Blog by Steve Laug

The next pipe on the work table is one that I took in on a trade from a fellow in the Netherlands. It is a great looking smooth quarter bent Dublin. It is stamped on the left side of the shank and read Georg Jensen [over] Made in Denmark Pipes. On the right side it is stamped Dania. There is a shape number 9980 on the underside of the shank. The pipe is shaped to highlight the grain around the bowl. The finish is quite clean with just a bit of grime and oil in bowl sides. The smooth rim top is in excellent condition with some light lava near the inner edge. The inner edge is clean and sharp. The bowl has a moderate cake that I will ream out but otherwise looks very good. The vulcanite taper stem was made for a 9mm filter. There is the Georg Jensen interlocked red GJ logo on the left side of stem. There is light oxidation and calcification on the stem surface and there are tooth marks and chatter on both sides ahead of the button.

I took photos of the rim top and the stem surfaces to give a sense of the condition of the pipe. You can see the light lava on the rim top and other than that top is in good condition. There is a light cake in the bowl that I will ream to make sure the walls are in good condition. The stem photos show the oxidation, calcification, tooth marks and the chatter on both sides ahead of the button.

I took photos of the rim top and the stem surfaces to give a sense of the condition of the pipe. You can see the light lava on the rim top and other than that top is in good condition. There is a light cake in the bowl that I will ream to make sure the walls are in good condition. The stem photos show the oxidation, calcification, tooth marks and the chatter on both sides ahead of the button. I took photos of the stamping on the sides of the shank, both the left and the right sides. It is clear and readable. The stamping on the left side identifies the maker and country of origin. It reads Georg Jensen [over] Made in Denmark Pipes. On the left side of the taper stem it is stamped with an interlocked GJ in red. The stamping on the right side reads Dania which is the pipe line.

I took photos of the stamping on the sides of the shank, both the left and the right sides. It is clear and readable. The stamping on the left side identifies the maker and country of origin. It reads Georg Jensen [over] Made in Denmark Pipes. On the left side of the taper stem it is stamped with an interlocked GJ in red. The stamping on the right side reads Dania which is the pipe line.

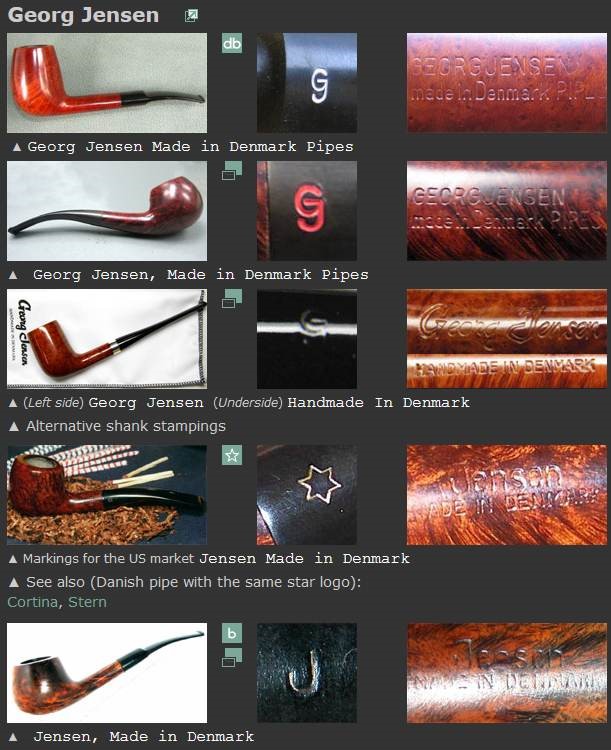

An added part of pipe restoration for me is the opportunity to gather background information on a brand and maker to add depth to the restoration. I almost always turn to Pipephil’s site first for a summary. In this case it did not let me down (http://www.pipephil.eu/logos/en/logo-g2.html#georgjensen). It has a longer listing for the Georg Jensen Brand. The stamping and logo on the one in hand is like the second pipe down in the photo below. I have included a screen capture of the section below. I have also included a copy of the side bar information that gives a brief glimpse of the brand.

An added part of pipe restoration for me is the opportunity to gather background information on a brand and maker to add depth to the restoration. I almost always turn to Pipephil’s site first for a summary. In this case it did not let me down (http://www.pipephil.eu/logos/en/logo-g2.html#georgjensen). It has a longer listing for the Georg Jensen Brand. The stamping and logo on the one in hand is like the second pipe down in the photo below. I have included a screen capture of the section below. I have also included a copy of the side bar information that gives a brief glimpse of the brand. Per Georg Jensen managed the Georg Jensen Pipe brand during 23 years and is currently (2011) active as “Tobacco Professor” at Mac Baren Tobacco Company. See also: Danets, North Dane Pipes, White Star, Goodwill

Per Georg Jensen managed the Georg Jensen Pipe brand during 23 years and is currently (2011) active as “Tobacco Professor” at Mac Baren Tobacco Company. See also: Danets, North Dane Pipes, White Star, Goodwill

I turned then to Pipedia (https://pipedia.org/wiki/Georg_Jensen) and found a short listing on Georg Jensen. I have included it below.

