Blog by Steve Laug

Not too long ago I went for coffee with a friend of mine who used to own a pipe shop. He had some pipes to sell and wanted me to have a look. The first of the pipes was a pair of Peterson’s Silver Caps from 2000. These were brand new pipes – unsmoked and really never put out in his store. They were still in their original boxes. One of the boxes had the $600 price tag still intact on the end. The pipes included a 106 Billiard and a 150 Bulldog. Each pipe was boxed and included the original Peterson’s of Dublin Established 1865 Pipe Sock in the box. These pipes are both clean and unsmoked. The only issue with them was that the silver rim cap, band and P on the stem were tarnished and blackened from sitting. The Bulldog had a P-lip style stem while the Billiard had a fishtail stem with a removable adapter in place in the tenon so that it could be smoked with the Peterson’s 9mm filters that were included in the box. I took each pipe out of the box and took pictures of it to show its general condition. The Bulldog was first. You can see the finish is flawless with some nice grain around the bowl. The silver cap and band are tarnished but undamaged. Both have hallmark stamps on them so I should be able to identify the year of manufacture of the pipe. The silver P on the left side of the saddle stem is also tarnished but undamaged. When I opened the cap the bowl inside was polished and smooth. It was indeed unused. The stem was flawless and there was no oxidation or discolouration to be detected. There were no marks on the stem also showing that it was unused. The airway in the shank and the stem were clean and polished. It is stamped on the left side of the shank Peterson’s with the old forked P arched over Dublin. On the right side it has the shape number 150 and reads Made in the Republic of Ireland. The pipe is a beauty and the silver will really stand out once it is polished and cleaned.

I took each pipe out of the box and took pictures of it to show its general condition. The Bulldog was first. You can see the finish is flawless with some nice grain around the bowl. The silver cap and band are tarnished but undamaged. Both have hallmark stamps on them so I should be able to identify the year of manufacture of the pipe. The silver P on the left side of the saddle stem is also tarnished but undamaged. When I opened the cap the bowl inside was polished and smooth. It was indeed unused. The stem was flawless and there was no oxidation or discolouration to be detected. There were no marks on the stem also showing that it was unused. The airway in the shank and the stem were clean and polished. It is stamped on the left side of the shank Peterson’s with the old forked P arched over Dublin. On the right side it has the shape number 150 and reads Made in the Republic of Ireland. The pipe is a beauty and the silver will really stand out once it is polished and cleaned.

I took some close up photos of the rim cap and the stem to show the condition. You can see the tarnish on the rim cap and the deep shine on the stem. The cap also bore hallmarks that I would be better able to read when I had cleaned up the silver. The band also bore hallmarks that would be readable as well.

I took some close up photos of the rim cap and the stem to show the condition. You can see the tarnish on the rim cap and the deep shine on the stem. The cap also bore hallmarks that I would be better able to read when I had cleaned up the silver. The band also bore hallmarks that would be readable as well. The Billiard was second. You can see the finish is flawless with some nice grain around the bowl. The silver cap and band are tarnished but undamaged. Both have hallmark stamps on them so I should be able to identify the year of manufacture of the pipe. The silver P on the left side of the tapered fishtail stem is also tarnished but undamaged. When I opened the cap the bowl inside was polished and smooth. It was unused as well. The stem was flawless and there was no oxidation or discolouration to be detected. There were no marks on the stem also showing that it was unused. The airway in the shank and the stem were clean and polished. It is stamped on the left side of the shank Peterson’s with the old forked P arched over Dublin. On the right side it has the shape number 106 and reads Made in the Republic of Ireland. This pipe is a beauty as well and the silver will really stand out once it is polished and cleaned.

