Blog by Steve Laug

Earlier in June I received an email regarding restoring some pipes for her husband. Here is here email.

I have one Calich and one Dunhill pipe which my husband destroyed using a torch lighter on. I am wondering if it is possible to get them restored somehow. If you want to have a look I can send pics.

I wrote and asked for photos of the pipes. She wrote that there were actually 5 pipes not two and included photos of all five. I asked her if she was wanting to sell them or just repair them. Here is her response.

No… I don’t want to sell (yet) he’s 86 and has taken up smoking his pipes again. He was using a torch lighter until I discovered and replaced with proper pipe lighters. For now I’m wondering if it’s possible or even wise to restore them. – Kathleen.

I replied to Kathleen and invited her to send the pipes to me in Vancouver. They arrived just before I left for my visit with my Dad in Idaho. Here is what I found when they arrived. There were three Caliches, a Dunhill, and an Ed Burak Connoisseur. The Calich Pipes included a rusticated straight Opera, a bent Rhodesian with an octagonal rim cap and an acrylic stem. The Dunhill was a sandblast Billiard with a repair band on the shank. The Ed Burak Connoisseur was a bent Bulldog. All had rim top damage from being lit with a torch lighter. Some were in worse condition than others. The worst were the Calich Opera and the Dunhill Billiard which had torch damage on the left side of the rim and down the bowl side. The others had varying degrees of burn damage. I set them aside until I returned home from my visit. She sent me photos of the next pipe, a Calich Opera Pipe.

I took the pipes out of the box and laid the group out on my worktable. I took some photos of the group to show their condition. The photo of the left side of the shank shows the damage I mentioned in the earlier paragraphs. The right-side photo looks very good. The photos from the rim top show a lot of damage and the overall condition of the pipes very clear.

I took the pipes out of the box and laid the group out on my worktable. I took some photos of the group to show their condition. The photo of the left side of the shank shows the damage I mentioned in the earlier paragraphs. The right-side photo looks very good. The photos from the rim top show a lot of damage and the overall condition of the pipes very clear.

After looking through the last two pipes I decided to work on the last of the Calich pipes and by far the one with the worst damage of the three. This one is a rusticated oval bowled pipe or Opera that is stamped CALICH [over] Hand Made [over] 8 and above that 86. It had a smooth rim top, shank end and a rectangle on the underside for the stamping. The pipe had a very thick cake in the bowl and there was a lava overflow on the top. There was also a ball of unburned tobacco in the bottom half of the bowl. There was some major burn damage under the lava on the front edge of the bowl toward the front right as well as a deep burned area on the left back side and edge. The burn was like a large bite out of the top and left side of the bowl as can be seen in the photos. The shank had a thick coat of tars and oils and the stem had a thick tar build up as well so its fit in the shank was very sticky and dirty. The stem itself is vulcanite with a single silver dot on the topside. It was oxidized and had light tooth marks and chatter on both sides of the stem just ahead of the button. There were overflowing tars on the smooth shank end around the fit of the tenon in the mortise. The finish was dusty and tired but had a nice rustication under the grime and appeared to be in good condition. A lot would be revealed once I had cleaned it. I took photos of the pipe before I started my cleanup work.

After looking through the last two pipes I decided to work on the last of the Calich pipes and by far the one with the worst damage of the three. This one is a rusticated oval bowled pipe or Opera that is stamped CALICH [over] Hand Made [over] 8 and above that 86. It had a smooth rim top, shank end and a rectangle on the underside for the stamping. The pipe had a very thick cake in the bowl and there was a lava overflow on the top. There was also a ball of unburned tobacco in the bottom half of the bowl. There was some major burn damage under the lava on the front edge of the bowl toward the front right as well as a deep burned area on the left back side and edge. The burn was like a large bite out of the top and left side of the bowl as can be seen in the photos. The shank had a thick coat of tars and oils and the stem had a thick tar build up as well so its fit in the shank was very sticky and dirty. The stem itself is vulcanite with a single silver dot on the topside. It was oxidized and had light tooth marks and chatter on both sides of the stem just ahead of the button. There were overflowing tars on the smooth shank end around the fit of the tenon in the mortise. The finish was dusty and tired but had a nice rustication under the grime and appeared to be in good condition. A lot would be revealed once I had cleaned it. I took photos of the pipe before I started my cleanup work.

