Blog by Steve Laug

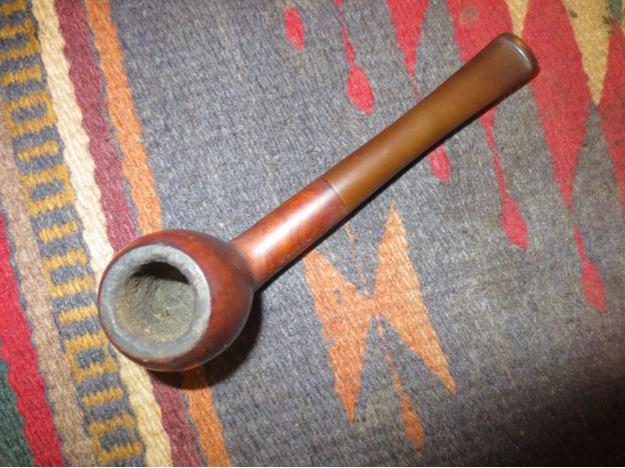

The next pipe on the work table came to me from the estate of a Vancouver pipe smoker whose widow left them with a local Pipe Shop after he died. I was asked to clean them up and sell them for the shop as it has since closed. This American Made Benson & Hedges Peewit is an interesting looking piece – great grain showing through underneath the grime. There is cross grain and birdseye grain around the bowl. The pipe is stamped on the left side and reads Benson & Hedges and on the right side it is stamped Made in U.S.A. The finish was dull and lifeless with a lot of grime ground into the briar. The bowl was heavily caked with a lava coat on the top of the rim. It was hard to tell how the inner and outer edge of the rim actually looked until the bowl was reamed. The stem was oxidized, calcified and had tooth chatter and marks on the top and underside near the button. It had promise but it was very dirty. I took some photos of the pipe when I received it.

I was curious about the maker of the pipe so I did some searching. In Who Made that Pipe it says that the pipe is English Made even though this one says Made in USA. In Pipedia says that it was likely made by Comoy for the London Tobacco Company. Then it lists the following stamping “London Made”. http://pipedia.org/wiki/British_Pipe_Brands_%26_Makers_A_-_D There was one other note that Orlik made pipes that were stamped with the Benson and Hedges label. Nowhere in the listings that I could find did anyone mention the stamping on this one: MADE IN U.S.A. Even though many B&H pipes were made in England by noted English Pipe Makers this one is obviously not one of those. I can find no mention of an American Maker for the brand so I guess this is one mystery that I can go no further in unraveling. Now it was time to work on the pipe.

I was curious about the maker of the pipe so I did some searching. In Who Made that Pipe it says that the pipe is English Made even though this one says Made in USA. In Pipedia says that it was likely made by Comoy for the London Tobacco Company. Then it lists the following stamping “London Made”. http://pipedia.org/wiki/British_Pipe_Brands_%26_Makers_A_-_D There was one other note that Orlik made pipes that were stamped with the Benson and Hedges label. Nowhere in the listings that I could find did anyone mention the stamping on this one: MADE IN U.S.A. Even though many B&H pipes were made in England by noted English Pipe Makers this one is obviously not one of those. I can find no mention of an American Maker for the brand so I guess this is one mystery that I can go no further in unraveling. Now it was time to work on the pipe.

I had sent the batch of pipes from the shop to my brother Jeff in Idaho and he had cleaned them up for me. It was several years ago now that he sent them back to me and I am just now getting to finish them. He reamed them with a Pipnet Reamer and cleaned up the reaming with a Savinelli Fitsall pipe knife. He had scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush and rinsed it off with warm water to remove the grime in the rustication. He cleaned the internals of the shank and stem with alcohol, cotton swabs and pipe cleaners to remove the tarry residue and oils in the shank and airway. He soaked the stem in Before & After Deoxidizer to remove the oxidation on the stem surface. When it arrived here on my work table I took photos of the pipe before I started my part of the restoration. The bowl was a definite improvement but the stem still showed a lot of oxidation.

