Blog by Steve Laug

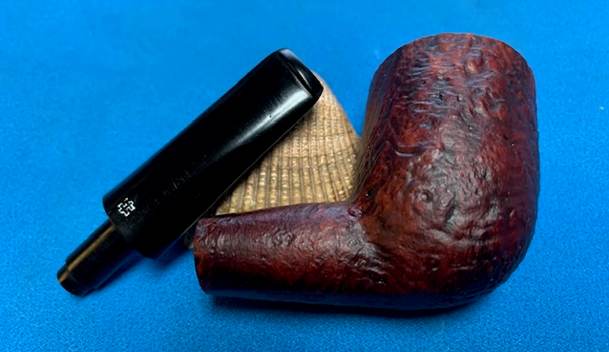

The next pipe I have chosen to work on is a nice looking sandblast taper to oval shank Nosewarmer Billiard with a taper vulcanite stem. We picked it up on 11/14/2022 from a seller in Copenhagen, Denmark. The stamping on the underside of the shank read S2 on the heel of the bowl. That is followed by HILSON [over] Stronghold. The black vulcanite oval taper stem has a Hilson H logo stamp on the topside of the stem. The pipe is a nice looking pipe with medium and dark brown finish that gives depth to the blast on the bowl sides and shank. It is light weight and comfortable pipe to hold. Jeff sent me the following photos of the pipe to show the condition it was in before he worked on it.

This is what I saw when I looked over the pipe.

- The finish on the bowl and shank has some oils darkening the side from the smoker’s hands. There is also some grime ground into sandblast nooks and crannies around the bowl and shank. The stain is dull and the grain patterns in the blast though visible under the grime are obscured around the bowl sides and shank

- The rim top was very dirty with a heavy lava coat on it. It is heavier on the front right and backside. The inner edge of the bowl is hard to see under the thick build up of cake that has overflown the bowl top.

- There was a thick cake in the bowl. The bowl itself was very dark and dirty. Once the bowl was cleaned up we could confirm the condition of the bowl walls.

- The vulcanite stem was filthy, oxidized, calcified and had tooth marks and chatter on both sides.

- There is a Hilson H logo stamped on the topside of the stem. It is faint and dirty but still readable.

To summarize what I saw – this sandblast Hilson Stronghold is a well made and uniquely shaped pipe. The bowl and stem are very dirty which says to me that once again this pipe was someone’s favourite pipe. The look and feel of the pipe in the hand is great. It should clean up very well. Here are photos of the pipe taken before Jeff started the clean up.  Jeff took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is thick – covering the walls of the bowl. The rim top has thick lava coat overflowing and covering the inner edge. It is heavier on the right front and toward the back of the bowl. It is hard to know the condition of the inner edge in this condition. This is what I look for when assessing a pipe. I look forward to viewing it in person after the clean up work.

Jeff took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is thick – covering the walls of the bowl. The rim top has thick lava coat overflowing and covering the inner edge. It is heavier on the right front and toward the back of the bowl. It is hard to know the condition of the inner edge in this condition. This is what I look for when assessing a pipe. I look forward to viewing it in person after the clean up work. The vulcanite taper stem is dirty, oxidized and calcified. There are light tooth marks and chatter on both sides ahead of the button. The white stamped Hilson logo is readable but worn.

The vulcanite taper stem is dirty, oxidized and calcified. There are light tooth marks and chatter on both sides ahead of the button. The white stamped Hilson logo is readable but worn.

Instead of telling you what I see in the next photos of the sides of the bowl and the heel I want to hear from you. Tell me what you see? What does the finish look like to you? Are there any visible problems or issues that stand out to you? Are there cracks or scratches in nooks and crannies of the sandblast finish of the bowl? Are there visible flaws or fissures in the briar? What does the finish look like? Is there a pattern to it? Any visible issues on the heel of the bowl? These questions should help you to see what I am looking for when I see these photos.

