Blog by Steve Laug

Jeff and I have been picking up pipes from a fellow in Los Angeles, California for a few years. We have picked up some excellent pipes from him. This one came to us in September, 2020 (though the photos are stamped April of 2022). It took us awhile to get to the pipe and clean it up. It was a uniquely shaped Freehand that caught our eye. The shape is partially a Dublin but with a pointed heel. There is a carved ring around the top of the bowl setting of a cap. The top of the bowl is almost like a flat hat with a crowned centre portion and small trough between the bowl edge and the crown. The bottom portion of the front of the bowl is flat and shaped like a heart and allows the pipe to be stood on a desk top. The grain on it is stunning with only one small fill/flaw on the left side of the shank ahead of the stamping. It is stamped on the left side and reads City de Luxe [over] GOLD STAR [over] London Made. It is stamped on the right side and reads Made in England [over] UNIQUE in script. There is no shape number on the shank. The stem has an inlaid gold star on the left side of the saddle stem. Jeff took photos of the pipe when it arrived before he started his clean up work.

Jeff and I have been picking up pipes from a fellow in Los Angeles, California for a few years. We have picked up some excellent pipes from him. This one came to us in September, 2020 (though the photos are stamped April of 2022). It took us awhile to get to the pipe and clean it up. It was a uniquely shaped Freehand that caught our eye. The shape is partially a Dublin but with a pointed heel. There is a carved ring around the top of the bowl setting of a cap. The top of the bowl is almost like a flat hat with a crowned centre portion and small trough between the bowl edge and the crown. The bottom portion of the front of the bowl is flat and shaped like a heart and allows the pipe to be stood on a desk top. The grain on it is stunning with only one small fill/flaw on the left side of the shank ahead of the stamping. It is stamped on the left side and reads City de Luxe [over] GOLD STAR [over] London Made. It is stamped on the right side and reads Made in England [over] UNIQUE in script. There is no shape number on the shank. The stem has an inlaid gold star on the left side of the saddle stem. Jeff took photos of the pipe when it arrived before he started his clean up work.

He took close up photos of the rim top and stem to give a clear idea of the condition of the pipe. The bowl had a thick cake and a heavy overflow of lava on the inner edge and top of the rim at the back of the bowl. The stem is heavily oxidized and had tooth chatter and marks on both sides ahead of the button.

He took close up photos of the rim top and stem to give a clear idea of the condition of the pipe. The bowl had a thick cake and a heavy overflow of lava on the inner edge and top of the rim at the back of the bowl. The stem is heavily oxidized and had tooth chatter and marks on both sides ahead of the button.

Jeff took photos of the bowl from various angles to show the condition of the briar and the style of the pipe. It is a beautiful pipe under the grime and grit of the years.

Jeff took photos of the bowl from various angles to show the condition of the briar and the style of the pipe. It is a beautiful pipe under the grime and grit of the years.  Jeff captured the stamping on the shank sides and the left side of the stem. It is clear and readable as noted above. You can see the fill/flaw in the first photo to the left of the London Made stamp. There is a fill there that is partially missing and will need to be replaced.

Jeff captured the stamping on the shank sides and the left side of the stem. It is clear and readable as noted above. You can see the fill/flaw in the first photo to the left of the London Made stamp. There is a fill there that is partially missing and will need to be replaced.

This pipe was quite stunning under the grime and has beautiful straight grain. From what I can see there is one small flaw with a damaged fill on the left side of the shank and otherwise nothing else. I decided to do some digging into the City Gold Star stamp and see what I could learn. I turned first to Pipephil (http://pipephil.eu/logos/en/logo-c5.html). There was an example of the City Gold Star but it was a French Made pipe while the one I am working on is Made in England. The example is stamped Unique like the one I have. There are no shape numbers on it either. There is a tie to GBD and generally the pipe is a second for that brand. Perhaps the flaw that I mention above is what kept it from being a GBD Unique and relegated it to City de Luxe status. Truly though it is a small flaw on an otherwise stunning pipe. I have included a screen capture of the pipe from PipePhil below.