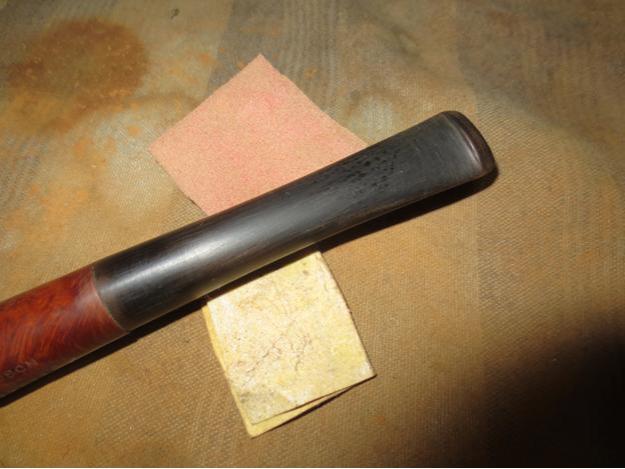

The rim top looked really good. The inner and outer edges were in excellent condition. There was no charring or damage to the top or edges. I was pleased. The stem look good but there was still some heavy oxidation and there were tooth marks and chatter on both sides near the button. The underside was worse than the topside.

The rim top looked really good. The inner and outer edges were in excellent condition. There was no charring or damage to the top or edges. I was pleased. The stem look good but there was still some heavy oxidation and there were tooth marks and chatter on both sides near the button. The underside was worse than the topside.  I took a photo of the stamping on the sides of the shank. The stamping is clear and readable and reads as noted above.

I took a photo of the stamping on the sides of the shank. The stamping is clear and readable and reads as noted above.  I took the stem off the pipe and took a photo of the parts to show the look of the pipe as a whole.

I took the stem off the pipe and took a photo of the parts to show the look of the pipe as a whole. The pipe was in great condition so I moved to polishing the bowl with micromesh sanding pads. I sanded it with 1500-12000 grit pads and wiped it down between each pad with a damp cloth. By the end you can see the shine on the briar.

The pipe was in great condition so I moved to polishing the bowl with micromesh sanding pads. I sanded it with 1500-12000 grit pads and wiped it down between each pad with a damp cloth. By the end you can see the shine on the briar.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. You can see the grain showing through the deep glow.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. You can see the grain showing through the deep glow.

I “painted” the stem surface with the flame of a Bic lighter. I filled in the remaining tooth marks with black super glue. Once it cured I smoothed out the surface of the repair with a needle file.

I “painted” the stem surface with the flame of a Bic lighter. I filled in the remaining tooth marks with black super glue. Once it cured I smoothed out the surface of the repair with a needle file.

I sanded out the repair with 220 grit sandpaper to blend it into the surface of the surrounding vulcanite. I started polishing the stem with 400 grit wet dry sandpaper.

I sanded out the repair with 220 grit sandpaper to blend it into the surface of the surrounding vulcanite. I started polishing the stem with 400 grit wet dry sandpaper.  I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Benson & Hedges Peewit made in USA is nice Danish looking pipe that came to me from the local pipe shop estate that I am restoring and selling for them. It has turned out to be a great looking pipe. The medium brown finish highlights the grain and works well with the polished vulcanite saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peewit fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. If you are interested in adding this pipe to your collection send me a message or an email. I have a variety of brands to work on from the shop. Perhaps one of those will catch your attention. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.

This Benson & Hedges Peewit made in USA is nice Danish looking pipe that came to me from the local pipe shop estate that I am restoring and selling for them. It has turned out to be a great looking pipe. The medium brown finish highlights the grain and works well with the polished vulcanite saddle stem. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peewit fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. If you are interested in adding this pipe to your collection send me a message or an email. I have a variety of brands to work on from the shop. Perhaps one of those will catch your attention. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.