The Billiard was second. You can see the finish is flawless with some nice grain around the bowl. The silver cap and band are tarnished but undamaged. Both have hallmark stamps on them so I should be able to identify the year of manufacture of the pipe. The silver P on the left side of the tapered fishtail stem is also tarnished but undamaged. When I opened the cap the bowl inside was polished and smooth. It was unused as well. The stem was flawless and there was no oxidation or discolouration to be detected. There were no marks on the stem also showing that it was unused. The airway in the shank and the stem were clean and polished. It is stamped on the left side of the shank Peterson’s with the old forked P arched over Dublin. On the right side it has the shape number 106 and reads Made in the Republic of Ireland. This pipe is a beauty as well and the silver will really stand out once it is polished and cleaned.

I took some close up photos of the rim cap and the stem on the billiard to show the condition. You can see the tarnish on the rim cap and the deep shine on the stem. The cap also bore hallmarks that I would be better able to read when I had cleaned up the silver. The band also bore hallmarks that would be readable as well.

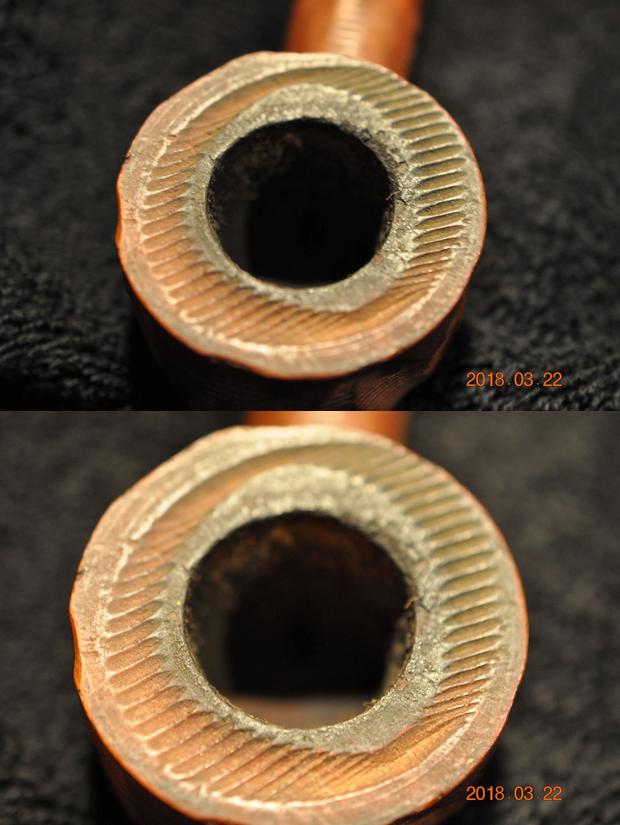

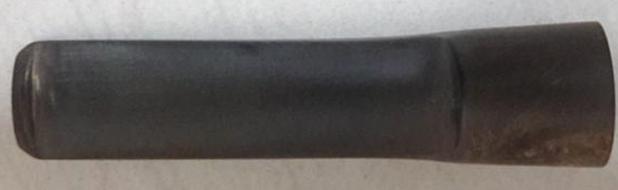

I took some close up photos of the rim cap and the stem on the billiard to show the condition. You can see the tarnish on the rim cap and the deep shine on the stem. The cap also bore hallmarks that I would be better able to read when I had cleaned up the silver. The band also bore hallmarks that would be readable as well. The Billiard came with an adapter in the tenon that was removable allowing the pipe to be smoked with or without the 9MM Absorba Filters. The pictures below show the adaptor in and out of the tenon.

The Billiard came with an adapter in the tenon that was removable allowing the pipe to be smoked with or without the 9MM Absorba Filters. The pictures below show the adaptor in and out of the tenon.  I polished the silver on both pipes with a jeweler’s polishing cloth that removes tarnish and protects silver. I worked over the bands and caps on both pipes as well as the silver P on the stems.