I took a close-up photo of the bowl and rim top to show its condition. The inside of the bowl was heavily caked with a wet oily tobacco and a ball of tobacco in the bottom half. The rim top had damage on the front right in the photo below as well as on the back left. The back left side is the worst as it is quite thin and is like a deep bite mark down the side of the bowl. It left a mess for me to clean up. The stem was also is a mess. There was some light tooth marks and chatter on the top and underside ahead of the button. There was a thick coat of calcification and oxidation on the stem. The silver dot on the stem top was tarnished but very visible.

I took a close-up photo of the bowl and rim top to show its condition. The inside of the bowl was heavily caked with a wet oily tobacco and a ball of tobacco in the bottom half. The rim top had damage on the front right in the photo below as well as on the back left. The back left side is the worst as it is quite thin and is like a deep bite mark down the side of the bowl. It left a mess for me to clean up. The stem was also is a mess. There was some light tooth marks and chatter on the top and underside ahead of the button. There was a thick coat of calcification and oxidation on the stem. The silver dot on the stem top was tarnished but very visible. I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above. I removed the stem from the shank and took a photo of the silver dot on the stem top.

I took a photo of the stamping on the underside of the shank. It is clear and readable as noted above. I removed the stem from the shank and took a photo of the silver dot on the stem top.  I am once again including information about John Calich the pipemaker as I have loved John Calich’s pipes for over 25 years now and have collected a few of them. I have restored quite a few of them and written blogs about them that can be read if you are interested in seeing the kind of pipes that John made. They are unique and beautiful. Each of his pipes are a work of art to me. I am including the links to the previous blogs that have written about his pipes.

I am once again including information about John Calich the pipemaker as I have loved John Calich’s pipes for over 25 years now and have collected a few of them. I have restored quite a few of them and written blogs about them that can be read if you are interested in seeing the kind of pipes that John made. They are unique and beautiful. Each of his pipes are a work of art to me. I am including the links to the previous blogs that have written about his pipes.

https://rebornpipes.com/2015/03/03/one-of-my-john-calich-pipes-a-calich-ee-billiard/

https://rebornpipes.com/2019/01/23/i-am-the-happy-owner-of-an-unsmoked-pipe-by-the-late-john-calich/

https://rebornpipes.com/2015/03/03/one-of-my-john-calich-pipes-a-calich-ee-billiard/

https://rebornpipes.com/2014/03/21/reflecting-on-my-collection-of-john-calich-pipes/

Each of the blogs reflects on John’s pipes if you want to get a feel for them take a few minutes and read them.

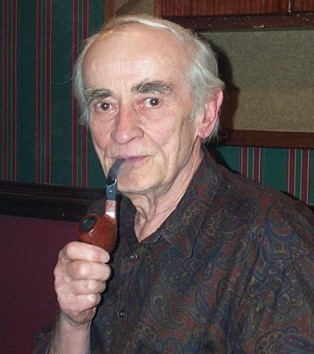

When John was living I spoke with him several times via phone and had him make some new stems for some of his pipes that I picked up off eBay. He was a very kind gentleman and was always helpful when I spoke with him. He was always ready with encouragement and when I needed to know how to do something when I was first learning to repair pipes he was willing to help. He was one of the old guard of Canadian Pipe makers. I miss him. I am including a short piece from Pipedia on John to give details on his work and the grading of his pipes. The second paragraph below is highlighted in blue as it gives some information on the Grade 12 Apple that I am working on with the single silver dot now. I am also including a photo of John Calich, courtesy Doug Valitchka

John Calich was one of Canada’s finest carvers. He died in July 2008. John was a full-time pipe maker for the last 40 years. Calich pipes were mostly traditional shapes. His signature style is rustication and smooth on the same pipe along with his unique skill to stain a pipe in contrasting colors. He used only top-quality Grecian and Calabrian briar. The mouthpieces are hand finished Vulcanite “A”. Each pipe was entirely made by hand. John Calich was featured in the summer 2005 issue of Pipes & Tobacco.