This pipe was quite stunning under the grime and has beautiful straight grain. From what I can see there is one small flaw with a damaged fill on the left side of the shank and otherwise nothing else. I decided to do some digging into the City Gold Star stamp and see what I could learn. I turned first to Pipephil (http://pipephil.eu/logos/en/logo-c5.html). There was an example of the City Gold Star but it was a French Made pipe while the one I am working on is Made in England. The example is stamped Unique like the one I have. There are no shape numbers on it either. There is a tie to GBD and generally the pipe is a second for that brand. Perhaps the flaw that I mention above is what kept it from being a GBD Unique and relegated it to City de Luxe status. Truly though it is a small flaw on an otherwise stunning pipe. I have included a screen capture of the pipe from PipePhil below. I am also including information from the side bar. I wonder if the Gold Star is a step up from the normal City de Luxe. If so that would explain the stamping on this pipe.

I am also including information from the side bar. I wonder if the Gold Star is a step up from the normal City de Luxe. If so that would explain the stamping on this pipe.

While the City de Luxe logo is a silver outline star, this one is a solid gold color star. This GBD second was crafted in the French facilities of the brand.

I turned then to the article on Pipedia about GBD pipes (https://pipedia.org/wiki/GBD). I quote a section from the article that talked about the introduction of the City Deluxe sub brand.

The solid demand for GBD pipes also encouraged the management to introduce a number of sub brands designed to win new buyers. We can list such sub brands as follows:

- The City de Luxe (1921) had an inserted star on the stem as trademark and were marketed in England and in France. These pipes were the bestseller of the 5½ Shilling class in the 1930s in Great Britain.

- Reserved for the French market remained the even more favorable GBD brand Marcee, a derivative of Marechal Ruchon & Co. Ltd. that was offered until the 2nd World War and for another one or two years afterwards.

- The Camelia – made in London as a 2½ Shilling line – was only around for a few years.

- Important to mention is also the Riseagle—completely produced in Paris before the wartime for England’s smokers who wanted “a cheap but dependable British made pipe”… one of the most successful 1 Shilling pipes until 1939! The introduction of the luxury impact on the excise tax for pipes after the war put an end to this cheap brand.

The section on City de Luxe had a link to another article on Pipedia specifically on the brand so I followed the link (https://pipedia.org/wiki/City_de_Luxe). There was a short article and I quote from it below.

