Blog by Steve Laug

This is one big pipe. I got it in a group of pipes I bought on EBay. The others in the lot were Barlings and Bewlays. They were normal group 3 and 4 sized pipes. This one is just over 7 inches long and 2 inches tall. The outer diameter of the bowl is 1 ¾ inches and the inner diameter of the bowl is 1 inch. It presented some interesting issues that would need to be addressed in the refurbishing process. The biggest of those was a significant cigarette burn on the outer edge and the top of the rim. It was quite deep and was an actually divot in the surface of the bowl. The rim – inner edge toward the stem also was charred and tarred. The finish was actually worn and had lost most of the stain. There were some very obvious pink putty fills on the right side of the bowl near the bottom and on the top of the shank near the stem. The stem was oxidized and there was a bit of tooth chatter.

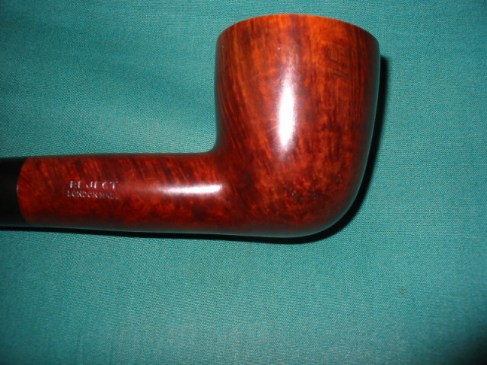

I have taken a picture of the pipe with a group 4 sized billiard to give an idea of the massive size of this old beauty. It is stamped on the left side of the shank “Made By Hand” and on the right side of the shank ‘Reject” over “London Made”. I am pretty sure that it is a Charatan reject though I cannot be certain. What do you all think? Who is the maker? The only thing making this a reject are the few fills as it has some pretty decent grain all the way around.

After I reamed and cleaned the pipe inside with isopropyl alcohol I decided to address the cigarette burn on the top and side of the rim. The only way to remove it was to top the pipe. The next series of four photos show the emery cloth attached to a cutting board so that I could work on the topping procedure. The first photo shows the angle of attack that I use on the bowl. I place it flat on the cloth and work it in circles on the paper. I keep the bowl rim flat on the paper to ensure that the surface does not become angled or slanted. The next three photos show the top after sanding. Each photo is sequential so that you can see the progress in removing the divot. The second photo below shows the side shot of the damage and you can see the depth of the burn. The next two show the gradual removal of the burn and the flattening out of the surface of the rim.

When I finished with the emery cloth I used 240 grit sandpaper to smooth out the surface and remove scratches left by the emery cloth. I used the same circular motion to sand the rim. I find that the circular motion leaves fewer scratches and also keeps the bowl flat as I work on it. The next series of three photos show the rim and side after sanding with the 240 grit sandpaper. The burn mark is now flattened out and the edge of the rim is smooth. The divot is gone. The decision I had to make at this point was whether to continue sanding to remove all of the darkening on the bowl rim or to use stains to hide it a bit and keep the profile at its current height. I opted to use the stains on the burn mark and leave it at this point. Once I had the bowl rim at this point I proceeded to use 400 and 600 grit wet dry sandpaper and then micromesh from 1500-6000 grit to smooth out the surface of the rim.

From there I decided to work on the fills. The pink putty just does not work for me. It does not take stain and it is always glaringly present in the finished pipe. The next two photos show the fills on the right side toward the bottom of the bowl and on the shank near the stem.

I wiped the bowl down with acetone (fingernail polish remover) to get the stain and finish removed. Then I used the dental pick to remove the fills. The next five photos show the opening up of the pits that were under the fills. I use the sharp point of the dental pick to pick away all of the putty and leave the holes open and free of debris. I also wipe the bowl down with acetone before filling them with the new patch.

After wiping down the surface of the pipe and cleaning out any remaining debris in the pits or holes I filled the holes with briar dust that I had saved from sanding the rim. I packed the dust into the hole with the dental pick. I find that if I wet the end of the pick the briar dust clumps on the pick. I scrape it over the holes and then tamp them full with the briar dust. I purposely over fill them with the dust. Then I drip super glue onto the briar dust patch. In the three photos below you can see the patches after the initial sanding with a fine grit pink sanding pad. They are the dark spots on the right side of the photo and on the shank near the stem. These dark spots lessen with more sanding. The second photo also shows the state of the rim from the top shot.

I heated the bowl so that I could do the contrast staining to highlight the grain. I used an artist’s brush to apply black aniline stain to the bowl. I follow the lines of the grain. I painted the bowl, shank and rim with the black stain. Then I lit it with a lighter to flame the stain and set it. Once it was dry I sanded the stain to remove the excess.

The next series of four photos show the bowl after the initial sanding. I had removed much of the stain. The reason I am showing these photos is to highlight how the fill on the side of the bowl and on the shank have faded into the finish of the pipe. The black stain not only highlights the grain but also blends in the fills with the contrast stain on the bowl. In the second and third photo I also wanted to show how the stain takes care of the burn mark on the bowl side and rim. It is still present in terms of the darkening but it is less visible at this point. That is what I was aiming for. From this point I took the pipe to my buffer and used Tripoli and White Diamond to buff out a bit more of the black so that it would highlight the grain but not be the overwhelmingly dark coat under the finish stain that I would later use. I also used micromesh pads from 3200 to 6000 grit to work out any of the remaining scratches on the rim and bowl surfaces.

At this point I set the bowl aside and went to work on the stem. In the picture below you can see the variety of micromesh pads that I use to remove the oxidation. The brown dust on the pads is the oxidation that comes off with the sanding. I always have a bowl of water at the side of the table to dip the pads in and wash off the oxidation dust and grime and also to give the pads more bite when I am sanding the stem. I went back and forth through the pads and the buffer with Tripoli and White Diamond to bring the stem back to the rich black that it had originally. I always buff the stem with it back on the pipe. I do not want to risk rounding the edge at the point where it sits against the shank. Once it was shiny black and acceptable I took the pipe back to the work table to give it the final stain coat.

For a top coat of stain I chose oxblood coloured aniline stain. I find that the contrast between it and the black undercoat work well together. The next series of four photos show the finished pipe. The first shows the left side and what remains of the burn mark near the top of the rim. It is still present but certainly less visible and it is smooth to touch. The second photo shows the right side of the pipe and how well the stain has hidden the reworked fills on the shank and near the bottom of the bowl. If you did not know they were present you would have a hard time seeing them. The third photo shows the rim and how well the stain has hidden the burn mark and brought out the birdseye grain on the rim. The final photo shows the bottom of the bowl and is included to show the contrast stain and the graining on that part of the bowl.

The next series of photos show closer views of the repairs that were down and how they blend in with the contrast stain. The first is the left side of the bowl and you can see the darkening of the rim where the burn mark was. It is smooth to touch and none of the profile of the pipe is affected. The second photo shows the part of the bowl where I removed the putty fills, refilled them with briar dust and superglue and then restained with the two coats of contrasting stain. The third photo shows the same repairs on the shank. The final photo is of the rim of the bowl. The birdseye grain is highlighted. In the slight glare at the top of the photo you can see the remaining mark from the burn. The black and oxblood stains minimize the visibility of the burn darkening. I finished the pipe by giving the entirety several coats of carnauba wax to give it a rich glow. The pipe is finished and ready to give many years of service to whoever becomes the next owner.