Blog by Steve Laug

The next pipe on the work table came to us from an antique store in Houston, Texas in Nov. 2019 when Jeff was there for his eldest son’s wedding. It has been around waiting to be worked on. Jeff did the original photographs of the pipe in December 2019. It is a straight Brandy with an acrylic stem and some nice grain around the bowl. The stamping is the clear and readable. It is stamped on the left side of the shank and reads the Cesare [over] Suprema 2. On the underside of the shank it is stamped with the shape number 111. The finish was rough with a lot scratches and nicks in the briar. There was a small burn mark on the lower right side of the bowl toward the front where the pipe obviously had been laid against a hot ash in an ashtray. There was a lot of grime ground into the bowl and some darkening around the sides of the bowl. There was some damage on the crowned rim top where the finish was worn off and scratched. The bowl was heavily caked and there was a light lava coat on the scratched top of the rim. Surprisingly the inner edge of the bowl looked quite good under the grime. The black, taper acrylic stem was a mess. There were tooth marks and chatter on both sides and damage on the button surface. The stem had grey acrylic insert on the top side of the taper. The pipe had promise but it was very dirty. Jeff took photos of the pipe before he started his cleanup work.

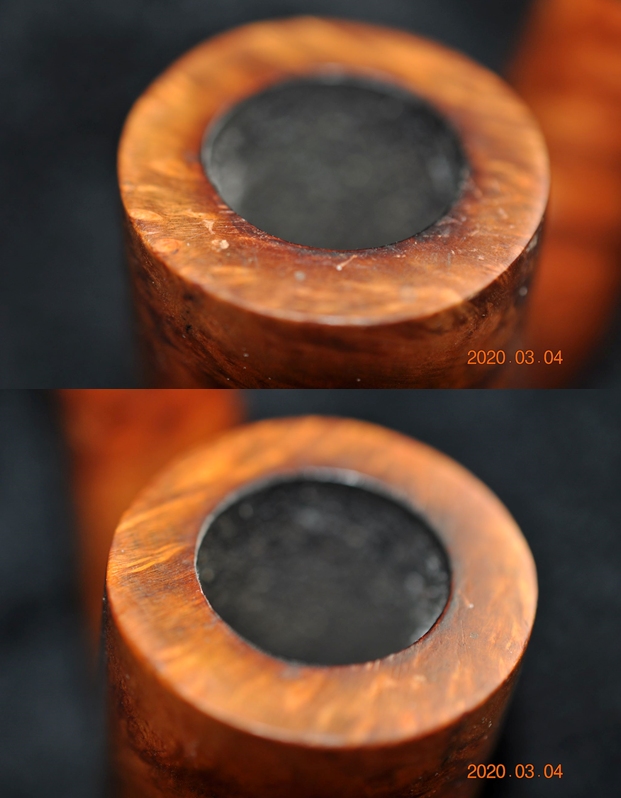

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and the condition of the rim top and edges. You can see the damage on the crowned top and edges of the bowl. He also took photos of the top and underside of the stem to show the horrible condition of the chatter and tooth marks.

He took photos of the rim top and bowl to give a clear picture of the thickness of the cake and the condition of the rim top and edges. You can see the damage on the crowned top and edges of the bowl. He also took photos of the top and underside of the stem to show the horrible condition of the chatter and tooth marks.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar around the pipe looked like. There is some interesting grain under the grime and heavy scratching of the bowl sides. There are a few small fills that also evident. The third photo shows the burn mark toward the front bottom of the bowl.

Jeff took photos of the sides and heel of the bowl to give a picture of what the briar around the pipe looked like. There is some interesting grain under the grime and heavy scratching of the bowl sides. There are a few small fills that also evident. The third photo shows the burn mark toward the front bottom of the bowl.

Jeff took photos of the stamping on the left and underside of the shank. It read as noted above.