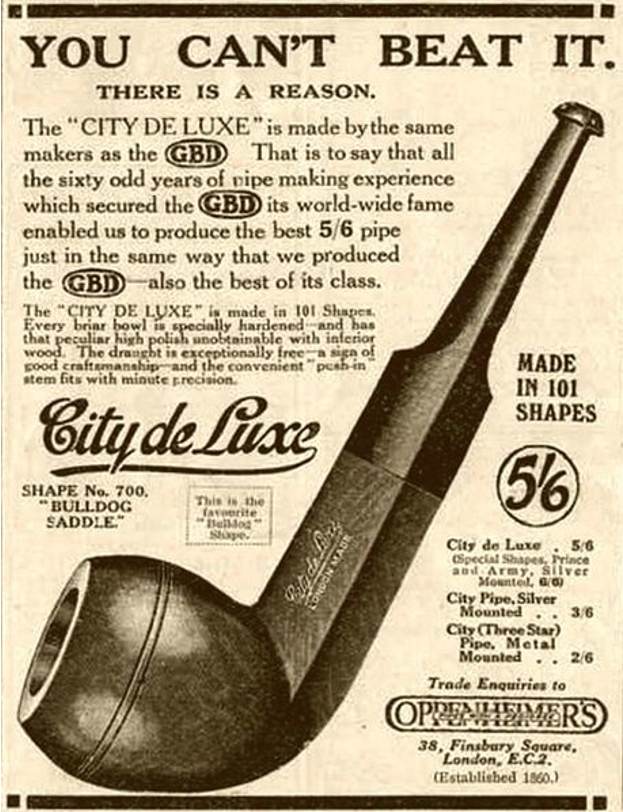

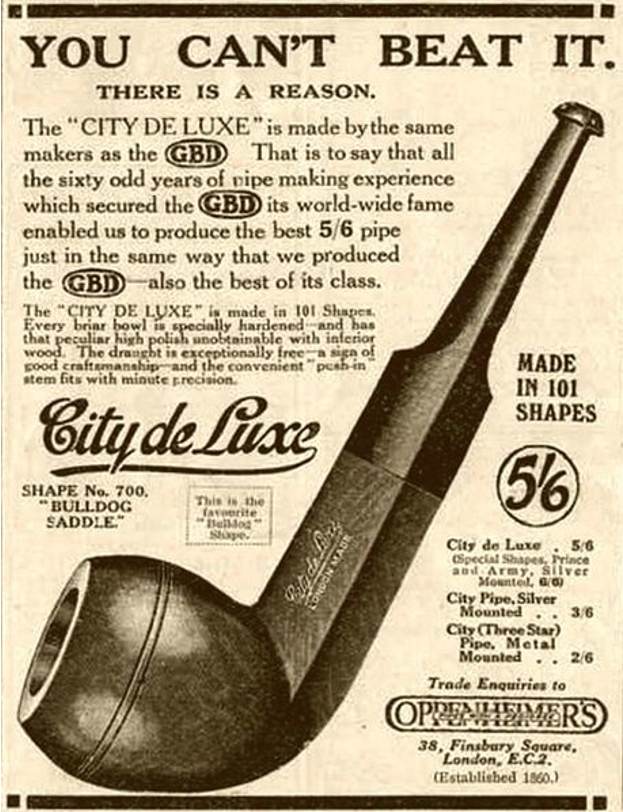

City De Luxe was a sub brand of GBD and Oppenheimer Pipe started in 1921 and for a time the most popular pipe in the 5/6 shilling range of pipes in Britain in the 1930s.

The trademark of the line was an inserted star on the stem, and pipes were made with both English and French markings. For more information see GBD.

I knew that the brand started in 1921 and hit is height in the 1930s. I have included an advertisement from the page below that has some great lines about the brand. With that information I knew what I was working on – a sub brand of GBD and a step up from the City de Luxe – a City Gold Star. Now I wanted to know about the Unique stamp on the shank side. What did it mean? There was nothing on either the City de Luxe article or on the City Gold Star article that referred to that. There was a photo of a pipe stamped City Gold Star but no data regarding the Unique. So I went back to the GBD article and followed the link to GBD Model Information (https://pipedia.org/wiki/GBD_Model_Information). I found the unique listed there and quote that below.

With that information I knew what I was working on – a sub brand of GBD and a step up from the City de Luxe – a City Gold Star. Now I wanted to know about the Unique stamp on the shank side. What did it mean? There was nothing on either the City de Luxe article or on the City Gold Star article that referred to that. There was a photo of a pipe stamped City Gold Star but no data regarding the Unique. So I went back to the GBD article and followed the link to GBD Model Information (https://pipedia.org/wiki/GBD_Model_Information). I found the unique listed there and quote that below.

Unique — England, unknown if also made in France: smooth freehand shapes, mostly large/oversized pipes. Possible made by the Jameson brothers. –TH

This led me to more questions so I turned back to the GBD article to see if I could find some answers to those questions (https://pipedia.org/wiki/GBD). The major questions I had were as follows.

- Where did the Uniques fit in the hierarchy of GBD pipes?

- When did they come out?

- Who carved them? (Remember the quote above that they were possibly made by the Jameson brothers.)

