Blog by Steve Laug

The last of Steve’s pipes the remained for me to work on was a Hilson Fantasia. It is a Dublin shaped pipe made of resin with a meerschaum insert. It has a yellow coloured bowl and shank with swirls of green that are scattered throughout the pipe. When Steve sent me the box of pipes to work on I told him this one was not worth the effort to clean it up. It was in really rough shape on both the stem and the bowl insert. But in the end I decided to clean it and the Pipe just so he could see what these resin bowl pipes were like. I have cleaned a few of these up over the years that have almost psychedelic patterns in the resin. They are really a product of the 60s and 70s in my opinion. I took the following photos of the pipe before I started the clean up to show the general condition and give you some idea why I said the pipe was not worth cleaning up.  The pipe really was in rough condition. The meerschaum bowl was not readily identifiable and there was major damage to the rim top. There chunks of the inner bowl missing from the top at the back edge of the bowl. There was a seriously thick cake in the bowl that was fuzzy with dust and debris. The outer resin bowl was covered with a layer of lava. The stem would not fit in the shank the way it was supposed to which signaled that the shank was cake with about as much debris and the bowl. The stem was oxidized and there were tooth marks on both the top and the underside at the button. The button itself was worn away and no longer clearly defined. The outer resin bowl was in pretty good shape with no deep scratches or gouges.

The pipe really was in rough condition. The meerschaum bowl was not readily identifiable and there was major damage to the rim top. There chunks of the inner bowl missing from the top at the back edge of the bowl. There was a seriously thick cake in the bowl that was fuzzy with dust and debris. The outer resin bowl was covered with a layer of lava. The stem would not fit in the shank the way it was supposed to which signaled that the shank was cake with about as much debris and the bowl. The stem was oxidized and there were tooth marks on both the top and the underside at the button. The button itself was worn away and no longer clearly defined. The outer resin bowl was in pretty good shape with no deep scratches or gouges.  I was hoping that once I reamed the bowl it would be intact lower down. I was basing that hope on the fact that Hilson used block meerschaum and not pressed meerschaum for their bowls. That made the quality of the lining far better and I have rarely seen a Hilson meerschaum lining cracked or broken.

I was hoping that once I reamed the bowl it would be intact lower down. I was basing that hope on the fact that Hilson used block meerschaum and not pressed meerschaum for their bowls. That made the quality of the lining far better and I have rarely seen a Hilson meerschaum lining cracked or broken. The next two photos show the stamping on the pipe. On the underside of the shank it is stamped Belgium and on the right side it is stamped with the shape number 206. The normal stamping on the stem was long gone. So it no longer read Hilson Fantasia. For the identity I am going with the stamping that is visible, the shape and material of the pipe for calling it a Hilson Fantasia.

The next two photos show the stamping on the pipe. On the underside of the shank it is stamped Belgium and on the right side it is stamped with the shape number 206. The normal stamping on the stem was long gone. So it no longer read Hilson Fantasia. For the identity I am going with the stamping that is visible, the shape and material of the pipe for calling it a Hilson Fantasia. The photos of the stem show the condition of the oxidation and tooth marks on the surface as well as the worn condition of the button.

The photos of the stem show the condition of the oxidation and tooth marks on the surface as well as the worn condition of the button. I had previously researched the Hilson Fantasia for a blog I already did on a previous restoration. (https://rebornpipes.com/2016/07/05/is-it-really-a-plastic-smoking-pipe-what-is-a-hilson-fantasia/) On that blog I wrote of what I had found out about the brand. I had learned that the Hilson Fantasia was made in Belgium as this one was stamped. It originally came out as a meerschaum lined pipe with an outer bowl made of a new material that they called pipenite. From what I can find out about the material they call pipenite, it was a specially designed polyester resin. It was light weight and fairly indestructible. The block meerschaum insert was something that Hilson turned into a specialty. I had found a catalogue page on Chris’ Pipe pages, http://pipepages.com/hilson.htm that confirmed my guess regarding the 60s/70s look of the pipe. I have once again included a catalogue page from a 1962 Wally Frank Catalogue that was on the pipepages site. The write up on the Hilson Fantasia is entertaining to read in terms of the sales pitch that is delivered.