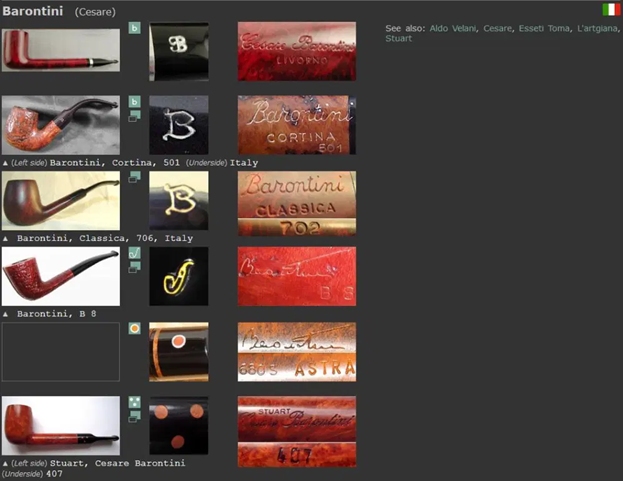

Jeff took photos of the stamping on the left and underside of the shank. It read as noted above.  I searched on Pipephil for the brand and found the stamping and logo on a similar looking pipe. There is a listing at the bottom of the screen capture of a Suprema 4 with the same Cesare signature on the shank side (http://www.pipephil.eu/logos/en/logo-c3.html). It also confirmed a faint memory that I had about a connection to Barontini.

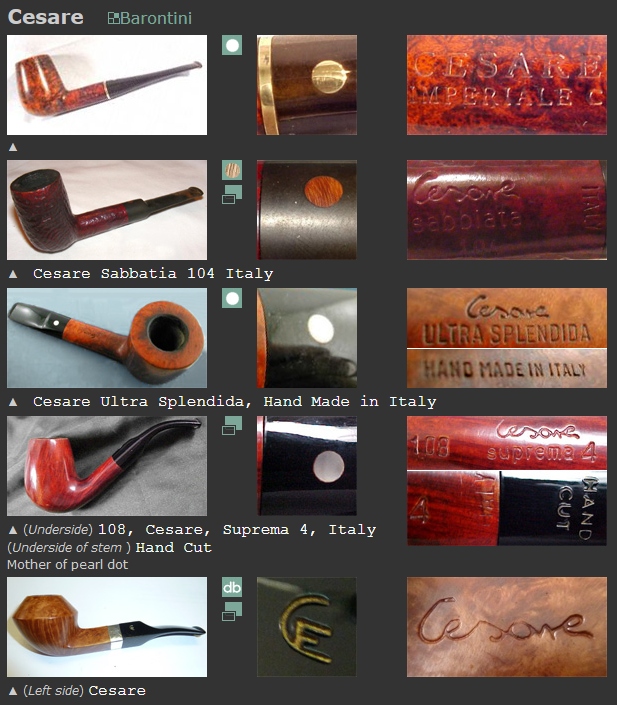

I searched on Pipephil for the brand and found the stamping and logo on a similar looking pipe. There is a listing at the bottom of the screen capture of a Suprema 4 with the same Cesare signature on the shank side (http://www.pipephil.eu/logos/en/logo-c3.html). It also confirmed a faint memory that I had about a connection to Barontini. I turned to Pipedia for information on the brand (https://pipedia.org/wiki/Barontini,_Cesare). I had seen the connection on Pipephil with Barontini so it was not surprising to see that the maker was Cesare Barontini. I quote from the site:

I turned to Pipedia for information on the brand (https://pipedia.org/wiki/Barontini,_Cesare). I had seen the connection on Pipephil with Barontini so it was not surprising to see that the maker was Cesare Barontini. I quote from the site:

In 1890 Turildo Barontini opened a factory for the production of briar. In 1925 his son Bruno began to produce the first pipes. Cesare Barontini, son of Bruno, started direction of the factory in 1955, and still runs it together with his daughters Barbara and Silvia.

There was also a list of the Barontini sub-brands and seconds. I am including them below because of the many recognizable brands listed.

Aldo Velani, Cesare, L’artigiana, Stuart, Cortina. See also Barontini, Ilio, Cesare’s cousin.

I knew that the pipe I was working came from Cesare Barontini and the Barontini Factory in Italy. Now it was time to work on the pipe itself.