Instead of telling you what I see in the next photos of the sides of the bowl and the heel I want to hear from you. Tell me what you see? What does the finish look like to you? Are there any visible problems or issues that stand out to you? Are there cracks or scratches in nooks and crannies of the sandblast finish of the bowl? Are there visible flaws or fissures in the briar? What does the finish look like? Is there a pattern to it? Any visible issues on the heel of the bowl? These questions should help you to see what I am looking for when I see these photos.

He took photos of the stamping on the underside of the shank. It is stamped as noted above. The vulcanite stem shows a Hilson “H” stamp on the topside of the taper. What stands out for you in the photos of the stamping? What do you look for in the stamping? It is dirty but what do you see underneath the grime on the surface of the briar?

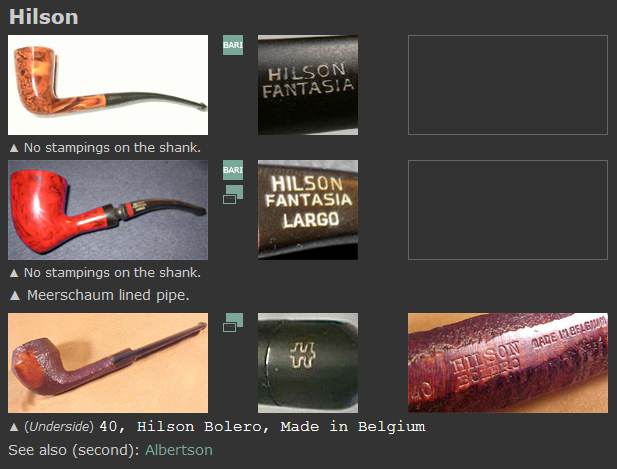

He took photos of the stamping on the underside of the shank. It is stamped as noted above. The vulcanite stem shows a Hilson “H” stamp on the topside of the taper. What stands out for you in the photos of the stamping? What do you look for in the stamping? It is dirty but what do you see underneath the grime on the surface of the briar? I turned to Pipephil’s site (http://pipephil.eu/logos/en/logo-h3.html) to look up information on the Hilson brand. It did not have any pipes stamped Stronghold. I have included the screen capture below that gives some information. I have also included the sidebar information that gives a brief history of the brand.

I turned to Pipephil’s site (http://pipephil.eu/logos/en/logo-h3.html) to look up information on the Hilson brand. It did not have any pipes stamped Stronghold. I have included the screen capture below that gives some information. I have also included the sidebar information that gives a brief history of the brand. In 1846 a German named Jean Knödgen started to produce clay pipe in Belgium. In the late 19th century Jean Hillen who married into the Knödgen family took over the company and changed the firm in order to manufacture briar pipe. Jean Hillen had 2 sons: Jos Hillen was responsible for sales and Albert Hillen was responsible for the production. After WWII Albert founded the HILSON brand (Hillen and Son) and exported his pipes all over the world.

In 1846 a German named Jean Knödgen started to produce clay pipe in Belgium. In the late 19th century Jean Hillen who married into the Knödgen family took over the company and changed the firm in order to manufacture briar pipe. Jean Hillen had 2 sons: Jos Hillen was responsible for sales and Albert Hillen was responsible for the production. After WWII Albert founded the HILSON brand (Hillen and Son) and exported his pipes all over the world.

In 1980 after having gone bankrupt, the Belgian brand from Bree (Limburg) was taken over by the Royal Dutch Pipe Factory.

I also turned to Pipedia for a bit more information (https://pipedia.org/wiki/Hilson). I am including the information I found there below.

Jean-Claude Hillen (other sources: Jean-Paul) founded a trading company in the City of Bree in 1846. He soon turned his main interest on pipes and other tobacco related goods.

