by Steve Laug

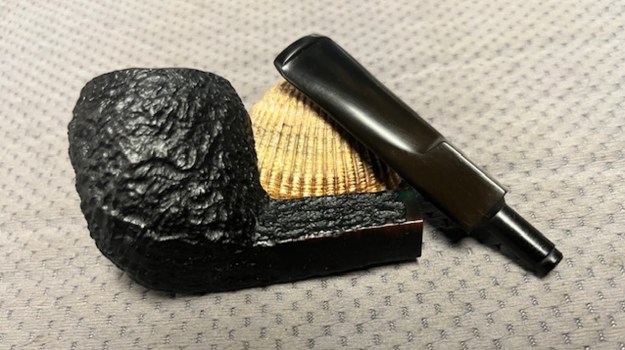

The next pipe on the table is a nice rusticated looking sandblast Bulldog shaped pipe. We purchased it from a seller in Downey, California, USA on 08/12/205. On the heel of the bowl it is stamped on a smooth panel on the left underside of the diamond shank. It reads Charatan’s Make [over]London. England. Underneath it is stamped with a cursive L near the bowl and the shape number 38 on the shank end. The pipe has a rugged, deep sandblast that I really like. The finish was very dirty with dust in all of the rustication, making it hard to see beyond that to the finish underneath that. There was a thick cake in the bowl and a heavy overflow of lava filling in the sandblast on the rim top. It was hard to know at this point the condition of the rim edges. The stem was oxidized, calcified and there were light tooth marks and chatter on both sides just ahead of the button. The stem has the Charatan’s CP logo on the top left side of the diamond saddle stem and it is faint but readable. I am not sure if it is deep enough to survive the clean up. Jeff took photos of the pipe before he started working on it. I include those below.

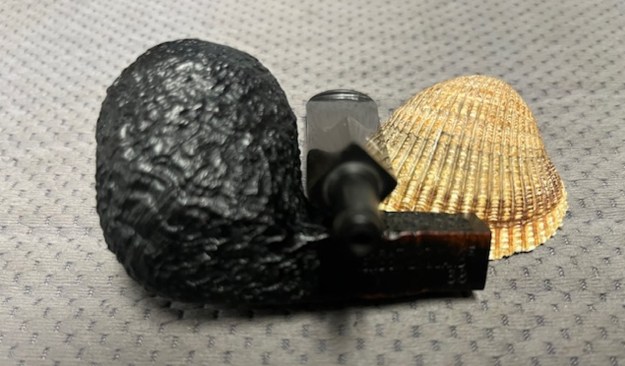

Jeff took photos of the bowl and rim top to show the cake in the bowl and the lava build up on the rim top and dust and grime in the sandblast. It was thick and hard but hopefully it had protected the rim and edges from damage. The lava is deep in the blast and there is a buildup on the inner edge of the bowl. The stem shows oxidation, calcification and marks as noted above.

Jeff took photos of the bowl and rim top to show the cake in the bowl and the lava build up on the rim top and dust and grime in the sandblast. It was thick and hard but hopefully it had protected the rim and edges from damage. The lava is deep in the blast and there is a buildup on the inner edge of the bowl. The stem shows oxidation, calcification and marks as noted above.

Jeff took a photo of the sides and heel of the bowl to show the condition of the finish – the grime and grit all over the sides and bottom of the bowl. The blast is deep and dirty but it is interesting. This is a very tactile finish and one that I enjoy.

Jeff took a photo of the sides and heel of the bowl to show the condition of the finish – the grime and grit all over the sides and bottom of the bowl. The blast is deep and dirty but it is interesting. This is a very tactile finish and one that I enjoy.

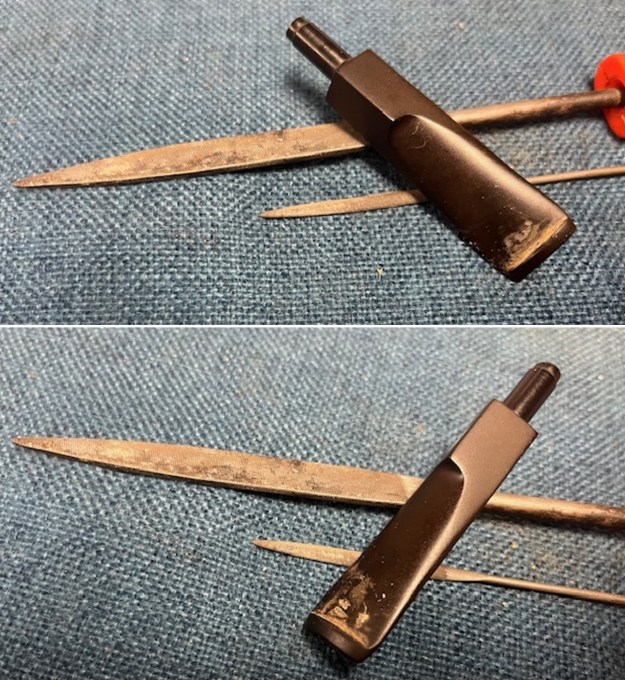

Jeff took a photo of the stamping on the left underside of the shank and the CP stamp on the diamond saddle of the stem. It is very clear and readable as noted above.