I found a section on that hidden in the middle of the article. I quote the pertinent paragraphs below.

The premium lines of GBD offered very good values, and are considered amongst the most affordable high end pipe of the 1960’s and earlier and a rival in quality, design, and price to Dunhill. Smokers’ Haven was the main retail supplier for GBD’s in the US until the early 1980’s.

GBD produced consistently well made pipes, almost entirely of Algerian or Grecian briar. In the late 1960’s to late 1970’s, they introduced the “Collector” and “Unique” lines, made primarily by Horry Jamieson, who had carved for Barling for many years, and was skilled in freehand design. Older GBD pieces are excellent smokers and unique in design. They did an excellent executions of classic pipe shapes, as well as some beautiful freehands in the “Unique” line. [2]

These paragraphs answered my questions. The Unique line was made in the late 1960s to late 1970s and were primarily carved by Horry Jameson. The line was created at the height of the Freehand craze in the US and introduced some beautiful GBD Freehands. Now I knew that I working on a pipe from that time period, carved by Jameson. The fact that it was not a GBD Unique but lower in the hierarchy in the City de Luxe line was because of the small flaw/fill on the left side of the shank ahead of the stamping. The grain otherwise is stellar and the shape is worthy of the UNIQUE stamping.

Armed with that information I turned to work on the pipe itself. Before he sent it to me, Jeff had cleaned up the pipe with his usual cleaning process. He reamed the pipe with a PipNet pipe reamer and removed the rest of it with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with isopropyl alcohol, cotton swabs and pipe cleaners. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and then rinsed it off with warm water. He scrubbed the stem with Soft Scrub and a tooth brush and rinsed it off with warm water. It looked amazing when I took it out of the package of pipes he shipped me. So much so that it is the second of those pipes that I chose to work on. I took photos of the pipe before I started my part of the restoration work.

The rim top and the inner and outer edges of the bowl all look very good. The lava on the surface and inner edge is gone. It was thick enough that it protected the rim and edges from damage. The stem surface looked good with the oxidation gone and light tooth chatter on either side of the stem.

The rim top and the inner and outer edges of the bowl all look very good. The lava on the surface and inner edge is gone. It was thick enough that it protected the rim and edges from damage. The stem surface looked good with the oxidation gone and light tooth chatter on either side of the stem.  The stamping on the sides of the shank and on the gold star is clear and readable as noted above.

The stamping on the sides of the shank and on the gold star is clear and readable as noted above. I removed the stem and took a photo of the pipe to give a sense of the whole. It is a beautiful pipe that really flows with the grain on the briar.

I removed the stem and took a photo of the pipe to give a sense of the whole. It is a beautiful pipe that really flows with the grain on the briar. I took some photos of the uniqueness of the sitter shape and the flat heart on the front of the bowl. It is a nice looking pipe.

I took some photos of the uniqueness of the sitter shape and the flat heart on the front of the bowl. It is a nice looking pipe.

I started my work on the pipe by addressing the flaw/fill on the left side of the shank. I have drawn a red box around it to clearly identify it for you. I filled in the area and repaired the fill with clear CA glue and briar dust working it into the area with a toothpick. I set it aside to cure and once the glue hardened I sanded it smooth with 220 grit sandpaper to blend it in. I started polishing that area with 400 grit wet dry sandpaper. I touched up the area around the repaired fill with an Oak Stain Pen to blend it into the shank colour.

I started my work on the pipe by addressing the flaw/fill on the left side of the shank. I have drawn a red box around it to clearly identify it for you. I filled in the area and repaired the fill with clear CA glue and briar dust working it into the area with a toothpick. I set it aside to cure and once the glue hardened I sanded it smooth with 220 grit sandpaper to blend it in. I started polishing that area with 400 grit wet dry sandpaper. I touched up the area around the repaired fill with an Oak Stain Pen to blend it into the shank colour.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad to remove the sanding dust.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad to remove the sanding dust.

