Blog by Steve Laug

Give the previous blogs a read to have an idea about the Bertram Collection that I am working on these days. I can’t adequately describe how overwhelmed I am when I look at the 200+ pipes that need to be restored but there is only one way to move ahead – 1 pipe at a time. Jeff is doing the major cleanup on the lot as that would be more than I could handle by myself in moving through this many pipes. From his cleaned pipes the next one I chose is a Made in London National Washington, D.C. 33 Bent Billiard to be the next pipe that I would work on. It has some amazing straight grain around the bowl and shank. The bowl had cake in the chamber that was no problem. The rim top had some darkening and lava overflow on the back side. The inner and outer edge of the bowl appeared to be in good condition but we would know more once the bowl had been reamed and cleaned. The exterior of the briar looked lifeless and was dusty with the grime of years of storage. The stem had some oxidation, tooth chatter and marks near the button on both sides. Jeff took some photos of the pipe before he began his cleanup work on it.

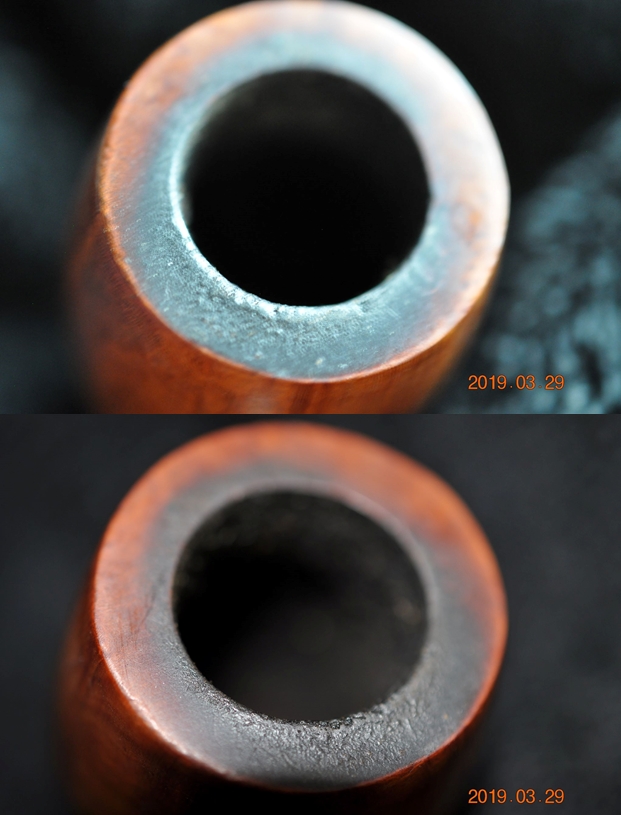

Jeff took close-up photos of the bowl and rim to capture the condition of the pipe when it arrived. The rim top had a thick coat of lava and the bowl had a thick cake. It was hard to see what the inner and outer edge looked like with the cake and lava.

Jeff took close-up photos of the bowl and rim to capture the condition of the pipe when it arrived. The rim top had a thick coat of lava and the bowl had a thick cake. It was hard to see what the inner and outer edge looked like with the cake and lava. Jeff took a picture of the bowl side and the heel to show the marvelous grain on the bowl. It really is quite stunning and very dirty! There is also something mis-stamped on right side of the bowl. Under a magnifying lens it reads England.

Jeff took a picture of the bowl side and the heel to show the marvelous grain on the bowl. It really is quite stunning and very dirty! There is also something mis-stamped on right side of the bowl. Under a magnifying lens it reads England. The next two photos show the stamping on the sides of the shank. The left side is stamped with National over Washington, D.C. over Made in London. At the shank/bowl junction it is stamped 33. The stamping on the shank was slightly double stamped and had some white paint in it.

The next two photos show the stamping on the sides of the shank. The left side is stamped with National over Washington, D.C. over Made in London. At the shank/bowl junction it is stamped 33. The stamping on the shank was slightly double stamped and had some white paint in it. The next two photos show the condition of the stem surfaces. The stem was oxidized and had some calcification on the surface as well as tooth marks and chatter on both sides near the button.

The next two photos show the condition of the stem surfaces. The stem was oxidized and had some calcification on the surface as well as tooth marks and chatter on both sides near the button. I have already done the work on one of the National pipes in the Bertram lot so I turned to that to have another look at the history of the brand (https://rebornpipes.com/2019/05/21/doing-some-cosmetic-work-on-a-national-pipes-rhodesian/). I quote in full from that blog.

