Blog by Steve Laug

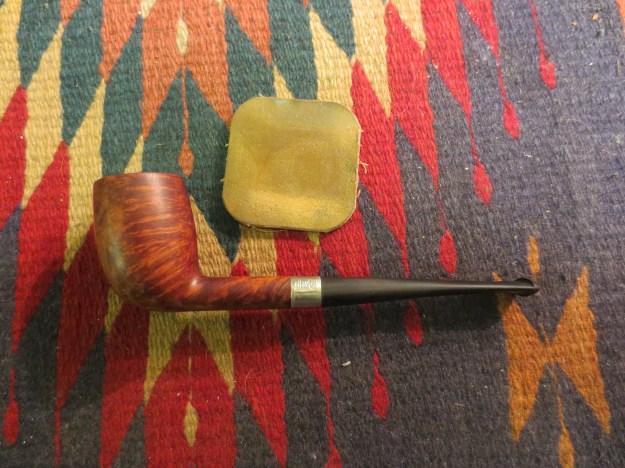

This pipe was another one I got in my trade with Mark, an Irish Seconds made by Peterson. It is stamped on the top of the shank, IRISH SECONDS and on the underside of the shank, Made in the Republic of Ireland. There is no shape number or other stamping on the pipe. The briar is actually very nice except for a flaw that ran around the bottom of the front of the bowl like a smile. It had been filled with white putty that had shrunk and left a shallow groove its entire length (from side to side of the front). The finish was non-existent and I am not sure it ever had been stained. The stem was evidently a replacement and did not fit well against the shank. The diameter of the oval on the shank and that of the stem did not match. The stem was also lopsided at the junction. On the underside of the stem there was a trough carved about ½ inch from the button that functioned as a groove to make the stem a dental bit. It too was poorly executed and was rough. The dimensions on this pipe are diminutive – its length is 5 ¼ inches, height is 1 5/8 and outer diameter of the bowl is 1 ¼ inches. It fits well in the hand and is very light in weight. I suspect that if it were not for the flaw noted above this would have been a higher grade Peterson.

The next photo shows the extent of the flaw and the white fill material on the bottom front of the bowl. This is the only flaw on the bowl.

The next two photos below shows the groove that had been cut in the stem to make it function as a dental bit.

I used a dental pick to remove the white fill material in the flaw and then wiped it clean with acetone. The groove was not deep but it was long and quite wide. I used a combination of briar dust and superglue to replace the fill. I packed the area with briar dust using a dental pick and then dripped superglue into place. While the glue was still wet I quickly put more briar dust on top of the glue and packed it in place as well.

I sanded the stem with 220 grit sandpaper and then a medium grit sanding sponge. I wiped it down with Everclear and then filled the remaining groove with clear superglue until it was a bubble on the surface of the stem. I sanded it with 220 grit sandpaper once it was dry. I sanded the stem shank junction with 220 grit sandpaper to smooth out the transition and make the fit more seamless. I followed that by sanding with a medium and a fine grit sanding sponge to remove the scratches. I was careful in sanding the shank to make the flow of the shank into the stem a gradual incline rather than an abrupt change. I have found that in doing this the stem and shank flow look as close to original as possible.

I sanded the front of the bowl with 220 grit and also with the medium and fine grit sanding sponges. The fill still had spots that needed more work.

I wiped the bowl down with acetone on cotton pads to clean up the finish. I am very happy with the transition from the shank to the bowl.

I did more sanding on the fill on the front of the bowl and refilled the spots that needed work. I stained the bowl with a dark brown aniline stain thinned 2:1 with isopropyl alcohol. I have been using this mixture since I opened the bottle of stain several months ago and now am at the bottom of the bottle so it may be slightly darker.

The stain went into the new fill material but it turned very dark. I continued to apply the stain to the area and flame it repeatedly until the blend was better.

I buffed the pipe with red Tripoli and the White Diamond to see where I stood with the staining.

The fill still stood out as can be seen from the photo below. I decided to continue to apply stain to the surrounding area on the bowl to darken the bottom of the bowl a bit. My thinking was that if the entire bottom of the bowl was slightly darker the fill would blend in better with the briar.

I sanded the stem with my usual array of micromesh pads – wet sanding with 1500-2400 grit sanding pads and dry sanding with 3200-12,000 grit sanding pads. I rubbed the stem down with Obsidian Oil to protect the vulcanite and set is aside to dry.

I buffed the pipe and stem with White Diamond. The photo below shows the finished stem after buffing. The repair of the trough is not visible in the photo and is barely visible when held in the light. I am happy with the repair.

I buffed the entire pipe with White Diamond a final time and then gave it multiple coats of carnauba wax to protect it. I did not want a high gloss on the pipe but rather a slight matte finish. The photos below show the finished pipe. It is ready for many more years of service.