I had previously researched the Hilson Fantasia for a blog I already did on a previous restoration. (https://rebornpipes.com/2016/07/05/is-it-really-a-plastic-smoking-pipe-what-is-a-hilson-fantasia/) On that blog I wrote of what I had found out about the brand. I had learned that the Hilson Fantasia was made in Belgium as this one was stamped. It originally came out as a meerschaum lined pipe with an outer bowl made of a new material that they called pipenite. From what I can find out about the material they call pipenite, it was a specially designed polyester resin. It was light weight and fairly indestructible. The block meerschaum insert was something that Hilson turned into a specialty. I had found a catalogue page on Chris’ Pipe pages, http://pipepages.com/hilson.htm that confirmed my guess regarding the 60s/70s look of the pipe. I have once again included a catalogue page from a 1962 Wally Frank Catalogue that was on the pipepages site. The write up on the Hilson Fantasia is entertaining to read in terms of the sales pitch that is delivered. I have also written about some of the history of the brand on a previous blog on Hilson Double Ecume pipes. If you are interested in reading about the history of the brand click on the following link: https://wordpress.com/post/rebornpipes.com/40547. In addition the following link on the Estervals Pipe House website gives a good summary of the history of the brand for those of you who want to read more: http://www.tecon-gmbh.de/info_pages.php?pages_id=70.

I have also written about some of the history of the brand on a previous blog on Hilson Double Ecume pipes. If you are interested in reading about the history of the brand click on the following link: https://wordpress.com/post/rebornpipes.com/40547. In addition the following link on the Estervals Pipe House website gives a good summary of the history of the brand for those of you who want to read more: http://www.tecon-gmbh.de/info_pages.php?pages_id=70.

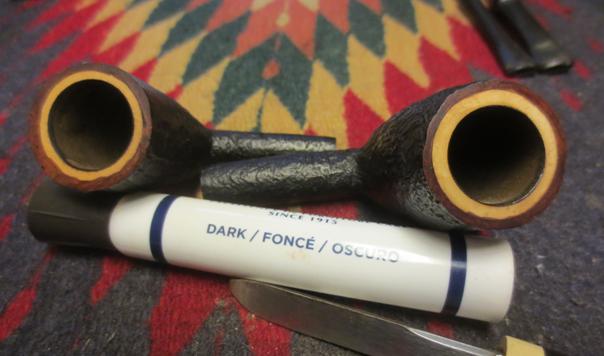

Now for the cleanup of the Fantasia! I carefully reamed the bowl with the smallest cutting head of the PipNet pipe reamer and cleaned up the inside of the bowl with a Savinelli Fitsall Pipe knife. I say carefully because I did not want to damage the meerschaum insert in the bowl but I wanted to remove the rock hard cake in the bowl. I topped the bowl carefully using a medium and a fine grit sanding pad. I wanted to smooth out the surface of the rim and remove the lava that was on top. I wanted to remove the lip of lava that had formed on the top of the bowl. The second photo below shows the cleaned rim top and also the damage that was very evident at the back edge of the bowl and around the sides.

I topped the bowl carefully using a medium and a fine grit sanding pad. I wanted to smooth out the surface of the rim and remove the lava that was on top. I wanted to remove the lip of lava that had formed on the top of the bowl. The second photo below shows the cleaned rim top and also the damage that was very evident at the back edge of the bowl and around the sides.  I cleaned out the shank of the pipe with a thin pen knife to scrape away the hardened tars that lined the inside walls. I followed that with a sanding stick and many pipe cleaners, cotton swabs and alcohol before the shank was clean.

I cleaned out the shank of the pipe with a thin pen knife to scrape away the hardened tars that lined the inside walls. I followed that with a sanding stick and many pipe cleaners, cotton swabs and alcohol before the shank was clean. The inner edge of the bowl was pitted and uneven so I sanded it with a piece of 220 grit sandpaper to smooth it out and to clean up the damaged area at the back of the bowl. It was not perfect but it looked better than when I started.

The inner edge of the bowl was pitted and uneven so I sanded it with a piece of 220 grit sandpaper to smooth it out and to clean up the damaged area at the back of the bowl. It was not perfect but it looked better than when I started. I took the stem out of the Before & After Pipe Stem Deoxidizer and wiped it down with a cotton pad. I cleaned out the inside of the stem with pipe cleaners and alcohol to remove the left over deoxidizer. The photos below show that it removed most of the oxidation but there were some stubborn spots left. The tooth dents are also very clear in the next photos of the stem. I wiped the stem down with alcohol and filled in the dents with a black super glue. I set the stem aside to let the repairs cure.

I took the stem out of the Before & After Pipe Stem Deoxidizer and wiped it down with a cotton pad. I cleaned out the inside of the stem with pipe cleaners and alcohol to remove the left over deoxidizer. The photos below show that it removed most of the oxidation but there were some stubborn spots left. The tooth dents are also very clear in the next photos of the stem. I wiped the stem down with alcohol and filled in the dents with a black super glue. I set the stem aside to let the repairs cure.

