By Al Jones

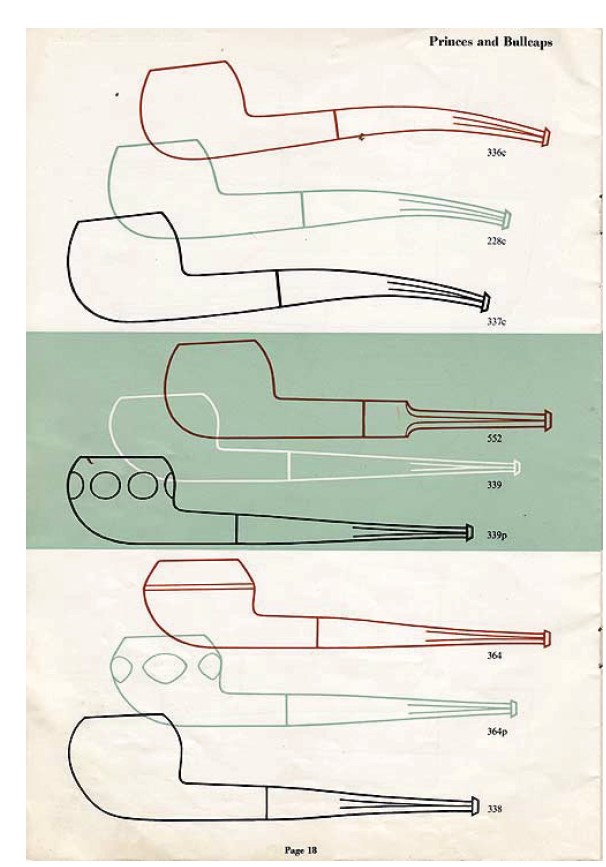

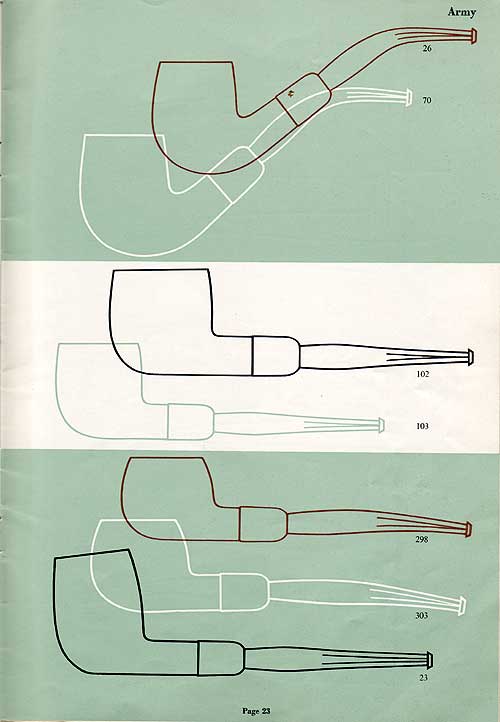

The Sasieni Ashford Author is a classic shape for that brand, with the shape chart number 88. The shape was used by first line Four Dot pipes as well as a myriad of second-line brands. This second line pipe is stamped a “Royal Stuart”.

I found this one on Ebay and I had been following this seller, since she had a number of shape 88 pipes listed. The listing said that the pipes were from her fathers collection. I missed on several similar shapes and was pleased to win the auction for this one. I messaged the seller and asked if she could tell me more about the pipes or her father. We exchanged a number of messages and the seller agreed that I could share her personal recollections. The pipes sold belonged to her father and perhaps her grandfather and she describes them below. They lived in Dayton, Ohio.

My father was Victor Waltz and he and his father smoked pipes. My father died about 23 years ago and in my house I found a box of pipes labeled pipes box #2. I have no idea what happened to box #1? It is possible that the 32 pipes in the box about the size of a shoebox may have included some that were my grandfather’s, also Victor Waltz. I just remember the pipe tobacco as smelling sweet and mellow and being kept either in a round green humidor of a leather zipper pouch. The smoke shop in Dayton may be been Bob White’s. In the box there were three pipes with this name on them and a cranky old man told me that was the name of a smoke shop in Dayton at one time.

Question is why would one or two men even three need so many pipes- lol. Guess if you forgot your pipe may be easier to walk to the shop than drive home?