The bowl looked very good at this point so I rubbed it down with Before & After Restoration Balm. I worked it into the surface of the bowl and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for about 10-15 minutes and buffed with a cotton cloth to raise the shine.

The bowl looked very good at this point so I rubbed it down with Before & After Restoration Balm. I worked it into the surface of the bowl and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for about 10-15 minutes and buffed with a cotton cloth to raise the shine.

I set the bowl aside and turned to work on the stem. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I set the bowl aside and turned to work on the stem. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Beautifully Grained GBD Made City de Luxe Gold Star Unique is a great looking pipe now that it has been restored. The shape of the bowl follows the grain and highlights the beauty of the briar. The rich brown stain works well with the polished vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished GBD Made Unique Freehand is a large pipe that will be great for sitting and reading on the porch. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ¾ inches, Height: 2 ¾ inches, Outside diameter of the bowl: 2 inches, Chamber diameter: 1 inch. The weight of the pipe is 73 grams/2.54 ounces. This is one gorgeous pipe. It is one that I will be adding shortly to the British Pipe Makers section of the rebornpipes store. I take a moment to remind myself and each of us that we are trustees of pipes that will outlive us and the lives of many other pipe men and women who carry on the trust of their care and use. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This Beautifully Grained GBD Made City de Luxe Gold Star Unique is a great looking pipe now that it has been restored. The shape of the bowl follows the grain and highlights the beauty of the briar. The rich brown stain works well with the polished vulcanite stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished GBD Made Unique Freehand is a large pipe that will be great for sitting and reading on the porch. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ¾ inches, Height: 2 ¾ inches, Outside diameter of the bowl: 2 inches, Chamber diameter: 1 inch. The weight of the pipe is 73 grams/2.54 ounces. This is one gorgeous pipe. It is one that I will be adding shortly to the British Pipe Makers section of the rebornpipes store. I take a moment to remind myself and each of us that we are trustees of pipes that will outlive us and the lives of many other pipe men and women who carry on the trust of their care and use. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This pipe doesn’t have the old orific button, but it might date from just after that time period. Anyway, time to get to work! I started by sending the stinger for a soak in some lemon-infused isopropyl alcohol. I let it sit for several hours, cleaned it off and gave it a quick polish. Good as new!

This pipe doesn’t have the old orific button, but it might date from just after that time period. Anyway, time to get to work! I started by sending the stinger for a soak in some lemon-infused isopropyl alcohol. I let it sit for several hours, cleaned it off and gave it a quick polish. Good as new! The shank had a lovely, thin band around it – but it was quite encrusted. I removed it, looked closer, and saw that there was rust! Interesting – the band must have some iron in it. I dropped the band in a little plastic bowl of plain white vinegar and let it soak overnight. I scrubbed with some 0000-grit steel wool and that worked a treat. Gave it a quick polish with my Micromesh pads and it looked good as new.

The shank had a lovely, thin band around it – but it was quite encrusted. I removed it, looked closer, and saw that there was rust! Interesting – the band must have some iron in it. I dropped the band in a little plastic bowl of plain white vinegar and let it soak overnight. I scrubbed with some 0000-grit steel wool and that worked a treat. Gave it a quick polish with my Micromesh pads and it looked good as new.

Next, I went to work on the long stem. It appears to be acrylic – definitely not vulcanite. I gave it a good wipe-down with some soap on cotton rounds and that helped. As mentioned earlier, I don’t think this pipe was smoked and, though I can’t be sure about that, the stem’s insides had dust-type filth rather than tobacco debris. Regardless, I cleaned it out with pipe cleaners and 99% isopropyl alcohol. It wasn’t too dirty.

Next, I went to work on the long stem. It appears to be acrylic – definitely not vulcanite. I gave it a good wipe-down with some soap on cotton rounds and that helped. As mentioned earlier, I don’t think this pipe was smoked and, though I can’t be sure about that, the stem’s insides had dust-type filth rather than tobacco debris. Regardless, I cleaned it out with pipe cleaners and 99% isopropyl alcohol. It wasn’t too dirty.