Particularly in the 1960’s and still throughout the 1970’s the brand Hilson of Broers Hillen B.V. (Hillen Bros. Co.) was quite successful in many European countries. They produced large numbers of machine made pipes covering the whole range of shapes and finishes. The pipes were well respected for good quality and craftsmenship at very moderate prices.

Rarely seen there are also nice freehands from this era stamped MASTRO and signed by A.M. Sanoul, who is otherwise completely unknown as a pipemaker.

All the same, in 1980 Hillen faced major financial problems. At this time there was only a second manufacturer of briars pipes in the Benelux countries, the Elbert Gubbels & Zonen B.V. in the Netherlands. The Belgian competitor being in trouble, Gubbels used the favour of the hour and bought up the company. The reason is plausible: in some countries, particularly in Germany, Hilson held larger market shares than Gubbels’ mainstay brand Big Ben.

The Hillen plant in Bree was closed down shortly after and ever since then Hilson pipes are manufactured in Roermond, NL.

There was an advertisement in the side bar that included the same shaped pipe that I am working on. From that I found that the shape is a 510. The blast on the one I have is similar to the blast of the other pipe in the ad. The taper on the stem, the flow of the bowl and the stem is identical. Jeff did a major clean up job on this one and the pipe I received when it arrived in Vancouver looked far better than the one pictured above. Here is what I saw when I brought the pipe to the table.

Jeff did a major clean up job on this one and the pipe I received when it arrived in Vancouver looked far better than the one pictured above. Here is what I saw when I brought the pipe to the table.

- The finish is clean and the oils and grime are gone from the bowl. The finish shows the beautiful contrast in the stains in the sandblast finish around the bowl and shank. There is a portion of the stain on the right side of the bowl toward the top that is washed out and will need to be touched up.

- The rim top was clean and the top and the inner edge of the bowl look very good. There was no damage to the outer edges as well.

- There cake in the bowl has been removed and the bowl is very clean. The walls of the bowl are smooth and appear to be undamaged and show no checking or burn damage.

- The vulcanite taper stem looks better though the light tooth marks and chatter on both sides are visible.

- The Hilson H logo stamped on the topside of the stem looks very clean and readable.

Hopefully the steps above show you both what I look for when I go over the pipe when I bring it to the work table and also what I see when I look at the pipe in my hands. They also clearly spell out a restoration plan in short form. My work is clear and addressing it will be the next steps. I took photos of the whole pipe to give you a picture of what I see when I have it on the table. This is important to me in that it also shows that there was no damage done during the clean up work or the transit of the pipe from Idaho to here in Vancouver.

I carefully went over the bowl and rim top to get a sense of what is happening there. In this case once the rim top and edges were cleaned the rim top looked better. The inner edge was in good condition and looked good. I also went over the stem carefully. The fit to the shank is snug and the transitions are smooth. There were some tooth marks and chatter on the surface of the stem and the button on the underside. The vulcanite stem surface was clean and looked better. I took photos of the rim top and stem sides to show as best as I can what I see when I look at them.

I carefully went over the bowl and rim top to get a sense of what is happening there. In this case once the rim top and edges were cleaned the rim top looked better. The inner edge was in good condition and looked good. I also went over the stem carefully. The fit to the shank is snug and the transitions are smooth. There were some tooth marks and chatter on the surface of the stem and the button on the underside. The vulcanite stem surface was clean and looked better. I took photos of the rim top and stem sides to show as best as I can what I see when I look at them.  I always check to make sure that the clean up work did not damage the stamping on the shank sides in any way. It is in excellent condition and is very clear and readable. I love just looking at the lay of the pipe and the proportion of the hand made pipes. I took the pipe apart to get a sense of what was in the mind of the pipe maker when he crafted the pipe. The photo shows its beauty in flow and shape.