When the glue had cured I worked on the fit of the stem in the shank. The tenon was still too big for the stem to sit properly in the shank so I sanded it down with 220 grit sandpaper. There were some high spots on the tenon that needed to be rounded out and cleaned up. Once that was completed the stem fit perfectly.

When the glue had cured I worked on the fit of the stem in the shank. The tenon was still too big for the stem to sit properly in the shank so I sanded it down with 220 grit sandpaper. There were some high spots on the tenon that needed to be rounded out and cleaned up. Once that was completed the stem fit perfectly. Once the fit of the stem was correct, I turned to work on the stem itself. I wanted to blend the patched areas into the surface of the stem and also recut and redefine the button with needle files. I used a knife-edge needle file to redefine the sharp edge of the button and give it form. I also used it to flatten out the repaired areas on both sides of the stem.

Once the fit of the stem was correct, I turned to work on the stem itself. I wanted to blend the patched areas into the surface of the stem and also recut and redefine the button with needle files. I used a knife-edge needle file to redefine the sharp edge of the button and give it form. I also used it to flatten out the repaired areas on both sides of the stem. I smoothed out the repairs with 220 grit sandpaper and worked to blend them into the surface of the stem. I was a little concerned in that the repairs seemed to look almost red against the surface of the still oxidized vulcanite. I would have to work that to see if I could blend it in more. At worse the repairs will show but the pipe will be smokable.

I smoothed out the repairs with 220 grit sandpaper and worked to blend them into the surface of the stem. I was a little concerned in that the repairs seemed to look almost red against the surface of the still oxidized vulcanite. I would have to work that to see if I could blend it in more. At worse the repairs will show but the pipe will be smokable. Now the frustration heightened – I really should have listened to my initial thoughts on this pipe. It was not worth working on. But I did not listen and now one of the reasons became more apparent. I polished the stem with micromesh sanding pads. The more I polished them the more the two repaired spots on the top of the stem showed a red colour. I have never had that happen before. I cleaned the stems before patching them with alcohol and dried them off. I used black super glue for the repairs, like I have many times before. Yet this time the repairs show a red tint. I have no idea what is going on with this repair. Fortunately it is one that I am calling finished. It was just a quick clean up on a badly damaged pipe. The stem is functionally very good just those spots are irritating. I used micromesh sanding pads to polish the stem – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each pad and set it aside to dry after the 12000 grit pad.

Now the frustration heightened – I really should have listened to my initial thoughts on this pipe. It was not worth working on. But I did not listen and now one of the reasons became more apparent. I polished the stem with micromesh sanding pads. The more I polished them the more the two repaired spots on the top of the stem showed a red colour. I have never had that happen before. I cleaned the stems before patching them with alcohol and dried them off. I used black super glue for the repairs, like I have many times before. Yet this time the repairs show a red tint. I have no idea what is going on with this repair. Fortunately it is one that I am calling finished. It was just a quick clean up on a badly damaged pipe. The stem is functionally very good just those spots are irritating. I used micromesh sanding pads to polish the stem – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each pad and set it aside to dry after the 12000 grit pad.

I was irritated with the way the pipe looked – both bowl and stem. They were ragged looking still and even though they were better they were not what I like to see in a finished pipe. I was finished though as I decided that more work would not improve the damaged pipe. I buffed the bowl and stem with Blue Diamond on the buffing wheel. I hoped that the buffing might blend the repairs into the surface of the stem. While they certainly looked better they still showed. The overall look of the pipe was much better than when I started. The damage to the back side top edge of the meerschaum bowl liner was significant but the pipe was still able to be smoked. It was clean and would certainly make a workable yard pipe. I have boxed the pipe with the rest of Steve’s pipes and have them packed and ready to send to Dawson Creek. I am hoping he enjoys the lot and gives them a good workout in the days ahead. Thanks for looking.

I was irritated with the way the pipe looked – both bowl and stem. They were ragged looking still and even though they were better they were not what I like to see in a finished pipe. I was finished though as I decided that more work would not improve the damaged pipe. I buffed the bowl and stem with Blue Diamond on the buffing wheel. I hoped that the buffing might blend the repairs into the surface of the stem. While they certainly looked better they still showed. The overall look of the pipe was much better than when I started. The damage to the back side top edge of the meerschaum bowl liner was significant but the pipe was still able to be smoked. It was clean and would certainly make a workable yard pipe. I have boxed the pipe with the rest of Steve’s pipes and have them packed and ready to send to Dawson Creek. I am hoping he enjoys the lot and gives them a good workout in the days ahead. Thanks for looking.