by Steve Laug

The next pipe I have chosen is aa classic Danish style freehand with a smooth rim and a plateau shank end. The pipe has a mixed finish of sandblast and smooth finishes. The bowl has a sandblast patch on the left side of the bowl and the rest is smooth other than the shank end. We purchased it from the seller on 06/05/2021 in Chicago, Illinois, USA. The contrast of the brown stains on this pipe makes the smooth grain and depths of the sandblast stand out. The dark stained sandblast on the sides of the bowl worked well with the stain on smooth portions. The pipe is stamped around Viggo [arched over] Nielsen high on the left side of the shank. Under that toward the bottom left side is stamped Hand [over] Finished. On the right side of the shank it is stamped Made in Denmark. The bowl had been reamed recently but there was light lava on the rim top and chipping damage on the inner edge. The plateau on the shank end was dusty and soiled. The black vulcanite saddle stem was heavily oxidized, calcified and had tooth chatter and marks on both sides of the stem ahead of the button edge. There was no stamping on the top or sides of the stem. Jeff took photos of the pipe before his cleanup work. They tell the story and give a glimpse of the pipe.

Jeff took close up photos of the bowl and rim to capture the condition of the pipe before he started his cleanup work. The bowl walls are clean in the photo showing that they have been reamed recently. The lava on the rim top and on the edges and the damage to the inner edge are visible. The next photos show the stem surface. There is oxidation, calcification and tooth marks and chatter on both sides near the button and wear on the button surface and edges.

Jeff took close up photos of the bowl and rim to capture the condition of the pipe before he started his cleanup work. The bowl walls are clean in the photo showing that they have been reamed recently. The lava on the rim top and on the edges and the damage to the inner edge are visible. The next photos show the stem surface. There is oxidation, calcification and tooth marks and chatter on both sides near the button and wear on the button surface and edges.

He also took a photo of the bottom of the bowl and shank to show the beautiful grain around the bowl and shank sides and the sandblast patch on the left side. It is very dirty but this is another beautiful pipe.

He also took a photo of the bottom of the bowl and shank to show the beautiful grain around the bowl and shank sides and the sandblast patch on the left side. It is very dirty but this is another beautiful pipe.

He took photos of the stamping on the sides of the shank. It is clear and readable as noted above.

He took photos of the stamping on the sides of the shank. It is clear and readable as noted above.

I turned to Pipedia to learn about Viggo Nielsen. I had memory about him being somehow connected to Kai Nielsen but I was not sure of the relationship of the two. In Pipedia I learned

I turned to Pipedia to learn about Viggo Nielsen. I had memory about him being somehow connected to Kai Nielsen but I was not sure of the relationship of the two. In Pipedia I learned  that Viggo, now deceased, was born in 1927. I believe that during World War II he worked for Stanwell making pipes out of birch due to a shortage of briar. In 1948 he opened the Bari pipe factory and in 1951 began to make briar pipes. He carved both classic and freehand pipes.

that Viggo, now deceased, was born in 1927. I believe that during World War II he worked for Stanwell making pipes out of birch due to a shortage of briar. In 1948 he opened the Bari pipe factory and in 1951 began to make briar pipes. He carved both classic and freehand pipes.

In 1978 Bari was sold to a company in Germany and he and his two sons, Jorgen and Kai started making Faaborg pipes. Now I knew the connection between the two names that I remembered. https://pipedia.org/wiki/Nielsen,_Viggo

I turned to address the pipe itself. Jeff cleaned up the pipe for me. He reamed the bowl with a PipNet pipe reamer and cleaned it up with a Savinelli Fitsall Pipe Knife. He scrubbed the exterior with Murphy’s Oil Soap and a tooth brush to clean off the grime off the finish and the overflow of lava on the rim top. There was still damage on the inner edge of the rim and some burn marks. He cleaned up the internals of the shank, mortise and stem with pipe cleaners, cotton swabs and alcohol to remove all of the oils and tars in the pipe. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and was able to remove much of the oxidation. When it arrived here in Vancouver it was a clean pipe and I knew what I had to work with. I took photos of it before I started my part of the restoration.

I took photos of the rim top and the stem to show their condition once it arrived in Canada. Jeff was able to clean up the inside of the bowl and lava overflow that was shown in the rim and inner edge of the bowl in the photos above. He was also able to get rid of the grime and grit in the surface of the briar. The rim top and edges looked better but there was still some damage. The stem also looked better. The oxidation and calcification was gone and the tooth marks were obvious on both sides.

I took photos of the rim top and the stem to show their condition once it arrived in Canada. Jeff was able to clean up the inside of the bowl and lava overflow that was shown in the rim and inner edge of the bowl in the photos above. He was also able to get rid of the grime and grit in the surface of the briar. The rim top and edges looked better but there was still some damage. The stem also looked better. The oxidation and calcification was gone and the tooth marks were obvious on both sides. I took photos to try and capture the stamping on the shank sided. It was clear and readable as noted above. I removed the stem and took a photo of the pipe sans stem to show the proportions of this unique beauty.

I took photos to try and capture the stamping on the shank sided. It was clear and readable as noted above. I removed the stem and took a photo of the pipe sans stem to show the proportions of this unique beauty.

I decided to start with addressing the damage on the top and inner edge of the rim. I used a folded piece of 220 grit sandpaper to begin. I followed that up with a half sphere and a piece of 220 sandpaper to clean up the damage on both and round out the bowl edge and remove the damage.

