Blog by Steve Laug

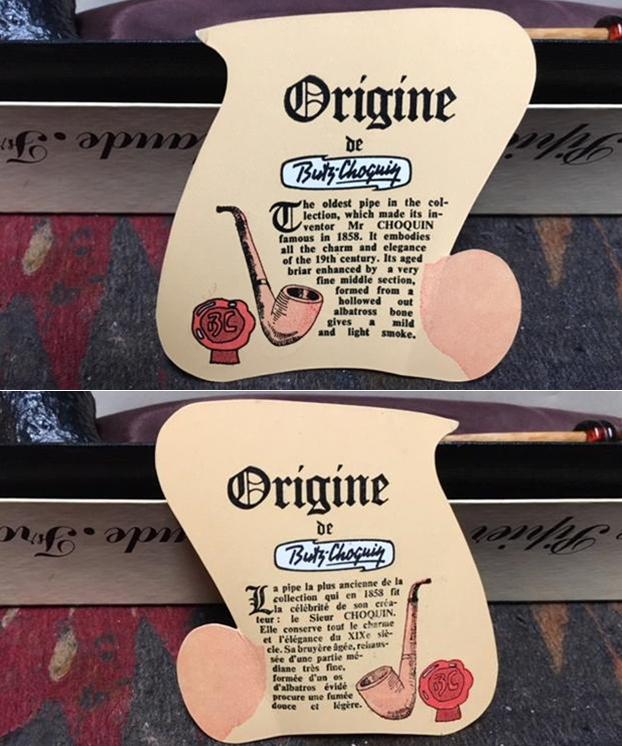

A few weeks ago I received an email from a reader of the blog living in Edmonton, Alberta, Canada about some pipes that he was selling. There were some Bari’s, Stanwell’s, Svendborgs, and a Butz-Choquin. He sent me pictures of the lot and I was hooked. He is primarily a cigarette smoker so these pipes are relatively clean. He said that the Butz-Choquin had hardly been smoked. We did an etransfer and the pipes were on their way to me. They arrived in Vancouver in a couple of days (quite different from the ones I pick up in Eastern Canada or in the US). I opened the box and looked through the eight pipes I purchased and the pipe rack that he included. I was pleased with the purchase. I decided to work on the BC one first. I took photos of my own discovery of what the Butz-Choquin pipe looked like. I took photos of the box to give an idea of the process of discover. When I opened the box there was an interesting looking pipe – not very big but one that I had wanted to see for a long time. It also had a tag in the box that I took a photo of as well. I took a photo of the card that was in the box with the pipe. It can be seen in the next two photos with English on the one side and the other side in French. It reads: Origine de Butz Choquin. The oldest pipe in the collection, which made its inventor, Mr. Choquin famous in 1858. It embodies all the charm and elegance of the 19th century. Its aged briar enhanced by a very fine middle section, formed from a hollowed out albatross bone gives a mild and light smoke.

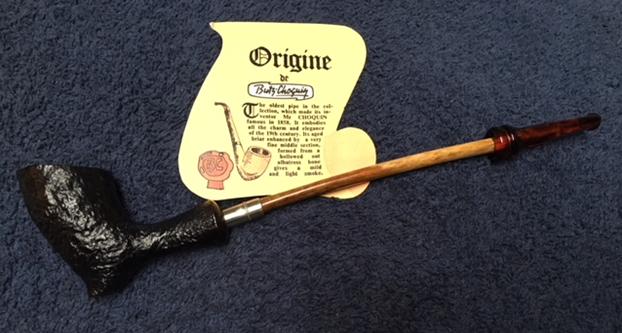

I took a photo of the card that was in the box with the pipe. It can be seen in the next two photos with English on the one side and the other side in French. It reads: Origine de Butz Choquin. The oldest pipe in the collection, which made its inventor, Mr. Choquin famous in 1858. It embodies all the charm and elegance of the 19th century. Its aged briar enhanced by a very fine middle section, formed from a hollowed out albatross bone gives a mild and light smoke. The fellow who sent it to me had packed it in a pipe bag. It was not original but it did the job. I took the pipe out of the bag and took photos of it from different angles to give an idea of the uniqueness and beauty of this pipe. The pipe is 7 ½ inches long, 1 ¾ inches tall, the diameter of the bowl is 1 1/8 inches and the chamber diameter is 5/8 inches. The sandblast finish is a little dusty but in very good condition and really quite attractive. The shape of the bowl has a foot on the bottom, almost like a clay tavern pipe and sits easily on the foot. The albatross bone is in great shape. It has a silver coloured end cap on it that is a bit tarnished. The stem is acrylic with Tortoiseshell amber or Bakelite look to it and it is in excellent condition. The bowl is lightly smoked and not even broken in; my guess is that maybe one of two bowls were smoked in it. There is still raw briar in the bottom third of the bowl.