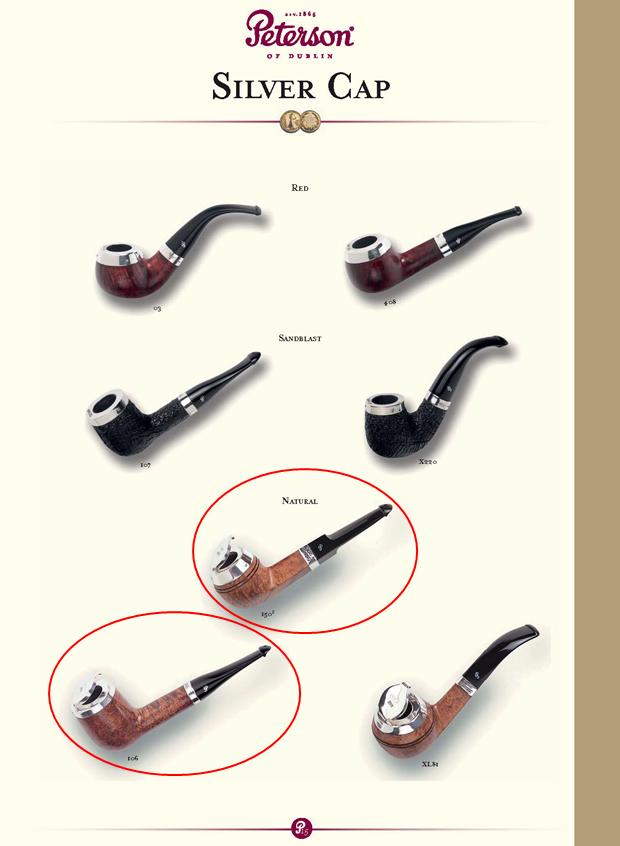

I polished the silver on both pipes with a jeweler’s polishing cloth that removes tarnish and protects silver. I worked over the bands and caps on both pipes as well as the silver P on the stems. I did some hunting for information on the pipes in a Peterson’s Catalogue I have on rebornpipes (https://rebornpipes.com/2015/05/15/a-beautiful-peterson-of-dublin-pipe-catalogue/). I have copied several pages from the catalogue for use here. The first page shows the Silver Cap series. The two pipes in this blog are Natural Finished pipes – shape number 150 and number 106. I have circled both of them in the picture below.