Fortunately, the stem was in good enough shape that it didn’t show any tooth marks/dents. So, I skipped the cyanoacrylate treatments and jumped straight to the Micromesh pads. I used all nine pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing (from 3,600 onward).

Fortunately, the stem was in good enough shape that it didn’t show any tooth marks/dents. So, I skipped the cyanoacrylate treatments and jumped straight to the Micromesh pads. I used all nine pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing (from 3,600 onward). Now for the stummel. As the photos show, the finish on the wood has crackled and/or degraded somewhat over the years. It looks terrible and I’ll have to address that. First, I decided to ream out the bowl – but there wasn’t anything to ream! This is another clue that suggests an unsmoked pipe. It was certainly dusty inside – very. I cleaned out the insides with pipe cleaners and 99% isopropyl alcohol. I also cleaned the insides with some soap and tube brushes. It was nice and clean after this.

Now for the stummel. As the photos show, the finish on the wood has crackled and/or degraded somewhat over the years. It looks terrible and I’ll have to address that. First, I decided to ream out the bowl – but there wasn’t anything to ream! This is another clue that suggests an unsmoked pipe. It was certainly dusty inside – very. I cleaned out the insides with pipe cleaners and 99% isopropyl alcohol. I also cleaned the insides with some soap and tube brushes. It was nice and clean after this. Now to deal with the finish on the stummel. I grabbed some Murphy’s and rubbed the surface to clean things up. This did precious little. Since there was a fill that also needed to be fixed under this finish, I took some acetone and thoroughly cleaned the surface – that was the best decision I made! The pipe looked so much better with the old finish removed. There was actually some very nice wood under there.

Now to deal with the finish on the stummel. I grabbed some Murphy’s and rubbed the surface to clean things up. This did precious little. Since there was a fill that also needed to be fixed under this finish, I took some acetone and thoroughly cleaned the surface – that was the best decision I made! The pipe looked so much better with the old finish removed. There was actually some very nice wood under there.

I examined the nicks in the briar. I took my iron and a damp cloth to try to raise them. The hot and moist steam can often cause the wood to swell slightly and return to shape. This worked well – I was pleased with the results. However, some lumps and bumps remained on the rim and a big fill to boot. In order to safely remove the marks on the rim, I “topped” the pipe – that is to say, I gently and evenly sanded down the rim on a piece of 220-grit sandpaper. This effectively removed the damage, without altering the look of the pipe.

I examined the nicks in the briar. I took my iron and a damp cloth to try to raise them. The hot and moist steam can often cause the wood to swell slightly and return to shape. This worked well – I was pleased with the results. However, some lumps and bumps remained on the rim and a big fill to boot. In order to safely remove the marks on the rim, I “topped” the pipe – that is to say, I gently and evenly sanded down the rim on a piece of 220-grit sandpaper. This effectively removed the damage, without altering the look of the pipe.

Then, I made a mix of cyanoacrylate and briar dust and filled the fill. I sanded the repair down with 400-grit sandpaper, then proceeded to use the Micromesh pads over the whole thing. Oh boy, it really looked good.

Then, I made a mix of cyanoacrylate and briar dust and filled the fill. I sanded the repair down with 400-grit sandpaper, then proceeded to use the Micromesh pads over the whole thing. Oh boy, it really looked good.

I glued the band back on the shank and applied some Before & After Restoration Balm. I let it sit for 20 minutes or so. It does lovely things to the wood. I polished it with a microfibre cloth and it shone. Wow – the pipe really looks lovely.

I glued the band back on the shank and applied some Before & After Restoration Balm. I let it sit for 20 minutes or so. It does lovely things to the wood. I polished it with a microfibre cloth and it shone. Wow – the pipe really looks lovely.