Blog by Steve Laug

A while back I received a small box of pipes from a fellow pipeman who wanted to donate them to support the non-profit organization I work for – the SA Foundation (www.safoundation.com). The organization has been providing long term recovery, housing and job training for women who have escaped sexual exploitation and trafficking. For over thirty years the work has gone on and thousands of young women and their children have been empowered to start over with skills and options. The work is currently in 7 countries and 12 cities around the world. If you are interested give the website a look.

Now back to the pipes. There were eight total pipes in the lot that he sent me. The first one I restored was a large Irish Second 05 Calabash that is heading off to Michigan. The second pipe was a Peterson’s Kapet pipe in a shape 124 (https://rebornpipes.com/2021/08/16/restoring-a-republic-era-petersons-kapet-124/). The third pipe was a very Danish looking Made in London, England Sandblast Acorn. (https://rebornpipes.com/2021/08/17/restoring-a-very-danish-looking-made-in-london-england-acorn/). The fourth pipe was a Bromma Bent Billiard with a screw on bowl (https://rebornpipes.com/2021/08/18/restoring-what-looks-like-a-swedish-bromma-pipe/). The fifth pipe is a Canadian Made Paradis Pipe (https://rebornpipes.com/2021/08/19/restoring-canadian-made-paradis-rustic-246-bent-dublin/). The sixth pipe was an unsmoked small carved figural meerschaum that is for sale on the rebornpipes store (https://rebornpipes.com/rebornpipes-store/meerschaum-pipes-smooth-figurals/). All of the pipes were in clean condition and had been lightly reamed.

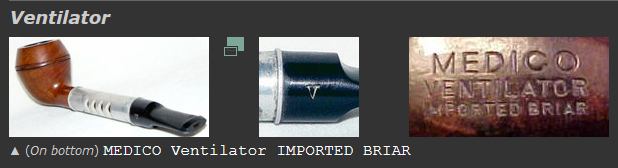

The next pipe, the seventh one is a bent Medico Ventilator with an aluminum slotted, ventilated shank. The pipe was clean on the inside but dusty on the sandblast finish. The sandblast was very well done and quite rugged. The rim top and edges looked very good. I think that this pipe was not smoked very much. The pipe was stamped on the flat heel of the bowl and read Medico [over] Ventilator [over] Imported Briar. The aluminum shank was dull looking but otherwise in great condition. The short bent saddle stem had a lot of tooth chatter and marks on both sides ahead of the button. There was a V logo stamped on the left side of the stem. The aluminum tenon was made to hold the classic Medico paper filter. I took some photos of the pipe before I started my clean up work on it.

I took photos of the bowl and rim top as well as the stem to show the condition of the pipe. The rim top was dusty and worn looking but it was otherwise clean. The bowl was slightly misshapen like I have seen before on these Ventilator pipe. It is not quite round with the thicker edges on the front of the bowl and narrower on the sides and rear of the bowl. The stem had a lot of tooth chatter and some deep tooth marks on both the top and bottom.

I took photos of the bowl and rim top as well as the stem to show the condition of the pipe. The rim top was dusty and worn looking but it was otherwise clean. The bowl was slightly misshapen like I have seen before on these Ventilator pipe. It is not quite round with the thicker edges on the front of the bowl and narrower on the sides and rear of the bowl. The stem had a lot of tooth chatter and some deep tooth marks on both the top and bottom.  I took a photo of the stamping on the underside of the heel of the bowl. It was clear and readable as noted above.

I took a photo of the stamping on the underside of the heel of the bowl. It was clear and readable as noted above.  I removed the stem from the shank and took a photo of the pipe. The great sandblast and the unique design of the Ventilator is visible in the photo.

I removed the stem from the shank and took a photo of the pipe. The great sandblast and the unique design of the Ventilator is visible in the photo.  I turned to Pipephil’s site for a quick summary (http://pipephil.eu/logos/en/logo-medico.html). I have included a screen capture of the information on the site.

I turned to Pipephil’s site for a quick summary (http://pipephil.eu/logos/en/logo-medico.html). I have included a screen capture of the information on the site. I also quote the information from the side bar of the entry on pipephil:

I also quote the information from the side bar of the entry on pipephil:

This model cannot be smoked without the use of the rolled paper filters.Others metal pipes logos & markings in these pages: Alco, Bryson, Duncan, Falcon, Kaywoodie (Filter Pipe , Filter plus, Filtronic), Ornsby

I turned to Pipedia for more info (https://pipedia.org/wiki/Medico). There was a brief writeup on the history of the brand and the paper filtration system but nothing specific on the Ventilator pipes.

Now it was time to work on the pipe. I started my work on the pipe by scrubbing the bowl and shank exterior with undiluted Murphy’s Oil Soap. I scrubbed the sandblast and the aluminum with a tooth brush and the soap and rinsed it off with running water. I dried it off with a cotton towel.