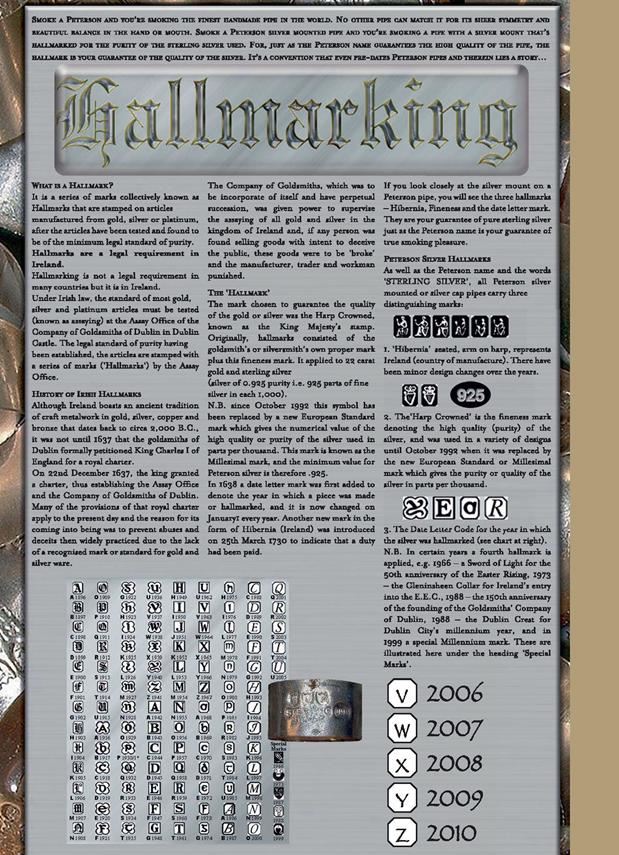

I did some hunting for information on the pipes in a Peterson’s Catalogue I have on rebornpipes (https://rebornpipes.com/2015/05/15/a-beautiful-peterson-of-dublin-pipe-catalogue/). I have copied several pages from the catalogue for use here. The first page shows the Silver Cap series. The two pipes in this blog are Natural Finished pipes – shape number 150 and number 106. I have circled both of them in the picture below. The second page I have included is a hallmark chart below that helps date the pipes. Both pipes have the standard Peterson’s Hallmarks. On both pipes each hallmark is the same. The first mark is the Hibernia which identifies the country of origin as Ireland. The second mark is the Crowned Harp mark is the fineness mark which denotes the quality of the silver as 925. The third mark is the date mark which in this case is the cursive Q identifying the year of manufacture as 2000.

The second page I have included is a hallmark chart below that helps date the pipes. Both pipes have the standard Peterson’s Hallmarks. On both pipes each hallmark is the same. The first mark is the Hibernia which identifies the country of origin as Ireland. The second mark is the Crowned Harp mark is the fineness mark which denotes the quality of the silver as 925. The third mark is the date mark which in this case is the cursive Q identifying the year of manufacture as 2000. Here are photos of the finished pipes. The first is the Dublin Silver Cap 150 Bulldog. The first picture shows the box end with the shape number and the pipe shop price of the pipe new. The dimensions of the pipe are: Length: 5 1/2 inches, Height: 2 inches (including the cap) Diameter of the Bowl: 1 ¼ inches, Diameter of the Chamber: 3/4 inches. This is a beautiful pipe and will be going on the rebornpipes store. If you are interested in adding it to your collection have a look there.

Here are photos of the finished pipes. The first is the Dublin Silver Cap 150 Bulldog. The first picture shows the box end with the shape number and the pipe shop price of the pipe new. The dimensions of the pipe are: Length: 5 1/2 inches, Height: 2 inches (including the cap) Diameter of the Bowl: 1 ¼ inches, Diameter of the Chamber: 3/4 inches. This is a beautiful pipe and will be going on the rebornpipes store. If you are interested in adding it to your collection have a look there.

The second pipe is the Dublin Silver Cap 106 Billiard. The first picture shows the box end with the shape number and the pipe shop price of the pipe new. The dimensions of the pipe are: Length: 6 inches, Height: 2 1/8 inches (including the cap) Diameter of the Bowl: 1 1/2 inches, Diameter of the Chamber: 3/4 inches. This is another beautiful pipe and it will also be going on the rebornpipes store. If you are interested in adding it to your collection have a look there.

The second pipe is the Dublin Silver Cap 106 Billiard. The first picture shows the box end with the shape number and the pipe shop price of the pipe new. The dimensions of the pipe are: Length: 6 inches, Height: 2 1/8 inches (including the cap) Diameter of the Bowl: 1 1/2 inches, Diameter of the Chamber: 3/4 inches. This is another beautiful pipe and it will also be going on the rebornpipes store. If you are interested in adding it to your collection have a look there.

Both of these are beautiful pipes and will be worthy additions to a Peterson’s Collector’s rack. They have stunning grain and polished silver. The combination looks really good with the black of the stem and silver inset P on the left side of the stems. They are new old stock (NOS) and have never been smoked or even handled much since 2000. If you would like to add one of both to your collection let me know via email to slaug@uniserve.com or send me a message on Facebook. Thanks for looking.

Both of these are beautiful pipes and will be worthy additions to a Peterson’s Collector’s rack. They have stunning grain and polished silver. The combination looks really good with the black of the stem and silver inset P on the left side of the stems. They are new old stock (NOS) and have never been smoked or even handled much since 2000. If you would like to add one of both to your collection let me know via email to slaug@uniserve.com or send me a message on Facebook. Thanks for looking.