Jeff took a photo of the stamping on the left underside of the shank and the CP stamp on the diamond saddle of the stem. It is very clear and readable as noted above. This pipe was a real mess like many of the pipes we work on. I was curious to see what it would look like when I unpacked it. I was surprised at how good it looked. Jeff reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish on the bowl looked really good when I got it. The rim top looked much better and the inner and outer edges were looking good. There was some debris in the grooves of the rim top that still needed to be picked out. He had cleaned the internals and scrubbed the exterior of the stem and soaked them in Briarville’s Pipe Stem Deoxidizer bath to remove the oxidation. The stem looked very good other than the very light tooth marks and chatter in the surface. I took photos of the pipe before I started my work on it.

This pipe was a real mess like many of the pipes we work on. I was curious to see what it would look like when I unpacked it. I was surprised at how good it looked. Jeff reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish on the bowl looked really good when I got it. The rim top looked much better and the inner and outer edges were looking good. There was some debris in the grooves of the rim top that still needed to be picked out. He had cleaned the internals and scrubbed the exterior of the stem and soaked them in Briarville’s Pipe Stem Deoxidizer bath to remove the oxidation. The stem looked very good other than the very light tooth marks and chatter in the surface. I took photos of the pipe before I started my work on it.

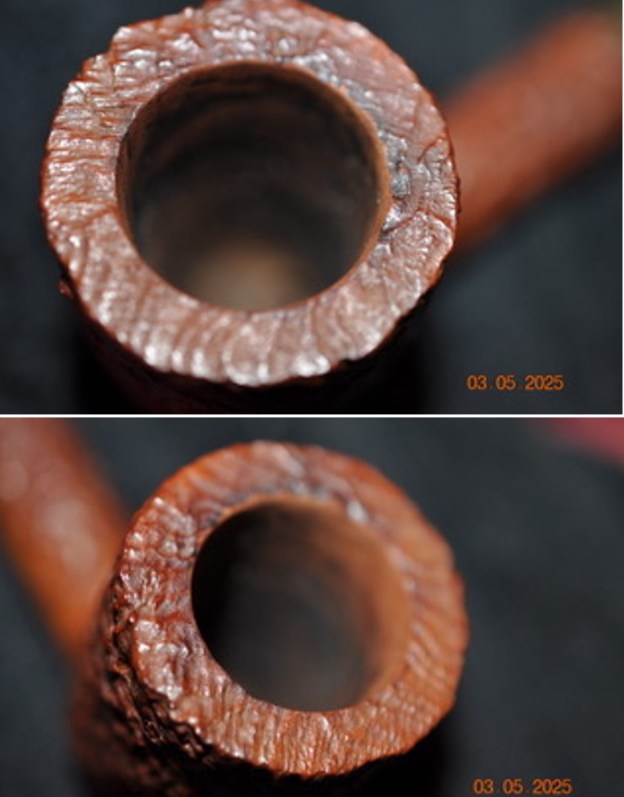

I took photos of the condition of the rim top and stem before I started working. The rim top looks very good. The crevices and valleys of the rustication are clean and look great. The bowl is spotless. The stem is lightly oxidized and has some tooth marks and tooth chatter. The Savinelli S shield on the top of the stem is worn and very shallow. It will be hard to save in the clean up work.

I took photos of the condition of the rim top and stem before I started working. The rim top looks very good. The crevices and valleys of the rustication are clean and look great. The bowl is spotless. The stem is lightly oxidized and has some tooth marks and tooth chatter. The Savinelli S shield on the top of the stem is worn and very shallow. It will be hard to save in the clean up work.  I took a photo of the stamping on the underside of the heel and the shank. It is clear and readable as noted above. I took the bowl and stem apart and took a photo of the pipe to show the look of the pipe.

I took a photo of the stamping on the underside of the heel and the shank. It is clear and readable as noted above. I took the bowl and stem apart and took a photo of the pipe to show the look of the pipe. I started my work on the pipe by working over the rim top with a brass bristle wire brush to remove the debris deep in the grooves of the rim top. It was looking much better.