I decided to start with addressing the damage on the top and inner edge of the rim. I used a folded piece of 220 grit sandpaper to begin. I followed that up with a half sphere and a piece of 220 sandpaper to clean up the damage on both and round out the bowl edge and remove the damage.

I sanded the smooth portions of the briar with 320-3500 grit 2 x 2 inch sanding pads. I wiped it down with a damp cloth after each sanding pad. It began to look very good.

I sanded the smooth portions of the briar with 320-3500 grit 2 x 2 inch sanding pads. I wiped it down with a damp cloth after each sanding pad. It began to look very good.

I polished the smooth briar with micromesh sanding pads. I dry sanded it with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth. The bowl began to take on a rich shine and grain was beginning to stand out.

I polished the smooth briar with micromesh sanding pads. I dry sanded it with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth. The bowl began to take on a rich shine and grain was beginning to stand out.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it into the smooth part of the finish with my fingers to get it into the briar. I used a horsehair shoe brush to work it into the sandblast part of the finish. After it sat for a little while I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it into the smooth part of the finish with my fingers to get it into the briar. I used a horsehair shoe brush to work it into the sandblast part of the finish. After it sat for a little while I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration.

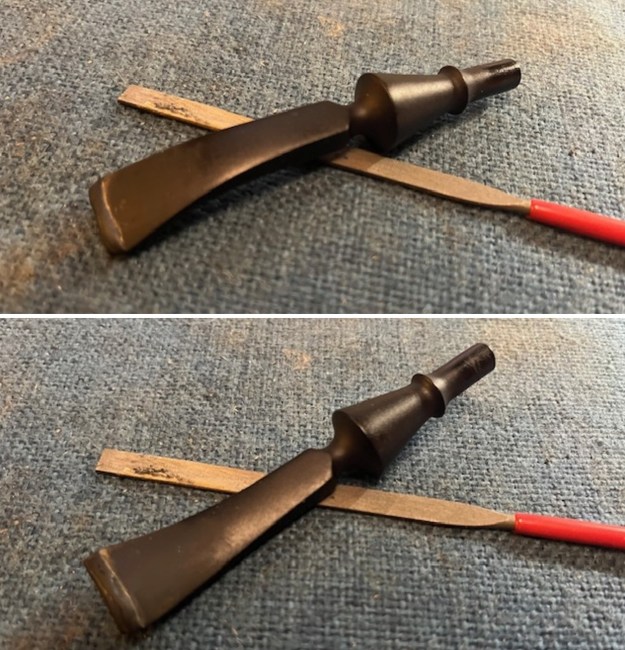

I set the bowl aside and worked on the stem at this point in the process. The deep tooth marks on both sides were too deep for heat to work on. I filled them in with some Black rubberized CA glue. Once it cured I used the file to flatten the repair and sanded it with a piece of 220 grit sandpaper.

I set the bowl aside and worked on the stem at this point in the process. The deep tooth marks on both sides were too deep for heat to work on. I filled them in with some Black rubberized CA glue. Once it cured I used the file to flatten the repair and sanded it with a piece of 220 grit sandpaper.

I sanded the stem further with 320-3500 grit 2 x 2 inch sanding pads. I wiped the stem down after each pad with some Obsidian Oil. It began to take on a rich look.

I sanded the stem further with 320-3500 grit 2 x 2 inch sanding pads. I wiped the stem down after each pad with some Obsidian Oil. It began to take on a rich look.  I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a damp cloth to remove the sanding dust. I used the Before & After Pipe Polish to remove the small minute scratches left in the vulcanite even after the micromesh regimen. I finished by wiping the stem down with a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a damp cloth to remove the sanding dust. I used the Before & After Pipe Polish to remove the small minute scratches left in the vulcanite even after the micromesh regimen. I finished by wiping the stem down with a final coat of Obsidian Oil and set it aside to dry.

I put the stem back on the Viggo Nielsen Hand Finished Freehand and took the pipe to the buffer. I carefully buffed the bowl and stem with Blue Diamond to polish the briar and the vulcanite. Blue Diamond does a great job on the smaller scratches that remain in both. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up really nicely with a great contrasting stain look to the briar. The finished pipe is shown in the photos below. This is a unique Viggo Nielsen Hand Finished Freehand – the turned saddle stem gives the pipe a great look. The polished and repaired black vulcanite stem looks really good with the reds and browns of the finish. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches w x 1 ¾ inches l, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.69 ounces/49 grams. This is another pipe that I will be putting it on the rebornpipes online store in the Danish Pipe Makers Section shortly, if you are interested in adding it to your collection. Thanks for walking through the restoration with me on this beauty!

I put the stem back on the Viggo Nielsen Hand Finished Freehand and took the pipe to the buffer. I carefully buffed the bowl and stem with Blue Diamond to polish the briar and the vulcanite. Blue Diamond does a great job on the smaller scratches that remain in both. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up really nicely with a great contrasting stain look to the briar. The finished pipe is shown in the photos below. This is a unique Viggo Nielsen Hand Finished Freehand – the turned saddle stem gives the pipe a great look. The polished and repaired black vulcanite stem looks really good with the reds and browns of the finish. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches w x 1 ¾ inches l, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.69 ounces/49 grams. This is another pipe that I will be putting it on the rebornpipes online store in the Danish Pipe Makers Section shortly, if you are interested in adding it to your collection. Thanks for walking through the restoration with me on this beauty!