by Steve Laug

I have been working lately replacing tenons on bowls in my own work box. After 6 of them I am ready for something different. While I was in Florence, Italy I had received and email from Jack regarding some pipes that he had that needed some work. Here is his email.

I have a Dunhill from unknown era, a Hardcastle, and possibly a third pipe that could use your workmanship. If you’d like, I can send you pictures of the pipes so you know what condition they’re in. Please let me know the necessary details! — Jack

We chatted about that and I suggested he email me when I returned to Canada. He wrote back and asked me to work on not three but four pipes. He listed what he had and I thought these would be an interesting diversion from tenon replacement work.

Are you still willing to entertain restoring/refurbishing a few pipes? I have four in various stages of need, and I’ve attached pictures of each for your evaluation. I would be very grateful for anything that you could and would be willing to do.

- 1992 (?) Dunhill

- Bertram 80

- Hardcastle – This pipe looks very clean except for some pitting? fissures? in the chamber.

- Dr. Grabow Supreme – This poor pipe… well, it’s a doozy.

Thank you very much! – Jack

I agreed and asked that he send them to me. Interestingly they arrived the day I finished the last of the tenon replacements. I unpacked them and they were indeed as interesting as his email had led me to believe. I decided to work on the second pipe listed in the foursome next – the Bertram 80. Here are the photos he sent to me of that pipe. I will give my evaluation of the work that will need to be done on the pipe as I walk through the photos with you.

The first two photos that Jack sent show the overall condition of the pipe. You can see from these photos that the rim top had a thick coat of lava on the rim and inner edge of the bowl. There is a thick cake that is rock hard and fills the bowl. The finish is very dirty but does not look to damaged with scratches or nicks in the photos. It is thoroughly dull under the grime.The stem is oxidized, calcified and had tooth marks on the top and the underside. The stamping on the left side of the shank is clear and readable. It reads Bertram over Washington, D.C. in a banner. Next to the bowl/shank junction is the grade number 80 stamp. The next two photos affirm my evaluation of the thick cake in the bowl and overflow of lava on the rim top. Fortunately there do not appear to be any cracks on the rim top or sides of the bowl.

The next two photos affirm my evaluation of the thick cake in the bowl and overflow of lava on the rim top. Fortunately there do not appear to be any cracks on the rim top or sides of the bowl.  I unpacked the pipes when they arrived on Thursday and went over each one. As I examined this one my observations based on the photos were confirmed. The one thing that was better was that the finish actually looked better in person than in the photos. There was some nice grain around the bowl that was a bit obscured by the oils and grime. The cake and the lava were as expected. They were both thick and hard as I had guessed from the photos. The stamping on the shank was clear and readable. The stamp read Bertram [over] Washington, D.C. in an unfurled banner. To the left of the stamping next to the bowl was the number 80 which was the grade stamp of the pipe. Just a note, I have yet to quite understand the grade stamps as I have worked on grade 20 pipes with absolutely stunning grain and higher grades with fills. It really is inexplicable. The stem looked as noted above. It was oxidized, calcified and had tooth chatter and marks on both sides ahead of the button. There was no stamp or logo on the stem as is normal for Bertram pipes. Have a look at the photos below.

I unpacked the pipes when they arrived on Thursday and went over each one. As I examined this one my observations based on the photos were confirmed. The one thing that was better was that the finish actually looked better in person than in the photos. There was some nice grain around the bowl that was a bit obscured by the oils and grime. The cake and the lava were as expected. They were both thick and hard as I had guessed from the photos. The stamping on the shank was clear and readable. The stamp read Bertram [over] Washington, D.C. in an unfurled banner. To the left of the stamping next to the bowl was the number 80 which was the grade stamp of the pipe. Just a note, I have yet to quite understand the grade stamps as I have worked on grade 20 pipes with absolutely stunning grain and higher grades with fills. It really is inexplicable. The stem looked as noted above. It was oxidized, calcified and had tooth chatter and marks on both sides ahead of the button. There was no stamp or logo on the stem as is normal for Bertram pipes. Have a look at the photos below.

I took close up photos of the bowl and rim top to show the condition of both the bowl and the rim top. The bowl has a thick cake that lining the walls and overflowing into lava. You can see the lava and build up on the rim top and the lava flowing over the inner edge of the bowl. It is hard to know if there is damage or if the lava protected it. The stem is oxidized, calcified and has tooth marks and chatter on both sides ahead of the button.

I took close up photos of the bowl and rim top to show the condition of both the bowl and the rim top. The bowl has a thick cake that lining the walls and overflowing into lava. You can see the lava and build up on the rim top and the lava flowing over the inner edge of the bowl. It is hard to know if there is damage or if the lava protected it. The stem is oxidized, calcified and has tooth marks and chatter on both sides ahead of the button. I tried to capture the stamping on the shank to show their condition before my work. They are clear and readable as noted above. I removed the stem from the bowl and took a photo of the parts to give a sense of the symmetry of the pipe. It is a beauty beneath all grime.

