by Steve Laug

About a year ago I visited an older pipe repair man (when I say older I mean older than me). He gave me a lot of pipe parts – stems, bases, bowl, tenons and bands. In the lot there were quite a few Bakelite bases shaped a lot like Kirsten bases. They were square and had threaded opening on the top for a screw held bowl, a threaded opening on the end for a cap and an opening for a stem of some sort. There were no complete pipes in the lot, just some pieces like those pictured below. These were rough and unpolished and seemed like the end where the cap was had been shaped and the corners on the stem end were also shaped. On Monday, August 25 after a visit with my brother Kenneth and I went to visit my contact again. This time he had more stuff that he wanted to get rid of from his parts. Once again, we received more stems and tenons. But he also put in a box of pipes that were in various states of repair or disrepair. One of those pipes was one that included the same kind of base that is shown above. I took photos of the pipe before I started working on it. The pipe was unsmoked. It had a Bakelite base, a brass end cap screw and a vulcanite stem. The bowl was also unsmoked and clean. It was held to the base with hollow screw. The bowl was a rusticated briar bowl in an apple shape. There was a vulcanite piece inserted in the base end that the stem was pressure fit on. The stem was lightly oxidized and scratched from sitting in storage. I think that once I cleaned and polished the parts and put it back together it would be a great looking pipe.

On Monday, August 25 after a visit with my brother Kenneth and I went to visit my contact again. This time he had more stuff that he wanted to get rid of from his parts. Once again, we received more stems and tenons. But he also put in a box of pipes that were in various states of repair or disrepair. One of those pipes was one that included the same kind of base that is shown above. I took photos of the pipe before I started working on it. The pipe was unsmoked. It had a Bakelite base, a brass end cap screw and a vulcanite stem. The bowl was also unsmoked and clean. It was held to the base with hollow screw. The bowl was a rusticated briar bowl in an apple shape. There was a vulcanite piece inserted in the base end that the stem was pressure fit on. The stem was lightly oxidized and scratched from sitting in storage. I think that once I cleaned and polished the parts and put it back together it would be a great looking pipe.

I took a close up photo of the bowl and rim top showing its condition. The bowl was clearly unsmoked and the screw was clean and shiny. The Bakelite shank/base is also dull and scratched. The stem shows the scratches and marks from storage and some light oxidation.

I took a close up photo of the bowl and rim top showing its condition. The bowl was clearly unsmoked and the screw was clean and shiny. The Bakelite shank/base is also dull and scratched. The stem shows the scratches and marks from storage and some light oxidation. I took the pipe apart and took photos of the pipe parts. It is a bit of an ingenuous creation with the Bakelite base forming a condensation chamber and the cap on the end allowing for clean out.

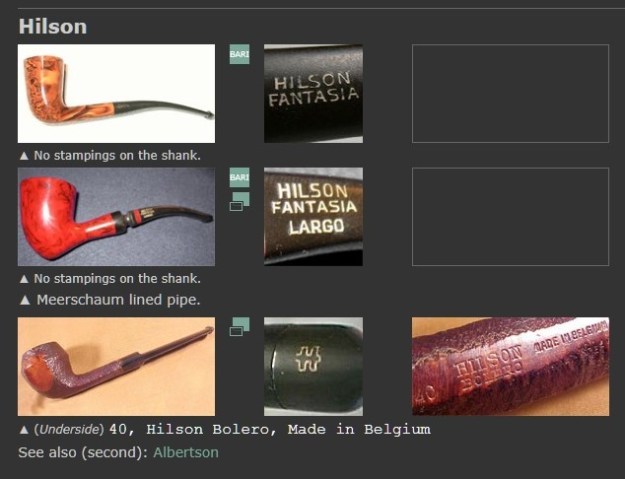

I took the pipe apart and took photos of the pipe parts. It is a bit of an ingenuous creation with the Bakelite base forming a condensation chamber and the cap on the end allowing for clean out. Before I started polishing the pipe parts I did a bit of digging on the Smoking Metal website to see if I could find anything (http://www.smokingmetal.co.uk/). There was no name to work with and no particular branding on the pipe to give direction. I went a bit deeper on the site and found one listed in “STEM OF OTHER MATERIALS & Screw thro bowl”. Here is the link to that page (http://www.smokingmetal.co.uk/pipe.php?page=88). I have also included the photos of the pipe and the description.