I have already done the work on one of the National pipes in the Bertram lot so I turned to that to have another look at the history of the brand (https://rebornpipes.com/2019/05/21/doing-some-cosmetic-work-on-a-national-pipes-rhodesian/). I quote in full from that blog.

Before I started my restoration work I wanted to refresh my memory about the brand. I remembered from previous National Pipes that I had worked on that there was a tie to the Bertram Pipe Company in Washington, D.C. I also knew that it was a very different company than the National Briar Pipe Company of Jersey City, New Jersey but that is where all the trails let in terms of Pipedia and Pipephil’s site. I turned back to a previous blog that I had written on the brand when I restored a pipe with the same stampings to review the history and connection of the brand to Bertram. https://rebornpipes.com/tag/national-washington-d-c-pipes/. I knew that the fact that there were several of these included with the large lot of Bertram pipes that Jeff and I purchased was not accidental. Here is the link to that previous blog. I quote in part:

I had a gut feeling that the pipe had some connection to Bertram Pipe Company of Washington DC but only the vaguest memory of that connection. I could not remember where I picked that up but just had the memory. I did some searching on the Internet and found a National Briar Pipe Company of Jersey City, New Jersey with no clear ties to Washington DC on the Pipedia site. This was the company that purchased the Doodler after Tracy Mincer died. I could see that the Jersey City pipes were stamped differently and all had line names stamped on them. On the Pipephil site I found an English version that had very different stamping on the left side of the shank as well as Made in England on the right side of the shank.

Thus I was reminded of the non-connection to the New Jersey Pipe Company. The blog went on to record some information that tied the National Washington, D.C. company to Bertram more definitively. I quote

I…posted a question on Smokers Forum (SF) and Pipe Smokers Unlimited regarding the brand. I received several responses that gave me information. One of them on SF came from Ed Klang and provided me with some confirmation regarding my memory of the connection with Bertram. I quote him in full, “In the history of the Bertram company, after the fire at the Washington, D.C. facility and the decision was made to discontinue Bertram production a group of employees and a few investors wanted to buy the rights to the Bertram name, which was turned down and it was then proposed that they would rebrand the pipes as National, no mention was made whether anything ever came of that proposal. Supposedly this group did produce pipes for a while but the effort was finally abandoned and I have never been able to reliably confirm this. Just bits and pieces here and there.” Thanks Ed. This is the random memory that I was trying to dig up.

I also received a reply on SF from Radiobob that read as follows: “National Pipe and Tobacco was located on the 1700 block of Pennsylvania Avenue in Washington, D.C., just about a block from where I worked. I still have two Canadians that I bought there, as well as a Comoy’s Patina Apple. In my recollection, it closed down–much to my regret–in the mid to late 1980s.”

Those responses gave me the kind of details that I always find helpful in my restoration work. I will continue to do some digging on the company and see what I can find but that bit confirmed the visual tie to the Bertram Company of DC. Thank you for your help Ed and Bob.

Now I have a different one that has the National stamp and also is stamped Made in London. There is also a mistaken stamp on the side of the bowl that says ENGLAND. This is another piece of the puzzle for me. I know National had other pipe companies in Europe make there pipes. This one has a very Barling like look to it. I wonder if it was not made by them for National? On with the cleanup and restoration on this Bent Billiard.

When I received the pipe Jeff had already reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He had scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He had scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He had rinsed it under running water. He dried it off with a soft cloth. He was able to remove lava build up on the rim top and you could see the great condition of the bowl top and edges of the rim. There was still some darkening to the rim top toward the back of the bowl. He soaked the stem in Before & After Deoxidizer to remove the oxidation. I took photos of the pipe before I started my work on it.

I took a close up photo of the rim top to show the condition of the bowl and rim after Jeff had cleaned up the grime and lava. The inner edge of the rim has some damage and nicks on it. The out edge of the rim looks good. There is some rim darkening on the back side of the bowl. The stem photos show that the oxidation is gone. The surface of the vulcanite looked very good. The tooth marks and chatter are near the button on both sides.

I took a close up photo of the rim top to show the condition of the bowl and rim after Jeff had cleaned up the grime and lava. The inner edge of the rim has some damage and nicks on it. The out edge of the rim looks good. There is some rim darkening on the back side of the bowl. The stem photos show that the oxidation is gone. The surface of the vulcanite looked very good. The tooth marks and chatter are near the button on both sides.  I also took a photo of the stamping on the left side of the shank showing how the stamping was laid out. It appeared to have been double stamped and the stamping whitened. There was also a strange mistaken stamping on the right side of the bowl – it read ENGLAND.