Since Jeff follows the same pattern of work in his cleanup we do not include photos but rather just a simple summary. Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove much of the varnish coat from the rim top and you could see the damages to the front edge of the rim. He cleaned the internals and externals of the stem with alcohol, pipe cleaners and cotton swabs. The stem was clean and you could clearly see the damage on the top and underside. I took photos of what the pipe looked like when I brought to my worktable.

The bowl and rim top cleaned up really well leaving the nicks and scratches on the crown visible. The finish was worn off the rim top so it was rough to touch. The inner and outer edges of the bowl were surprisingly smooth. The stem surface looked very good the tooth chatter and marks on both sides ahead of the button very visible.

The bowl and rim top cleaned up really well leaving the nicks and scratches on the crown visible. The finish was worn off the rim top so it was rough to touch. The inner and outer edges of the bowl were surprisingly smooth. The stem surface looked very good the tooth chatter and marks on both sides ahead of the button very visible.  I took a photo of the stamping on the left and underside of the shank. It read as noted above.

I took a photo of the stamping on the left and underside of the shank. It read as noted above.  I removed the stem and took a photo of the pipe to give a sense of the whole. It is a well shaped tall Brandy shape that looks elegant.

I removed the stem and took a photo of the pipe to give a sense of the whole. It is a well shaped tall Brandy shape that looks elegant. Now it was time to do my work on the pipe. To minimize many of the nicks and scratches on the sides, bottom and top of the bowl I steamed them out. I heat a butter knife on our gas range and use a damp cloth to cover the nicks around the bowl. I heat the knife until it hot and then place it over the cloth. I creates steam which lifts many of the scratches in the briar. I was able to remove many of them. The few that remain are a part of this pipe’s journey.

Now it was time to do my work on the pipe. To minimize many of the nicks and scratches on the sides, bottom and top of the bowl I steamed them out. I heat a butter knife on our gas range and use a damp cloth to cover the nicks around the bowl. I heat the knife until it hot and then place it over the cloth. I creates steam which lifts many of the scratches in the briar. I was able to remove many of them. The few that remain are a part of this pipe’s journey.  I polished the bowl and the rim top, sides and shank with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. I carefully avoided the stamping on the top and underside of the shank so as not to damage the stamping.

I polished the bowl and the rim top, sides and shank with micromesh sanding pads – wet sanding with 1500-12000 grit pads and wiping it down after each pad with a damp cloth. I carefully avoided the stamping on the top and underside of the shank so as not to damage the stamping.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. It helped to blend the stain into the rest of the bowl. The final buffing would bring the pipe alive.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. It helped to blend the stain into the rest of the bowl. The final buffing would bring the pipe alive.

I set the bowl aside and turned my attention to the stem. I filled in the tooth marks on the topside and the underside of the stem with black super glue. I also rebuilt the button surface on both sides.

I set the bowl aside and turned my attention to the stem. I filled in the tooth marks on the topside and the underside of the stem with black super glue. I also rebuilt the button surface on both sides. Once the repairs cured I used a needle file to flatten the repairs and recut the button. I used 220 grit sandpaper to smooth out the repairs further and blend them into the stem surface. I started the polishing with 400 grit wet dry sandpaper.

Once the repairs cured I used a needle file to flatten the repairs and recut the button. I used 220 grit sandpaper to smooth out the repairs further and blend them into the stem surface. I started the polishing with 400 grit wet dry sandpaper.

I polished the acrylic stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the acrylic stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This well made, classic Cesare Suprema 2 Tall Brandy with a black acrylic stem is a great looking pipe now that it has been restored. I was able to remove and minimize the scratches around the bowl and rim. The rich brown finish came alive with the polishing and waxing. The grain really popped. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Cesare Brandy is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This well made, classic Cesare Suprema 2 Tall Brandy with a black acrylic stem is a great looking pipe now that it has been restored. I was able to remove and minimize the scratches around the bowl and rim. The rich brown finish came alive with the polishing and waxing. The grain really popped. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Cesare Brandy is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!