I tried to capture the stamping on the shank to show their condition before my work. They are clear and readable as noted above. I removed the stem from the bowl and took a photo of the parts to give a sense of the symmetry of the pipe. It is a beauty beneath all grime. As always, I like to go back and read about the brand. In this case the Bertram name is one that I am very familiar with. Instead of going to Pipephil or to Pipedia I went to my own blog. I am including the information that I read below along with the links to further blog articles for you to have a look at.

As always, I like to go back and read about the brand. In this case the Bertram name is one that I am very familiar with. Instead of going to Pipephil or to Pipedia I went to my own blog. I am including the information that I read below along with the links to further blog articles for you to have a look at.

As I have worked on Bertrams I have written on the brand and have included the following information. If you have read it in past blogs, you can skip over it. If you have not, I have included the link to Bertram history and information. I would recommend that if you don’t know much about them take some time to read the background. I include a link to the write up on Pipedia (http://pipedia.org/wiki/Bertram). Bertram pipes were based out of Washington DC. They were popular among famous politicians and celebrities of the time. They made many products for them from FDR’s cigarette holders to Joseph Stalin’s favorite pipe. They were considered some of the best America had to offer till they finally closed their doors in the 70s. Bertram graded their pipes by 10s and sometimes with a 5 added (15, 25, 55 etc.), the higher the grade the better. Above 60s are uncommon and 80-90s are quite rare. I have worked on one 120 Grade billiard. I have several blogs that I have written on rebornpipes that give some history and background to Bertram pipes. (https://rebornpipes.com/2015/06/16/an-easy-restoration-of-a-bertram-grade-60-217-poker/).

As I have worked on Bertrams I have written on the brand and have included the following information. If you have read it in past blogs, you can skip over it. If you have not, I have included the link to Bertram history and information. I would recommend that if you don’t know much about them take some time to read the background. I include a link to the write up on Pipedia (http://pipedia.org/wiki/Bertram). Bertram pipes were based out of Washington DC. They were popular among famous politicians and celebrities of the time. They made many products for them from FDR’s cigarette holders to Joseph Stalin’s favorite pipe. They were considered some of the best America had to offer till they finally closed their doors in the 70s. Bertram graded their pipes by 10s and sometimes with a 5 added (15, 25, 55 etc.), the higher the grade the better. Above 60s are uncommon and 80-90s are quite rare. I have worked on one 120 Grade billiard. I have several blogs that I have written on rebornpipes that give some history and background to Bertram pipes. (https://rebornpipes.com/2015/06/16/an-easy-restoration-of-a-bertram-grade-60-217-poker/).

I have included the following link to give a bit of historical information on the pipe company. It is a well written article that gives a glimpse of the heart of the company. http://www.streetsofwashington.com/2012/01/bertrams-pipe-shop-on-14th-street.html#

From this information I learned that all of these Bertrams were made before the closure of the shop in the 1970s. This Bertram Straight Apple with stunning grain has one fill on the shank. This pipe has a 80 Grade stamp on it which I am sure explains the quality of the briar.

I decided to ream the bowl and do some internal clean up work before further polishing the briar. The cake was very hard so I proceeded with care so as not to either break my reamer or damage the rim edges. I reamed the bowl with a PipNet pipe reamer using the 1st and 2nd cutting heads to remove the cake in the bowl. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife and finally sanded the bowl with 220 grit sandpaper wrapped around a piece of dowel to clean up the walls of the bowl. The walls appeared to be in good condition.

I scraped the lava on the rim top with the Savinelli Fitsall knife and a folded piece of 220 grit sandpaper. I was able to remove the majority of it. There was some light damage to the inner edge that would need to be addressed.

I scraped the lava on the rim top with the Savinelli Fitsall knife and a folded piece of 220 grit sandpaper. I was able to remove the majority of it. There was some light damage to the inner edge that would need to be addressed. I scrubbed out the internals with pipe cleaners (normal & bristle), cotton swabs and alcohol to remove the tars and oils in the shank between the mortise and the entrance of the airway into the bowl. It was quite dirty.

I scrubbed out the internals with pipe cleaners (normal & bristle), cotton swabs and alcohol to remove the tars and oils in the shank between the mortise and the entrance of the airway into the bowl. It was quite dirty. I scrubbed the bowl and rim top with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime. I rinsed it with warm water and dried it off with a cotton towel. The grain really began to stand out. Polishing would only make it more prominent.

I scrubbed the bowl and rim top with undiluted Murphy’s Oil Soap and a tooth brush to remove the grime. I rinsed it with warm water and dried it off with a cotton towel. The grain really began to stand out. Polishing would only make it more prominent.

I worked over the damaged inner edge of the bowl with a folded piece of 220 grit sandpaper and smoothed out the nicks in the briar. I gently topped the bowl on a topping board with 220 grit sandpaper. While it was better, there was still some darkening and light damage to the back left side of the inner edge. I used a wooden sphere and a piece of 220 grit sandpaper to work in the top and the inner edge of the rim to minimize the damage on the edge. It looked very good once it was finished.