John Calich was one of Canada’s finest carvers. He died in July 2008. John was a full-time pipe maker for the last 40 years. Calich pipes were mostly traditional shapes. His signature style is rustication and smooth on the same pipe along with his unique skill to stain a pipe in contrasting colors. He used only top-quality Grecian and Calabrian briar. The mouthpieces are hand finished Vulcanite “A”. Each pipe was entirely made by hand. John Calich was featured in the summer 2005 issue of Pipes & Tobacco.

His pipes are graded 3E – 7E. Retail prices range from$ 145.00 to $ 500.00 Each pipe is stamped “CALICH” 3-8E, his earlier pipes were graded from 3-14, and a single, tiny silver dot is applied to the top of the stem (https://pipedia.org/wiki/Calich).

I summarize the dating information from those blogs now: From my research and conversations I learned that John’s later pipes were graded 3E – 8E. The retail prices for them ranged from $145.00 to $500.00. Each pipe was stamped “CALICH” and given an E grade. His earlier pipes were graded from 3-14 and had a single, tiny silver dot applied to the top of the stem. More information can be found at the Pipedia article above. All of this information told me as expected that the pipe I had was an earlier one.

Armed with the information about John’s grading system I knew that the pipe in hand was an earlier Calich Hand Made Grade 8 Opera pipe and the 86 told me it was made in 1986. Now it was time to work on the pipe. The PipNet reamer would not fit in the bowl so I reamed the oval bowl with a Savinelli Fitsall Pipe Knife to scrape back the remaining cake. I would finish my cleaning of the bowl later by sanding it by hand.  Once it was clean I turned my attention to the rim top. I cleaned up the inner edge of the bowl with a folded piece of 220 grit sandpaper. I flattened out the damaged area with the sandpaper to give a flat surface for my repair. I topped the bowl with 220 grit sandpaper on a topping board to give the rim top a smooth surface.

Once it was clean I turned my attention to the rim top. I cleaned up the inner edge of the bowl with a folded piece of 220 grit sandpaper. I flattened out the damaged area with the sandpaper to give a flat surface for my repair. I topped the bowl with 220 grit sandpaper on a topping board to give the rim top a smooth surface.

I decided to work on the repair to the deep burned area on the left side of the bowl. I cut a piece of briar out of a cracked bowl I keep around for just this purpose. I eyeballed the shape of the divot and used a hacksaw blade and a carving knife to remove the chunk that I would use. I shaped the piece of briar more closely to the shape with a Dremel and a sanding drum.

I decided to work on the repair to the deep burned area on the left side of the bowl. I cut a piece of briar out of a cracked bowl I keep around for just this purpose. I eyeballed the shape of the divot and used a hacksaw blade and a carving knife to remove the chunk that I would use. I shaped the piece of briar more closely to the shape with a Dremel and a sanding drum.

I mixed up a batch of JB Weld and applied the mixture with a dental spatula to the divot on the bowl side and on the underside of the cut piece of briar. I pressed the piece of briar into divot on the bowl side. I held it until it started to set and then set it aside to cure. I purposely used a little taller piece of briar than necessary as it gave me material to work with. I have found it simpler to work with the larger piece and then remove the excess. Once the JB Weld set enough for the repair not to move I set it aside to cure.

I mixed up a batch of JB Weld and applied the mixture with a dental spatula to the divot on the bowl side and on the underside of the cut piece of briar. I pressed the piece of briar into divot on the bowl side. I held it until it started to set and then set it aside to cure. I purposely used a little taller piece of briar than necessary as it gave me material to work with. I have found it simpler to work with the larger piece and then remove the excess. Once the JB Weld set enough for the repair not to move I set it aside to cure.

Once the piece was solid in the repair I decided to work on the internals. I scraped the inside of the mortise with a dental spatula to remove the hardened tars and oils that lined the walls of the shank. Once I had that done I cleaned out the airway to the bowl, the mortise and the airway in the stem with pipe cleaners, cotton swabs and alcohol. When I finished the pipe smelled very clean.

