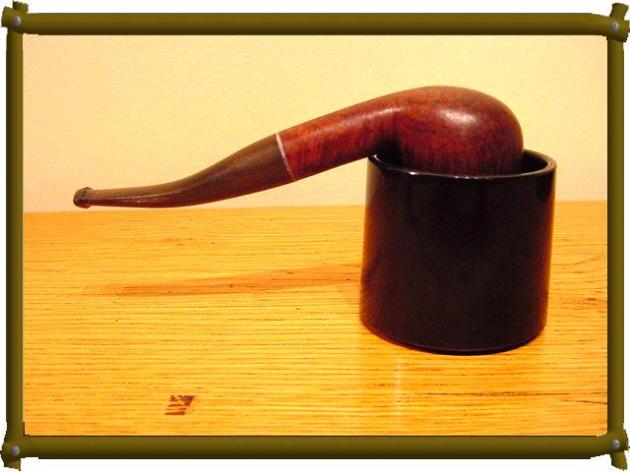

The particular piece that I have is a Beushcer and it is about the size of a coffee or tea mug. It is different from the drawing above only in terms of the ash tray itself. In mine it is a cup and anchored to the bottom of the cup are the patented pair of blades that can be squeezed to adjust to the width of a pipe bowl. The picture below shows the inside of the bowl and the blades a bit more clearly so that you can see the details.

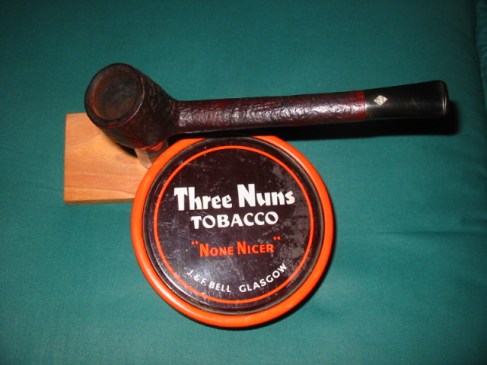

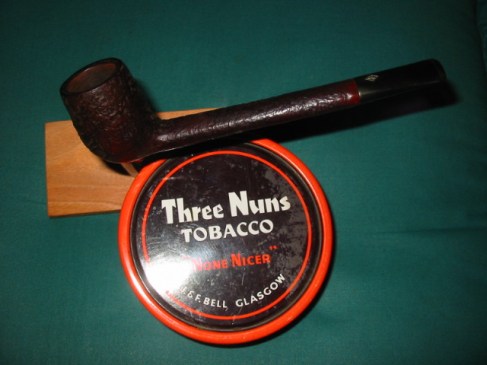

The next series of photos show the ash tray with a pipe that has been fit on the blades. The basic concept of the gadget is that after smoking a bowl of tobacco you turn your pipe over on top of the blades and give it a twist or two and the dottle and remainder of your tobacco is quickly removed into the ash tray for easy disposal. Then is a folded pipe cleaner is used to give the bowl a quick swab, another is run through the shank and stem and you are ready to reload your pipe for another enjoyable bowl in a clean pipe.

The inventiveness and creativity seen in these gadgets never ceases to amaze me. I don’t think I will ever use this one but it is a great piece of pipe history to have around. The patent data gives a intimate glimpse into the mind of its creator. It gives me the ability to see what the basic idea was and what the inventor hoped to achieve with his invention.