I worked over the damaged inner edge of the bowl with a folded piece of 220 grit sandpaper and smoothed out the nicks in the briar. I gently topped the bowl on a topping board with 220 grit sandpaper. While it was better, there was still some darkening and light damage to the back left side of the inner edge. I used a wooden sphere and a piece of 220 grit sandpaper to work in the top and the inner edge of the rim to minimize the damage on the edge. It looked very good once it was finished.

I sanded the bowl, rim top and shank with sanding pads – 320-3500 grit pads. I wiped the bowl down after each sanding pad to remove grime and check the progress. It was looking very good by the time I finished with the final pad.

I sanded the bowl, rim top and shank with sanding pads – 320-3500 grit pads. I wiped the bowl down after each sanding pad to remove grime and check the progress. It was looking very good by the time I finished with the final pad.

I polished the rim top and bowl with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad to remove the dust and debris. The grain stood out more with each set of pads.

I polished the rim top and bowl with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down with a damp cloth after each sanding pad to remove the dust and debris. The grain stood out more with each set of pads.

I worked some Before & After Restoration Balm into the finish of the bowl, rim top and shank with my fingertips to clean, enliven and protect it. I find that the balm really makes the briar come alive again. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The bowl really looks good at this point.

I worked some Before & After Restoration Balm into the finish of the bowl, rim top and shank with my fingertips to clean, enliven and protect it. I find that the balm really makes the briar come alive again. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The bowl really looks good at this point.

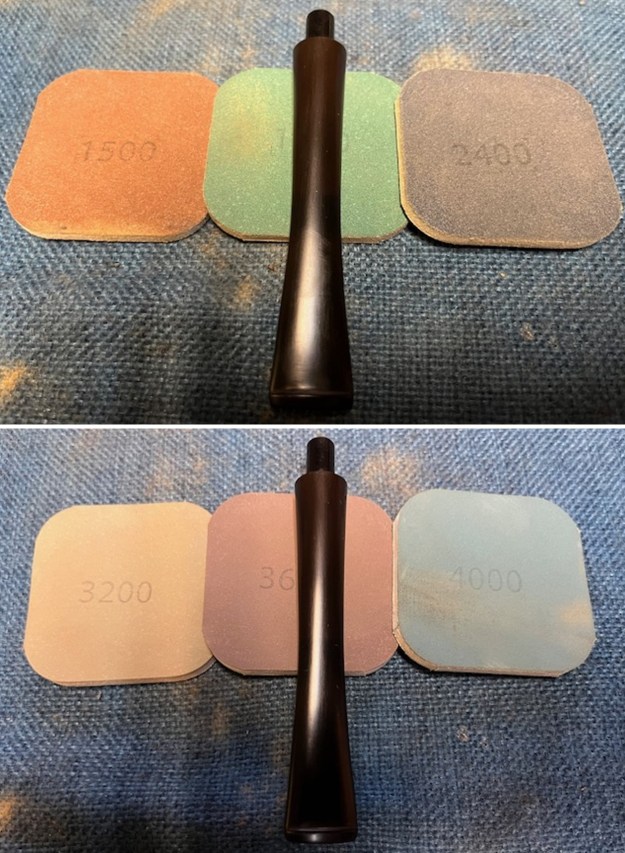

I set the bowl aside and turned my attention to the stem. I sanded the stem with 320-3500 grit sanding pads and wiped the stem down after each pad with an Obsidian Oil saturated cloth to remove the grime and protect the stem.

I set the bowl aside and turned my attention to the stem. I sanded the stem with 320-3500 grit sanding pads and wiped the stem down after each pad with an Obsidian Oil saturated cloth to remove the grime and protect the stem.  I polished the stem with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I polished it further with Before & After Pipe Stem Polish – both fine and extra fine.

I polished the stem with micromesh sanding pads – dry sanding it with 1500-12000 grit pads. I polished it further with Before & After Pipe Stem Polish – both fine and extra fine.

This Bertram Washington, DC 80 Apple (some might call it a Prince but the bowl is not shaped right and the stem is not bent correctly for one) with a vulcanite stem is a great looking pipe now that it has been restored. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bertram 80 Straight Apple fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.13 ounces/33 grams. This older American Made Apple is a real beauty. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will set it aside and once I finish the other two pipes that Jack sent to me, I will send the lot back to him. Thanks for your time.

This Bertram Washington, DC 80 Apple (some might call it a Prince but the bowl is not shaped right and the stem is not bent correctly for one) with a vulcanite stem is a great looking pipe now that it has been restored. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bertram 80 Straight Apple fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.13 ounces/33 grams. This older American Made Apple is a real beauty. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will set it aside and once I finish the other two pipes that Jack sent to me, I will send the lot back to him. Thanks for your time.