Blog by Steve Laug

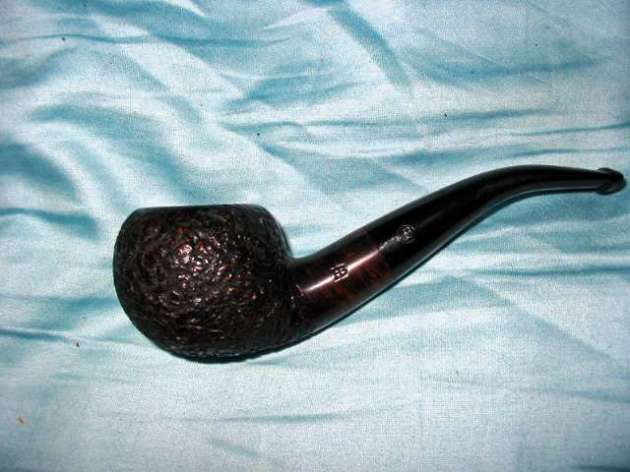

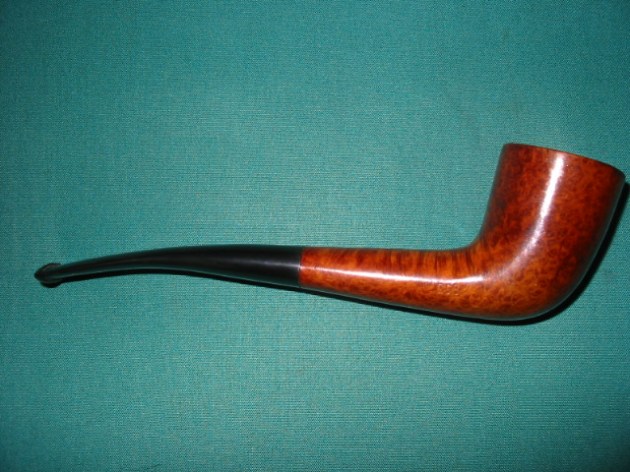

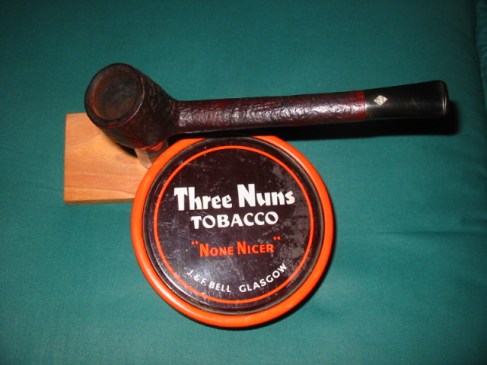

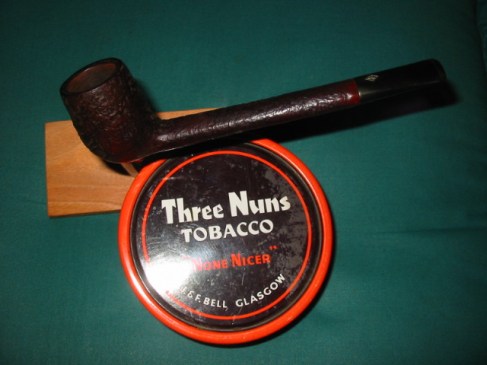

I have had this old Sasieni Mayfair on my desk for a long time. It had come to me in a box of stummels/bowls that I received from a friend over a year ago. It sat for several months in that box before I took it and cleaned it up. I reamed and cleaned the bowl and had even restained it after it had an alcohol bath. I had restemmed it after that with a Lucite tapered butterscotch coloured stem. It looked nice and fit well but something did not quite work with the combination in my opinion. I had it sitting on the table for several months with that stem. I smoked it occasionally and looked it over but never really like the way the stem looked with the old pipe. It seemed like two different eras were colliding in the combination of the old bowl and the new stem so it just sat on the table.

One day after I had finished the pipes that I was working on and was not quite ready to close up shop for the night I picked up the Sasieni. I turned it over in my hands debating with myself what to do with it. It did not take long before I decided to restem it with a vulcanite stem. So I found a stem in my can of stems that was the right shape and angles on the slope of the stem and turned the tenon and fit it to the pipe. Even with just that much work the stem looked like it was a better choice for the pipe. I then used my Dremel with the sanding drum to take down the rest of the stem to fit the shank and band. Once I had a good fit I used emery cloth, 240 grit sandpaper and 400 and 600 wet dry sandpaper and water to smooth out the sanding scratches and marks from the drum and to fine tune the fit. I opened up the button with needle files and also funneled the end of the tenon for a smooth airflow. Once it was finished I took it to the buffer and buffed the pipe with White Diamond and several coats of carnauba wax.

I liked the look of the pipe immediately and knew that the new stem was the ticket to returning this old pipe to its former glory. Now with the new stem I find myself reaching for it regularly.