I always check to make sure that the clean up work did not damage the stamping on the shank sides in any way. It is in excellent condition and is very clear and readable. I love just looking at the lay of the pipe and the proportion of the hand made pipes. I took the pipe apart to get a sense of what was in the mind of the pipe maker when he crafted the pipe. The photo shows its beauty in flow and shape. I touched up the stain on the right side of the bowl with a Mahogany stain pen to blend it into the surrounding briar. I applied it and buffed it off with a clean paper towel. The look of the area matches the rest of the briar.

I touched up the stain on the right side of the bowl with a Mahogany stain pen to blend it into the surrounding briar. I applied it and buffed it off with a clean paper towel. The look of the area matches the rest of the briar. I rubbed down the bowl and shank with Before & After Restoration Balm. It is a paste/balm that is rubbed into the surface of the briar. The product works to deep clean the finish, enliven and protect the briar. I worked it into the briar with my finger tips. I let it sit for 10 minutes then wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine in the briar and the sandblast showed depth. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

I rubbed down the bowl and shank with Before & After Restoration Balm. It is a paste/balm that is rubbed into the surface of the briar. The product works to deep clean the finish, enliven and protect the briar. I worked it into the briar with my finger tips. I let it sit for 10 minutes then wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine in the briar and the sandblast showed depth. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

I set the bowl aside and turned to the stem. I touched up the faint H stamping on the topside of the stem with White Acrylic Fingernail Polish. Once it dried I scraped it off and polished that area with a 1500 grit micromesh sanding pad. It is quite readable.

I set the bowl aside and turned to the stem. I touched up the faint H stamping on the topside of the stem with White Acrylic Fingernail Polish. Once it dried I scraped it off and polished that area with a 1500 grit micromesh sanding pad. It is quite readable. I polished the stem with micromesh sanding pads – 1500-12000 grit sanding pads and water to wet sand the stem. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pads. I find it does two things – first it gives some protection to the stem from buildup and second it give the sanding pads bite in the polishing process.

I polished the stem with micromesh sanding pads – 1500-12000 grit sanding pads and water to wet sand the stem. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pads. I find it does two things – first it gives some protection to the stem from buildup and second it give the sanding pads bite in the polishing process.

After finishing with the micromesh pads I rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the vulcanite. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the Extra Fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection.

After finishing with the micromesh pads I rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the vulcanite. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the Extra Fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection.  The final steps in my process involve using the buffer. I buffed the stem with Blue Diamond to polish out the light scratches in the vulcanite. I don’t buff a sandblast bowl with Blue Diamond as it can easily clog the valley and crannies in the blast. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I follow up the wax buff with a buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It really is a nice pipe. The smooth finish around the bowl sides and shank looks great. The vulcanite saddle DC stem works well with the pipe. The sandblast Hilson S2 Stronghold Nosewarmer feels great in my hand. It is a well balanced pipe. Have a look at it with the photos below. The dimensions are Length: 4 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: ¾ inch. The weight of the pipe is 1.41 ounces/40 grams. It is a beautiful pipe that I will soon be adding to the rebornpipes store in the Pipes from Various Makers Section. If you would like to add it to your collection let me know. It should be a great smoking pipe.

The final steps in my process involve using the buffer. I buffed the stem with Blue Diamond to polish out the light scratches in the vulcanite. I don’t buff a sandblast bowl with Blue Diamond as it can easily clog the valley and crannies in the blast. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I follow up the wax buff with a buff with a clean buffing pad. It works to raise the shine and then I hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished stem. It really is a nice pipe. The smooth finish around the bowl sides and shank looks great. The vulcanite saddle DC stem works well with the pipe. The sandblast Hilson S2 Stronghold Nosewarmer feels great in my hand. It is a well balanced pipe. Have a look at it with the photos below. The dimensions are Length: 4 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: ¾ inch. The weight of the pipe is 1.41 ounces/40 grams. It is a beautiful pipe that I will soon be adding to the rebornpipes store in the Pipes from Various Makers Section. If you would like to add it to your collection let me know. It should be a great smoking pipe.

As always I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.