The Georg Jensen pipe factory was founded by Per Georg Jensen and his wife in 1954, in Kopenhagen, Denmark. Since the 80s the company is under the management of his daughter Lis, and his son with the same name, Per Georg Jensen. The company manufactured around 2,000 factory pipes per year. Among the top of the line pipes are hand carved special editions and free hands.

Top of the Line models of Georg Jensen have vulcanite or ebonite stems, factory pipes usually have acrylic stems.

Factory pipes (in increasing quality) were marked:

Danish Sand Achat / Amber Red Flame / Red Skin Sunrise / Orange extra / Starline Contrast / Bicolour / Harmon Excellent / Masterpiece

Pipes were commonly marked (in increasing quality) with: MODEL + MODEL NUMBER + “Made in Denmark”, GJ stamp in red on the stem. MODEL NUMBER + “Georg Jensen” in italic or fancy font.

Extremely rare and collectible freehands were marked with: “Straight Grain” and a number that discerns the grading from 1 (lowest) to 13 (highest).

Special edition pipes were marked with: MODEL + MODEL NUMBER + “Handmade in Denmark” + GJ stamp in white on the stem.

The factory closed down in 2001 when Per Georg Jensen (Jr) became “Tobacco Professor” for MacBaren Tobacco house.

Now, on to the restoration of this pretty Georg Jensen Filter Dublin. I began the work by reaming the pipe with a PipNet reamer and cut back the cake back to the bare briar. I scraped out what remained with a Savinelli Fitsall Pipe Knife. I sanded the walls of the bowl with a piece of dowel wrapped with 220 grit sandpaper to smooth the out. The walls looked to be in excellent condition with no checking or heat damage.

I scrubbed the inside of the mortise and shank along with the stem with alcohol, cotton swabs and pipe cleaners. The pipe was looking better than when it arrived.

I scrubbed the inside of the mortise and shank along with the stem with alcohol, cotton swabs and pipe cleaners. The pipe was looking better than when it arrived. I scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. I worked on the rim top and edge to try to remove the grime and was able to remove it.

I scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. I worked on the rim top and edge to try to remove the grime and was able to remove it.

I polished the smooth briar rim top with micromesh sanding pads – dry sanding it with 1500-12000 grit sanding pads. I wiped the bowl surface down with a damp cloth to remove the sanding dust. Once I finished the exterior of the briar looked much better and had taken on a shine.

I polished the smooth briar rim top with micromesh sanding pads – dry sanding it with 1500-12000 grit sanding pads. I wiped the bowl surface down with a damp cloth to remove the sanding dust. Once I finished the exterior of the briar looked much better and had taken on a shine.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I set the bowl aside and turned my attention to the stem. I “painted” the stem surface with the flame of a Bic lighter to lift the tooth marks. I was able to lift all of them so it could be sanded.

I set the bowl aside and turned my attention to the stem. I “painted” the stem surface with the flame of a Bic lighter to lift the tooth marks. I was able to lift all of them so it could be sanded. I wiped the stem down with Soft Scrub cleanser to remove the oxidation and the calcification on the stem. It really did a great job removing the oxidation and the stem is starting to look very good.

I wiped the stem down with Soft Scrub cleanser to remove the oxidation and the calcification on the stem. It really did a great job removing the oxidation and the stem is starting to look very good. I used the sanding pads I purchased recently – 320-3500 grit regular pads to smooth out the finish and remove the light tooth and chatter marks in the stem. I wiped the stem down with Obsidian Oil to finish the preliminary work after the 3500 grit pad.

I used the sanding pads I purchased recently – 320-3500 grit regular pads to smooth out the finish and remove the light tooth and chatter marks in the stem. I wiped the stem down with Obsidian Oil to finish the preliminary work after the 3500 grit pad. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of oil and set it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of oil and set it aside to dry.

I fit the filter stem with a new 9mm filter. The fit was perfect and the pipe was ready to be smoked by the next trustee.

I fit the filter stem with a new 9mm filter. The fit was perfect and the pipe was ready to be smoked by the next trustee. As usual at this point in the restoration process I am excited to be on the homestretch. I look forward to the final look when it is put back together, polished and waxed. I put the Georg Jensen Dania 9980 Dublin back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The grain really pops with the wax and polish. The shiny black vulcanite 9mm filter stem is a beautiful contrast to the reddish, browns of the bowl. This Georg Jensen Dania was a great pipe to spruce up. It is a very comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 47 grams/1.66 ounces. This pipe will be going on the Danish Pipe Maker section of the rebornpipes store if you are interested in adding it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.

As usual at this point in the restoration process I am excited to be on the homestretch. I look forward to the final look when it is put back together, polished and waxed. I put the Georg Jensen Dania 9980 Dublin back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The grain really pops with the wax and polish. The shiny black vulcanite 9mm filter stem is a beautiful contrast to the reddish, browns of the bowl. This Georg Jensen Dania was a great pipe to spruce up. It is a very comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 47 grams/1.66 ounces. This pipe will be going on the Danish Pipe Maker section of the rebornpipes store if you are interested in adding it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.