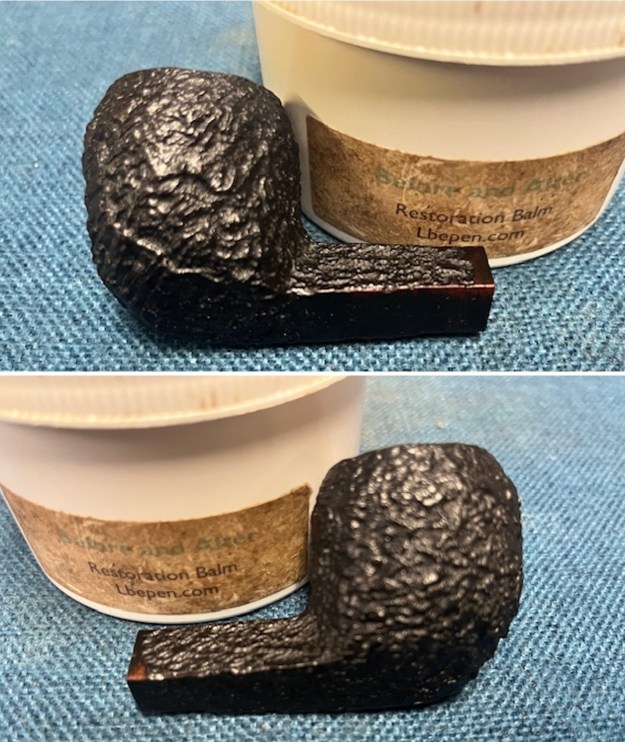

I started my work on the pipe by working over the rim top with a brass bristle wire brush to remove the debris deep in the grooves of the rim top. It was looking much better.  It was ready for the next step. I worked some Before & After Restoration Balm into the finish of the bowl and the rim top and shank with my fingertips and a horsehair shoe brush to clean, enliven and protect it. I find that the balm really makes the briar come alive again. The contrasts in the layers of stain and the separate finishes really made the grain stand out. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The bowl really looks good at this point.

It was ready for the next step. I worked some Before & After Restoration Balm into the finish of the bowl and the rim top and shank with my fingertips and a horsehair shoe brush to clean, enliven and protect it. I find that the balm really makes the briar come alive again. The contrasts in the layers of stain and the separate finishes really made the grain stand out. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The bowl really looks good at this point.

I filled in the tooth marks on the top and underside with clear CA glue and set it aside to cure. Once cured I used a small file to flatten the repair and then sanded it with 220 grit sandpaper to blend it into the surface of the vulcanite.

I filled in the tooth marks on the top and underside with clear CA glue and set it aside to cure. Once cured I used a small file to flatten the repair and then sanded it with 220 grit sandpaper to blend it into the surface of the vulcanite.

I touched up the CP stamp with white acrylic nail polish. I scraped off the excess and smoothed it out with a worn 1500 grit sanding pad.

I touched up the CP stamp with white acrylic nail polish. I scraped off the excess and smoothed it out with a worn 1500 grit sanding pad. I sanded the stem to further blend in the repairs with 320-3500 grit 2 inch square sanding pads. I wiped down the stem with an Obsidian Oil Cloth after each sanding pad. At this point the stem is looking better and the repairs blended in well. The CP stamp also looked very good.

I sanded the stem to further blend in the repairs with 320-3500 grit 2 inch square sanding pads. I wiped down the stem with an Obsidian Oil Cloth after each sanding pad. At this point the stem is looking better and the repairs blended in well. The CP stamp also looked very good.  I polished the stem with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped it down with an Obsidian Oil cloth after each pad. I polished it further with Before & After Pipe Stem Polish – both fine and extra fine. I gave it another wipe down with the Obsidian Oil cloth and buffed it to a shine.

I polished the stem with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I wiped it down with an Obsidian Oil cloth after each pad. I polished it further with Before & After Pipe Stem Polish – both fine and extra fine. I gave it another wipe down with the Obsidian Oil cloth and buffed it to a shine.

Once again, I am at the part of the restoration that I always look forward to – the moment when all the pieces are back together. I put the Lane Era Charatan’s Make London England 38 Bulldog back together and lightly buffed the bowl with Blue Diamond. I buffed the stem with a heavier touch with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like in contrast with the black vulcanite stem. This dark stained Charatan’s Make 38 Straight Bulldog must have been a fine smoking pipe judging from the condition it was in when I started. Have a look at it in the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.23 ounces/35 grams. This is one that will go on the British Pipemakers Section of the rebornpipes online store shortly. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.

Once again, I am at the part of the restoration that I always look forward to – the moment when all the pieces are back together. I put the Lane Era Charatan’s Make London England 38 Bulldog back together and lightly buffed the bowl with Blue Diamond. I buffed the stem with a heavier touch with Blue Diamond on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like in contrast with the black vulcanite stem. This dark stained Charatan’s Make 38 Straight Bulldog must have been a fine smoking pipe judging from the condition it was in when I started. Have a look at it in the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.23 ounces/35 grams. This is one that will go on the British Pipemakers Section of the rebornpipes online store shortly. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.