She also included a picture of her father below. You can see a Dutch Masters cigar box on the table! She does have his silver-hallmarked smoking stand to remember him.

This question made me chuckle a bit and I explained to her that collecting was the nature of pipe smokers – but her father/grandfather certainly had a passion for Sasieni second lines and more specifically the Shape 88/Ashford. In her auctions, I counted 19 Shape 88 or similar shape pipes! As a collector who definitely has a shape focus, I understand the focus on this group. I wish that it was possible to speak to her father about his fondness for this shape and the Sasieni brand.

I reached out to pipe historian, Jon Guss, to see if he had any information about Bob White’s shop in Dayton. Sure enough, Jon delivered quite a bit about Bob Whites. From the details below, and what Victors daughter shared, I believe the pipes were acquired during the Carlson era of the shop, which ended in 1991.

Robert D. White (1911-1966) established Bob White’s Cigar Stand in the lobby of the Winters Bank building, located at 42 Main in downtown Dayton Ohio, about 1937. He continued to operate it until his death almost thirty years later. The business was taken over by Carl M. Carlson (1926-2005) and operated with the help of his wife, Helen. Within a couple of years it had been renamed the Bob White Cigar and Pipe shop. The original location in downtown Dayton was closed by the Carlsons in early 1971, and moved to 2415 Far Hills Avenue in nearby Oakwood where it remained until the business was closed for good in early 1991.

Since its earliest days Bob White had been advertising the availability of Sasieni and Peterson pipes.

Thanks to Rob Schlef, on the Pipes & Tobacco Facebook page who read the blog entry and was familiar with the Bob White shop. He posted this business card for the shop, which mentions Sasieni and Peterson pipes.

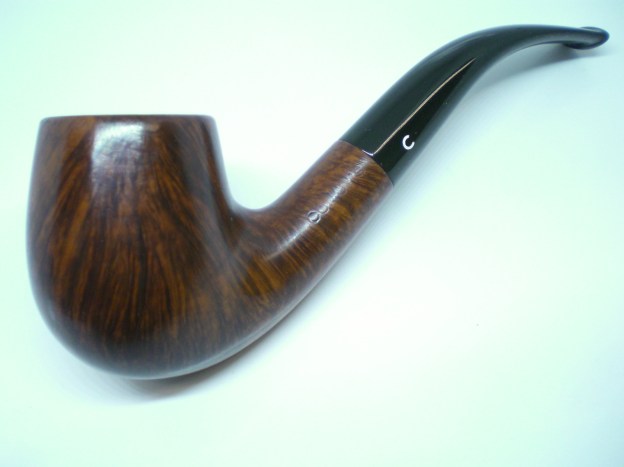

The pipes were all well-loved by Victor with all typical bumps and bruises found on a 50 to 60 year old pipe, that had been stored in a shoe box. The bowl top was a little rough, and there were some blemishes and one fill. The stem was tight fitting with a few shallow teeth indentions. Below is the pipe as it was received.

The first order of business was to clean up the bowl top. Once the build-up on the top was removed, it showed a number of very shallow chips and marks. I decided that a slight topping was in order and I thought that I could match the finish. I used 400 paper wet, flat on my work bench to get the bowl top back to an original condition.

I applied a coat of Fieblings Dark Brown stain, then sanded it smooth with 800, 1,000 an 1,500 wet paper, than another coating of stain, set with a flame The Dark Brown matched very nicely. I used an electric iron on High and a wet cloth to steam out several dings. A few remain, but the patina seems to fit and a part its past and use by Victor. I reamed the cake and found the bowl in very good condition. I then did the alcohol and sea salt soak. The shank was cleaned thoroughly and the briar was buffed with White Diamond and several coats of Carnuba wax. I was careful around the shallow nomenclature stamping.

Following the soak, I turned my attention to the stem. Mounted back on the pipe, I used a flame to lift the shallow teeth indentions. The mild oxidation was removed with 800, 1,500 and 2,000 grade wet paper. I used a Magic Eraser pad around the shallow RS stem stamp. This was followed by 8,000 and 12,000 micromesh sheets. The stem was then buffed with White Diamond and Meguiars Plastic Polish. I find Sasieni seconds line stems to be first rate and this one is a great example

The bowl was buffed lightly with White Diamond and several coats of Carnuba Wax. Below is the finished pipe. A raised pipe to Victor Waltz for such great taste in pipes!