I touched up the stain on the rim top with a Walnut Stain Pen. It matched the rest of the bowl colour perfectly.

I touched up the stain on the rim top with a Walnut Stain Pen. It matched the rest of the bowl colour perfectly. I cleaned the mortise/and aluminum shank along with the airway in both the shank and the stem with 99% isopropyl alcohol, pipe cleaners and cotton swabs until the interior of the pipe was very clean.

I cleaned the mortise/and aluminum shank along with the airway in both the shank and the stem with 99% isopropyl alcohol, pipe cleaners and cotton swabs until the interior of the pipe was very clean. I rubbed the bowl and the briar portion of shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for ten minutes then buffed the bowl with a cotton cloth to raise the shine.

I rubbed the bowl and the briar portion of shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for ten minutes then buffed the bowl with a cotton cloth to raise the shine.

I polished the aluminum ventilated shank with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped it down with a clean paper towel after each sanding pad. The aluminum took on a rich shine with the polishing.

I polished the aluminum ventilated shank with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped it down with a clean paper towel after each sanding pad. The aluminum took on a rich shine with the polishing.

I set the bowl aside and turned my attention to the stem. There was a plastic/hard clear rubber insert that fit in the aluminum ventilated shank to hold the stem tightly in place. When I removed the stem the insert came out as well and was stuck on the aluminum tenon of the stem. I carefully used a pair of vise grips to hold the rubber insert and slowly turned the stem until I was able to remove it. Once the aluminum shank was cleaned I would glue it in place in the shank so that it would stay in place there.

I set the bowl aside and turned my attention to the stem. There was a plastic/hard clear rubber insert that fit in the aluminum ventilated shank to hold the stem tightly in place. When I removed the stem the insert came out as well and was stuck on the aluminum tenon of the stem. I carefully used a pair of vise grips to hold the rubber insert and slowly turned the stem until I was able to remove it. Once the aluminum shank was cleaned I would glue it in place in the shank so that it would stay in place there. I coated the outside of the hard rubber/acrylic ring with white all-purpose glue and pushed it into place in the aluminum ventilator shank. I removed the stem and set the bowl and shank aside for the glue to cure.

I coated the outside of the hard rubber/acrylic ring with white all-purpose glue and pushed it into place in the aluminum ventilator shank. I removed the stem and set the bowl and shank aside for the glue to cure. I “painted” the tooth marks and chatter on the stem surface with the flame of a lighter to try and raise the dents. The stem is a typical Medico stem which seems to be a mix of vulcanite and plastic or nylon so the flame did very little. I filled the tooth chatter and marks in with clear CA glue and set it aside to cure. Once it cured I used a small file to flatten out the repairs and reshape the button edge. I used 220 grit sandpaper to smooth out the repairs on both sides of the stem. I started to polish it with 400 grit wet dry sandpaper. The stem is looking much better.

I “painted” the tooth marks and chatter on the stem surface with the flame of a lighter to try and raise the dents. The stem is a typical Medico stem which seems to be a mix of vulcanite and plastic or nylon so the flame did very little. I filled the tooth chatter and marks in with clear CA glue and set it aside to cure. Once it cured I used a small file to flatten out the repairs and reshape the button edge. I used 220 grit sandpaper to smooth out the repairs on both sides of the stem. I started to polish it with 400 grit wet dry sandpaper. The stem is looking much better.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it a final rubdown with Obsidian Oil and set it aside to cure.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it a final rubdown with Obsidian Oil and set it aside to cure.

I fitted the stem and shank with a Medico paper filter. It fit in the tenon and in the aluminum shank. All air flow from the bowl came through the filter and the cool air came in through the aluminum ventilator shank. The theory is it provided a cool smoke – mind you soggy but cool!

I fitted the stem and shank with a Medico paper filter. It fit in the tenon and in the aluminum shank. All air flow from the bowl came through the filter and the cool air came in through the aluminum ventilator shank. The theory is it provided a cool smoke – mind you soggy but cool! I put the parts back together. This Medico Ventilator Imported Briar Bent Billiard is a great looking pipe with a great sandblast on the bowl. The rich, dark brown stained sandblast bowl and the ventilated polished aluminum shank look surprisingly nice. The combination works well with the polished saddle stem. I carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Medico Ventilator Bent Billiard is light and sits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 44 grams/1.52 ounces. I will be putting it on the rebornpipes store shortly in the American (US) Pipemakers Section. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

I put the parts back together. This Medico Ventilator Imported Briar Bent Billiard is a great looking pipe with a great sandblast on the bowl. The rich, dark brown stained sandblast bowl and the ventilated polished aluminum shank look surprisingly nice. The combination works well with the polished saddle stem. I carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Medico Ventilator Bent Billiard is light and sits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 44 grams/1.52 ounces. I will be putting it on the rebornpipes store shortly in the American (US) Pipemakers Section. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!