Blog by Bryan

Bryan, SenatorXMG, on Smokers Forums posted this photo essay on a repair he did on a cracked shank on a Peterson Mark Twain that he purchased. I asked for permission to post it here for information and passing on a great trick to others who would choose to use his method. He gladly granted that permission and I include it below for your use.

Well…today was the day to fix my Peterson Mark Twain with the cracked shank. I had previously posted on Smokers Forums regarding the problem and looking for advice on repairing it. I include the text and picture that I posted below.

I bought a Peterson Mark Twain off of eBay and when it arrived I discovered there was a crack in the shank. With the silver cap on the shank it was not easy to see and I believe the seller that he was unaware. You can only see the crack from inside the shank…with stem in place, it’s evident that it expands a little as the stem sits more deeply in the shank and is not quite so secure. Other than this crack, the pipe is in pretty good condition. The seller offered either a full refund or a partial one of $55 (he increased from the original $40 he offered). If I could have this adequately fixed, I’d be interested in that.

I’ve included a picture of where in the shank the crack is. It actually runs from the top of the shank down to the air hole.

I’m wondering if this is something I could repair myself. Any repairmen out there who could give me a basic step by step idea of how I would approach this fix? I was considering the following:

– remove cap (this is fairly straight forward. I’ve done this before)

– add appropriately-sized shank ring. Might have to sand down an area so that the ring is flush with the remaining shank? (I have no idea how this part is done and how I’d get a tight fit of the shank ring).

– re-install cap (easy to do)

While I’m pretty handy, this seems like it could be a job for someone with skills greater than mine. Would the $55 the seller has offered me back cover this type of repair from someone with experience?

Crack location marked in red/black indicated on silver cap (actual location is seen on the inside)

I decided to repair the pipe myself and created a small photo essay on the work done in repairing the pipe. Here it is:

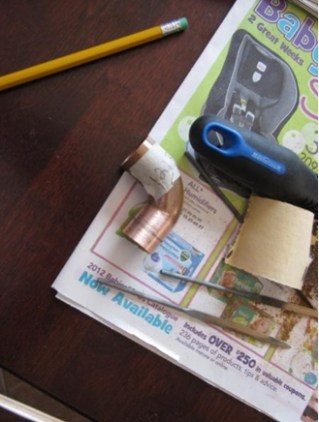

The silver cap was removed with use of heat. Once it is removed the crack is very visible. Copper piping will act as source of repair band.

I sanded down repair area where copper band will be installed.

The copper piping is marked and ready to be cut.

Copper band cut and filed smooth:

Heat for installation. No blow-torch to heat…had to use my propane space heater (it worked!):

Cooper band installed…with a little bit of gentle force:

To the grinder to clean it up a little:

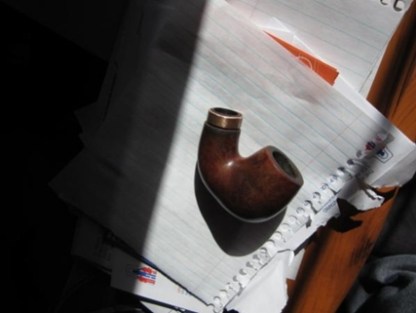

Ahhhh…that’s a little better:

All finished!! Silver cap re-installed. With the installation of the repair band, the crack is much tighter and the stem now sits much more nicely!!

All in all…wasn’t a terribly difficult repair. The hardest part was determining how much to sand down the area where the band would go. But, it all worked out fine!

Bryan