Once the piece was solid in the repair I decided to work on the internals. I scraped the inside of the mortise with a dental spatula to remove the hardened tars and oils that lined the walls of the shank. Once I had that done I cleaned out the airway to the bowl, the mortise and the airway in the stem with pipe cleaners, cotton swabs and alcohol. When I finished the pipe smelled very clean.

Once the repair had cured I used a Dremel and sanding drum to remove the excess briar and flatten out the rim top as much as possible with the tool. I then topped the bowl again on a topping board with 220 grit sandpaper to get a smooth rim top.

Once the repair had cured I used a Dremel and sanding drum to remove the excess briar and flatten out the rim top as much as possible with the tool. I then topped the bowl again on a topping board with 220 grit sandpaper to get a smooth rim top.

With the top flattened, I used files to reduce the inner edge and reshape it to match the inner edge on the right side of the bowl. It took a bit of time and working through several needle files but it looked much better when I finished. I still had some work to do on the rim top and the inner edge but it was very close. I am still trying to decide if I will leave the rim top smooth or rusticate it to match the bowl rustication. Time will tell!

With the top flattened, I used files to reduce the inner edge and reshape it to match the inner edge on the right side of the bowl. It took a bit of time and working through several needle files but it looked much better when I finished. I still had some work to do on the rim top and the inner edge but it was very close. I am still trying to decide if I will leave the rim top smooth or rusticate it to match the bowl rustication. Time will tell!

I mixed up another batch of the JB Weld and spread it on to the inside wall of the bowl to protect the area where the bowl and inserted piece joined. This would keep the heat from following the repair joint out to the exterior and create potential burnout in the bowl. I set it aside to allow the JB Weld time to cure and harden before I sanded it smooth.

I mixed up another batch of the JB Weld and spread it on to the inside wall of the bowl to protect the area where the bowl and inserted piece joined. This would keep the heat from following the repair joint out to the exterior and create potential burnout in the bowl. I set it aside to allow the JB Weld time to cure and harden before I sanded it smooth. I scrubbed the briar with some Before & After Briar Cleaner and a tooth brush and wiped it off with a clean paper towel. The Briar Cleaner removed a lot of built up grime and oils from the grooves of the rustication and the bowl looked much better.

I scrubbed the briar with some Before & After Briar Cleaner and a tooth brush and wiped it off with a clean paper towel. The Briar Cleaner removed a lot of built up grime and oils from the grooves of the rustication and the bowl looked much better.

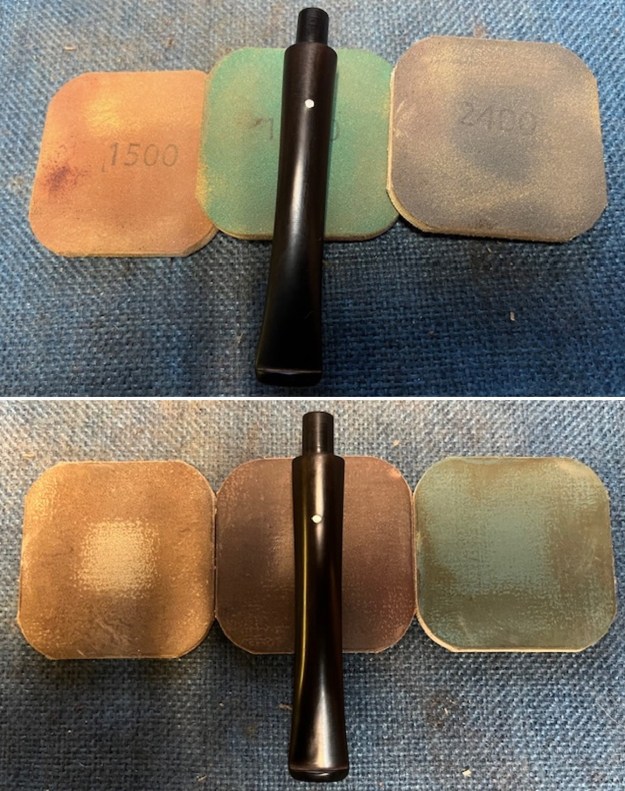

I polished the smooth rim top with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each pad. I was able to smooth it out nicely and it did not look too bad. The repaired area actually blended in very well. I would not need to rusticated it! I touched up the sanded and rebuilt rim top with a Cherry stain pen. The match on the rim with the rest of the pipe is perfect.

