Blog by Steve Laug

Early in December I received and email from a reader of the blog about one of his first pipes. Here is what he wrote to me:

I have got a custom made briar tobacco pipe that split at the shank when I removed the pipe stem. It’s a hair line crack. Was looking to get an estimate of a repair. Was reading one of your repair articles of putting a brass ring to reinforce shank and stem connection. This is something I would like possibly have done. And what is the lead time for such a repair?… Thanks, Jake

The story behind this being his first pipe caught my attention. I forgot to ask him what the brand was. He sent me some photos of the crack in the shank but I changed out my computer and do not have access to those photos any longer. I figured that it would be a straightforward repair so I answered him and he shipped the pipe to me. This afternoon while I was working the package arrived from Jake. I opened it after work and took some photos of the pipe.

I wrote Jake an email to let him know that the pipe had arrived and asked him about the maker and the brand. He wrote me back and I am including that below.

I wrote Jake an email to let him know that the pipe had arrived and asked him about the maker and the brand. He wrote me back and I am including that below.

Hi Steve! I was actually going to contact you today to see if it did, but that’s good. Glad it finally made it to you. I bought that pipe back in 2015 from an Etsy retailer that went by the name of Salstrom & Skinner. I believe they are out of Oregon. They aren’t in business anymore from what I can tell, their online Etsy shop is no longer up. And yes, that is the stem that came with the pipe. –Jake

I thanked Jake and sent him my assessment of the pipe and what needed to be done to make a repair work on the pipe. I broke my assessment down to cover the bowl and shank issues and then the stem issues. Both contributed to the crack on the underside of the shank. I include a summary of the email that I sent to him below.

The damaged shank…

- I cleaned out the shank to check the crack and it goes all the way through.. Fortunately it is not too long maybe 1/4-1/2 inch into the shank.

- The shank was quite thin walled so I decided to glue it and then band it. I would open the crack and fill it with clear CA glue and clamp it shut until the glue dried.

- I would fit a thin brass band on the shank end and customize the fit. Once the fit was correct I would need to press it on the shank glue it in place. That would take care of the shank damage.

The stem issues…

- The stem is really a mess. The tenon was quite large and poorly cut. It still had the castings on it and the Made in Italy castings. These made the fit in the shank very tight and also I believe caused the crack originally as the shank is quite thin.

- I would need to smooth out damage on the tenon and remove the castings.

- I also would funnel the entry of the airway in the end of the tenon to make the draw better.

- The saddle portion of the stem was very rough and not round. There were file marks and cuts all around it and it did not fit against the shank well. The diameter of the stem and the shank did not match. I would need to round the saddle and removed the cuts and the file marks.

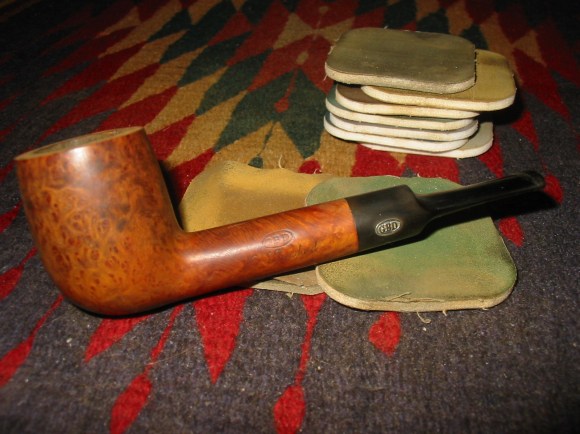

I took photos of the rim top and stem to show the general condition of the pipe. The bowl looked to be in good condition. There was some darkening and lava build up on the top back of the rim. I also took photos of the stem to show the cut marks and fill marks on the surface of the saddle.  I took some photos of the rough looking finish on the stem, its fit to the shank and the crack in underside of the shank.

I took some photos of the rough looking finish on the stem, its fit to the shank and the crack in underside of the shank. I removed the stem and took a photo of the pipe to have a look at the parts and overall look. I am still amazed by the thickness of the tenon.

I removed the stem and took a photo of the pipe to have a look at the parts and overall look. I am still amazed by the thickness of the tenon.  I took a photo of the castings on the tenon and on the airway entering the tenon end. It made the castings very clear.

I took a photo of the castings on the tenon and on the airway entering the tenon end. It made the castings very clear.  I started my work on the pipe by addressing the crack in the shank. I put the stem on the shank and opened it up. I filled in the crack with clear super glue (CA). I removed the stem and clamped the repaired shank together until the glue cured.

I started my work on the pipe by addressing the crack in the shank. I put the stem on the shank and opened it up. I filled in the crack with clear super glue (CA). I removed the stem and clamped the repaired shank together until the glue cured.  Once the glue had cured and the crack was bound together I fit a brass band on the shank end. After I had fit the band to the shank I removed it and coated the shank end and inside of the band with all-purpose glue. I pressed it onto the end of the shank. I set it aside and let the glue cure.

Once the glue had cured and the crack was bound together I fit a brass band on the shank end. After I had fit the band to the shank I removed it and coated the shank end and inside of the band with all-purpose glue. I pressed it onto the end of the shank. I set it aside and let the glue cure.  I took photos of the band on the shank from the various angles to show what it looked like. It is a pretty addition.

I took photos of the band on the shank from the various angles to show what it looked like. It is a pretty addition.

I set aside the repaired bowl and turned my attention to the stem. I used the blade of pen knife to funnel the airway in the tenon.

I set aside the repaired bowl and turned my attention to the stem. I used the blade of pen knife to funnel the airway in the tenon. I smoothed out the castings on the tenon with 220 grit sandpaper. I also smoothed out the file marks on the saddle portion of the stem and worked to make it round again.

I smoothed out the castings on the tenon with 220 grit sandpaper. I also smoothed out the file marks on the saddle portion of the stem and worked to make it round again. I put the repaired and newly shaped stem on the shank of the bowl and took photos of the look of the pipe. I still needed to polish it but the stem looked much better.

I put the repaired and newly shaped stem on the shank of the bowl and took photos of the look of the pipe. I still needed to polish it but the stem looked much better.

It was time to polish the stem now. I polished it with 1500-12000 grit micromesh sanding pads. I wiped the stem down with Obsidian Oil after each pad. I finished polishing it with Before & After Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil to protect the stem surface from oxidizing.

It was time to polish the stem now. I polished it with 1500-12000 grit micromesh sanding pads. I wiped the stem down with Obsidian Oil after each pad. I finished polishing it with Before & After Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil to protect the stem surface from oxidizing.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I am excited to finish this Salstrom & Skinner Handmade Acorn. It was a rustic pipe with a lot of flaws in craftsmanship of the briar and the stem but it is looking much better. The band on the shank and the reworked stem give the pipe a sense of newly formed class and character. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the polished brass band and the black vulcanite stem was beautiful. This smooth Handmade Acorn is good looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 48grams/1.69oz. It is a nice looking pipe and one that I will be sending back to Jake in the next few days. I look forward to hearing what he thinks of his “resurrected first pipe”. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

I am excited to finish this Salstrom & Skinner Handmade Acorn. It was a rustic pipe with a lot of flaws in craftsmanship of the briar and the stem but it is looking much better. The band on the shank and the reworked stem give the pipe a sense of newly formed class and character. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the polished brass band and the black vulcanite stem was beautiful. This smooth Handmade Acorn is good looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 48grams/1.69oz. It is a nice looking pipe and one that I will be sending back to Jake in the next few days. I look forward to hearing what he thinks of his “resurrected first pipe”. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.