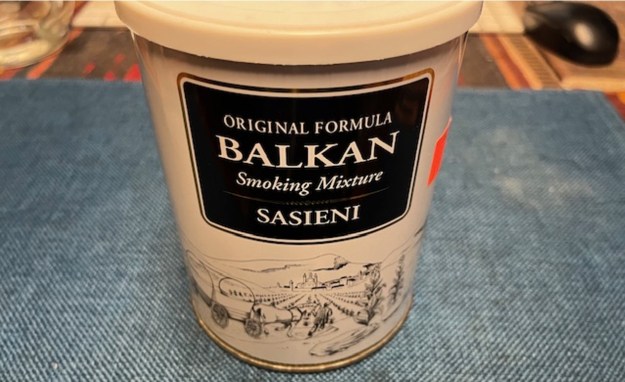

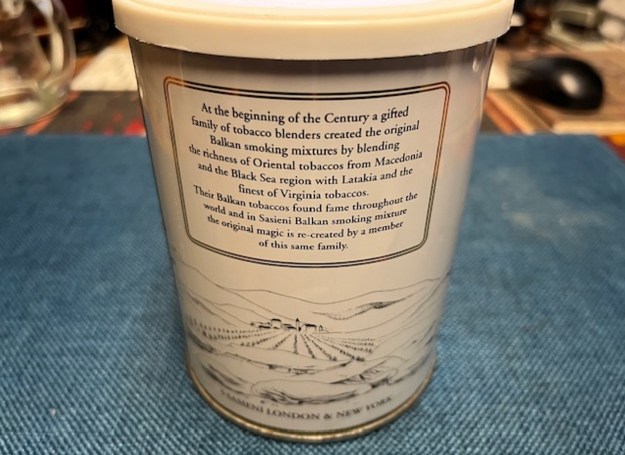

Before I started polishing the pipe parts I did a bit of digging on the Smoking Metal website to see if I could find anything (http://www.smokingmetal.co.uk/). There was no name to work with and no particular branding on the pipe to give direction. I went a bit deeper on the site and found one listed in “STEM OF OTHER MATERIALS & Screw thro bowl”. Here is the link to that page (http://www.smokingmetal.co.uk/pipe.php?page=88). I have also included the photos of the pipe and the description. Briar bowl screwed onto a black bakelite ? shank with a rubber mouthpiece. Would appear to take Kirsten bowls and similar. Front end plug unscrews to facilitate cleaning. Overall length 5 1/2 inches (142 m/m).

Briar bowl screwed onto a black bakelite ? shank with a rubber mouthpiece. Would appear to take Kirsten bowls and similar. Front end plug unscrews to facilitate cleaning. Overall length 5 1/2 inches (142 m/m).

From the photos of the pipe and the description you can see the similarities to the pipe I am working on. Compare it to the picture of the parts above. I am fairly certain that it is the same pipe.

Now it was time to work on the pipe. I wiped off the dust and debris on the bowl exterior with a damp cloth. I worked some Before & After Restoration Balm into the surface of the rusticated bowl with my finger tips and a shoe brush. I let it sit for 10 minutes and then buffed it off with a soft cloth. It looked very good.

I cleaned out the inside of the base with alcohol and pipe cleaners. I removed the dust and it was very clean. I cleaned the stem the same way.

I cleaned out the inside of the base with alcohol and pipe cleaners. I removed the dust and it was very clean. I cleaned the stem the same way. I polished the Bakelite base with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down after each pad with an Obsidian Oil soaked cloth. It started to take on a deep shine. I finished the polishing with Before & After Pipe Stem Polish both Fine and Extra Fine. I wiped it a final time with the cloth. It looked very good.

I polished the Bakelite base with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down after each pad with an Obsidian Oil soaked cloth. It started to take on a deep shine. I finished the polishing with Before & After Pipe Stem Polish both Fine and Extra Fine. I wiped it a final time with the cloth. It looked very good.

I put the shank and the brass cap back together again. I also screwed the bowl in place on the shank. It is looking very good with the clean and polished look.

I put the shank and the brass cap back together again. I also screwed the bowl in place on the shank. It is looking very good with the clean and polished look.

Now it was time to polish the stem. I polished it with micromesh sanding pads – dry sanding it with 1500-12000 grit sanding pads. I wiped it down after each pad with an Obsidian Oil cloth. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. It really looked good with the polishing.

Now it was time to polish the stem. I polished it with micromesh sanding pads – dry sanding it with 1500-12000 grit sanding pads. I wiped it down after each pad with an Obsidian Oil cloth. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. It really looked good with the polishing.

This interesting Kirsten like Bakelite/Briar pipe with a short saddle vulcanite stem looks amazing after the work on it. The briar is clean and the polished Bakelite really came alive. The rich brown stains on the bowl gave the finish a sense of depth with the polishing and waxing. The polished Bakelite base really popped. I put the it all together and butted the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bakelite/Briar Kirsten like pipe really is quite nice looking and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 46 grams/1.62 ounces. I will soon be putting this pipe on the rebornpipes store in the Various Pipe Makers section. It should make a great smoker that the next steward will enjoy. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on.

This interesting Kirsten like Bakelite/Briar pipe with a short saddle vulcanite stem looks amazing after the work on it. The briar is clean and the polished Bakelite really came alive. The rich brown stains on the bowl gave the finish a sense of depth with the polishing and waxing. The polished Bakelite base really popped. I put the it all together and butted the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bakelite/Briar Kirsten like pipe really is quite nice looking and feels great in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 46 grams/1.62 ounces. I will soon be putting this pipe on the rebornpipes store in the Various Pipe Makers section. It should make a great smoker that the next steward will enjoy. Thanks for reading this blog and my reflections on the pipe while I worked on it. It was a fun one to work on.