I also took a photo of the stamping on the left side of the shank showing how the stamping was laid out. It appeared to have been double stamped and the stamping whitened. There was also a strange mistaken stamping on the right side of the bowl – it read ENGLAND. I worked on the inner edge of the rim and the darkening on the backside of the top with a folded piece of 220 grit sandpaper to smooth out the damage and remove the darkening.

I worked on the inner edge of the rim and the darkening on the backside of the top with a folded piece of 220 grit sandpaper to smooth out the damage and remove the darkening.  There were two noticeable divots in the otherwise flawless briar – one on the left side of the heel of the bowl and the other on the right side of the shank. I darkened them with a black Sharpie pen and then filled them in with clear super glue. Once the repair cured I sanded it smooth with 220 grit sandpaper and smoothed further with 400 grit sandpaper.

There were two noticeable divots in the otherwise flawless briar – one on the left side of the heel of the bowl and the other on the right side of the shank. I darkened them with a black Sharpie pen and then filled them in with clear super glue. Once the repair cured I sanded it smooth with 220 grit sandpaper and smoothed further with 400 grit sandpaper.

I polished the bowl and rim top with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each pad to remove the sanding debris. After the final sanding pad I hand buffed it with a cotton cloth to raise a shine.

I polished the bowl and rim top with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I wiped the bowl down with a damp cloth after each pad to remove the sanding debris. After the final sanding pad I hand buffed it with a cotton cloth to raise a shine.

I worked some Before & After Restoration Balm into finish of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Restoration Balm really makes the grain stands out beautifully. Between the polishing with the micromesh pads and the balm I did not have to stain the repaired areas. They blend in very well.

I worked some Before & After Restoration Balm into finish of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Restoration Balm really makes the grain stands out beautifully. Between the polishing with the micromesh pads and the balm I did not have to stain the repaired areas. They blend in very well.

I set the bowl aside and worked on the stem. I used a folded piece of 220 grit sandpaper to blend the tooth marks and chatter into the surface of the stem. Once the surface was smooth I sanded out the scratch marks and started the polishing of the stem with a folded piece of 400 grit sandpaper. I wiped the stem down with Obsidian Oil.

I set the bowl aside and worked on the stem. I used a folded piece of 220 grit sandpaper to blend the tooth marks and chatter into the surface of the stem. Once the surface was smooth I sanded out the scratch marks and started the polishing of the stem with a folded piece of 400 grit sandpaper. I wiped the stem down with Obsidian Oil.  I polished the stem with micromesh sanding pads – wetsanding it with 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I polished it with Before & After Pipe Polish – both Fine and Extra Fine and gave it a final coat and set it aside to dry.

I polished the stem with micromesh sanding pads – wetsanding it with 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I polished it with Before & After Pipe Polish – both Fine and Extra Fine and gave it a final coat and set it aside to dry.

This is the part of the restoration process that I really look forward to! When all the parts are finished and the pipe I clean then I put the stem and bowl back together and buff the pipe with Blue Diamond on the buffing wheel. I polish the briar and any minute scratches still in the vulcanite of the stem until there is a rich shine. This National Washington, D.C. pipe is a classic English looking bent billiard shape with a natural finish that highlights some amazing straight and flame grain on a proportionally well carved pipe. Buffing the pipe made the briar come alive and the grain popped with polishing. The black vulcanite stem had a rich glow. The finished pipe is a beautifully grained English Made National Bent Billiard. The pipe feels really good in the hand and sits right in the mouth. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 1/4 inches, Chamber diameter: ¾ of an inch. Thanks for walking through the restoration with me as it was a pleasure to work on.

This is the part of the restoration process that I really look forward to! When all the parts are finished and the pipe I clean then I put the stem and bowl back together and buff the pipe with Blue Diamond on the buffing wheel. I polish the briar and any minute scratches still in the vulcanite of the stem until there is a rich shine. This National Washington, D.C. pipe is a classic English looking bent billiard shape with a natural finish that highlights some amazing straight and flame grain on a proportionally well carved pipe. Buffing the pipe made the briar come alive and the grain popped with polishing. The black vulcanite stem had a rich glow. The finished pipe is a beautifully grained English Made National Bent Billiard. The pipe feels really good in the hand and sits right in the mouth. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 1/4 inches, Chamber diameter: ¾ of an inch. Thanks for walking through the restoration with me as it was a pleasure to work on.