I polished the smooth rim top with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each pad. I was able to smooth it out nicely and it did not look too bad. The repaired area actually blended in very well. I would not need to rusticated it! I touched up the sanded and rebuilt rim top with a Cherry stain pen. The match on the rim with the rest of the pipe is perfect. Once the internal coating of JB Weld cured I sanded it with 220 grit sandpaper to smooth it out. I then mixed a batch of bowl coating with some sour cream and charcoal powder and coated the walls of the entire bowl. I used two teaspoons of sour cream and four of the Charco caps to mix a black/grey mixture that I use for the bowl coating. I applied it to the walls of the bowl with a folded pipe cleaner and covered the interior of the bowl with it so that it was smooth. I set it aside to cure. Once it hardens and dries it is odorless and leaves behind no lingering taste.

Once the internal coating of JB Weld cured I sanded it with 220 grit sandpaper to smooth it out. I then mixed a batch of bowl coating with some sour cream and charcoal powder and coated the walls of the entire bowl. I used two teaspoons of sour cream and four of the Charco caps to mix a black/grey mixture that I use for the bowl coating. I applied it to the walls of the bowl with a folded pipe cleaner and covered the interior of the bowl with it so that it was smooth. I set it aside to cure. Once it hardens and dries it is odorless and leaves behind no lingering taste.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for ten minutes then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for ten minutes then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I set the bowl aside and turned my attention to the stem. I “painted” the stem surface of the stem with the flame of a Bic lighter to lift the tooth marks and chatter on the surface. I was able to remove it all. I sanded the stem surface with 220 grit sandpaper to remove the remaining chatter marks. I wiped the stem down with an Obsidian Oil cloth and it looked much better at this point.

I set the bowl aside and turned my attention to the stem. I “painted” the stem surface of the stem with the flame of a Bic lighter to lift the tooth marks and chatter on the surface. I was able to remove it all. I sanded the stem surface with 220 grit sandpaper to remove the remaining chatter marks. I wiped the stem down with an Obsidian Oil cloth and it looked much better at this point. I sanded the stem with 320-3500 grit sanding pads to break up the remaining oxidation. I wiped it down after each sanding pad with a soft cloth. It began to look good.

I sanded the stem with 320-3500 grit sanding pads to break up the remaining oxidation. I wiped it down after each sanding pad with a soft cloth. It began to look good.  I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of Obsidian Oil and set it aside to dry.

This is the fourth of five pipes from Kathleen that I am working on. It is another beautifully shaped 1986 John Calich Hand Made Grade 8 Opera Pipe. It has the kind of beauty I have come to expect from John’s pipes with a smooth rim top and shank end. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rusticated finish is well done and the polished smooth finish on the shank end and rim top look really good with the black vulcanite stem. This Calich Hand Made Opera Pipe was a challenging pipe to bring back to life. It is a comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1inch x 1 ¼ inches, Chamber diameter: 7/8 of an inch x ½ of an inch. The weight of the pipe is 27 grams/.95 ounces. Thanks for reading this blog and my reflections on the pipe while I worked on it. Once I finish the last pipe in the lot I will be sending them back to Kathleen for her husband to enjoy.

This is the fourth of five pipes from Kathleen that I am working on. It is another beautifully shaped 1986 John Calich Hand Made Grade 8 Opera Pipe. It has the kind of beauty I have come to expect from John’s pipes with a smooth rim top and shank end. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rusticated finish is well done and the polished smooth finish on the shank end and rim top look really good with the black vulcanite stem. This Calich Hand Made Opera Pipe was a challenging pipe to bring back to life. It is a comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ¾ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1inch x 1 ¼ inches, Chamber diameter: 7/8 of an inch x ½ of an inch. The weight of the pipe is 27 grams/.95 ounces. Thanks for reading this blog and my reflections on the pipe while I worked on it. Once I finish the last pipe in the lot I will be sending them back to Kathleen for her husband to enjoy.