The fellow who sent it to me had packed it in a pipe bag. It was not original but it did the job. I took the pipe out of the bag and took photos of it from different angles to give an idea of the uniqueness and beauty of this pipe. The pipe is 7 ½ inches long, 1 ¾ inches tall, the diameter of the bowl is 1 1/8 inches and the chamber diameter is 5/8 inches. The sandblast finish is a little dusty but in very good condition and really quite attractive. The shape of the bowl has a foot on the bottom, almost like a clay tavern pipe and sits easily on the foot. The albatross bone is in great shape. It has a silver coloured end cap on it that is a bit tarnished. The stem is acrylic with Tortoiseshell amber or Bakelite look to it and it is in excellent condition. The bowl is lightly smoked and not even broken in; my guess is that maybe one of two bowls were smoked in it. There is still raw briar in the bottom third of the bowl.

I took some close up photos of the underside of the shank to capture the stamping there. It reads Butz-Choquin over MAVA with the number 025 on the shank end. As the pipe is turned it is also stamped on the underside St. Claude France.

I took some close up photos of the underside of the shank to capture the stamping there. It reads Butz-Choquin over MAVA with the number 025 on the shank end. As the pipe is turned it is also stamped on the underside St. Claude France. I took a photo of the end of the shank to show brass ring inset in the end to strengthen the briar with the long stem and the metal end cap on the stem.

I took a photo of the end of the shank to show brass ring inset in the end to strengthen the briar with the long stem and the metal end cap on the stem. I took the pipe apart and took pictures of the pieces. The first one below shows the bowl. You can see the raw briar in the bottom of the bowl and the slight darkening to the rest of the bowl. It is quite clean with a slight aromatic smell. I took photos of the albatross wing bone and the acrylic stem that was permanently attached to the bone.

I took the pipe apart and took pictures of the pieces. The first one below shows the bowl. You can see the raw briar in the bottom of the bowl and the slight darkening to the rest of the bowl. It is quite clean with a slight aromatic smell. I took photos of the albatross wing bone and the acrylic stem that was permanently attached to the bone. I took some close up photos of the stem to show its general condition. It is hard to tell from the photos but the stem has a Tortoiseshell pattern in the reds of the acrylic. There was some light tooth chatter on both sides of the stem at the button – nothing to deep or damaging. I also took a close up of the metal end cap on the shank end of the wing bone. It is tarnished where it is inserted in the shank but otherwise just dull.

I took some close up photos of the stem to show its general condition. It is hard to tell from the photos but the stem has a Tortoiseshell pattern in the reds of the acrylic. There was some light tooth chatter on both sides of the stem at the button – nothing to deep or damaging. I also took a close up of the metal end cap on the shank end of the wing bone. It is tarnished where it is inserted in the shank but otherwise just dull. It was time to do a bit of reading about this pipe. The one I have is a little different from the one that is described in the quote below. It is not a billiard shape but rather a cutty shaped pipe. The extended stem on the one I have appears to be true bone rather than the white acrylic that is shown in the photos that accompany the article. The stem itself is reddish, amber or Bakelite colour rather than the black as noted. It is very light weight and actually quite delicate looking.

It was time to do a bit of reading about this pipe. The one I have is a little different from the one that is described in the quote below. It is not a billiard shape but rather a cutty shaped pipe. The extended stem on the one I have appears to be true bone rather than the white acrylic that is shown in the photos that accompany the article. The stem itself is reddish, amber or Bakelite colour rather than the black as noted. It is very light weight and actually quite delicate looking.

On the GQ Tobaccos site I found some interesting information about the brand and this particular pipe. The link is; http://www.gqtobaccos.com/pipes/butz-choquin-origine-sandblasted/. I quote in full from the website.

The Butz Choquin Origine pipes represent one of the first designs created by Jean-Baptiste Choquin and Gustave Butz in the mid 1800’s. The Original Origine made use of an albatross wing bone, for the long, extended stem. The deep billiard style bowl, sports a slight foot on the base and is finished sandblasted with a brown stain. The stem extenders is made from Acrylic (faux bone effect) and fitted with a nickel spigot and matching band near the mouthpiece. The black acrylic mouthpiece is curved, making this demi warden/reading pipe ideal for hands free smoking. The spigot fitting makes the use of the common 9mm filter impossible, but it can be used without easily.

Butz Choquin started life back as a tobacconist in Metz, during 1850’s run by Jean-Baptiste Choquin. One of Jeans longest serving members of staff was a young Gustave Butz who had a desire to not only sell pipes, but also create them. In 1958 Gustave married Jeans eldest Daughter Marie and become an actual part of the family.

The pair set about creating a unique and distinct pipe, the now world famous “BC Origine” was first created in same year. This flat bottomed bowl was fitted with a long albatross bone shank and dual silver rings. To this day this pipe is one of the most iconic from Butz Choquin range, although sadly it no longer has the natural shank, replaced with acrylic.

Over the years the pair created a large range of pipes which not only sold within their own, but exported all over Europe and further field. The popularity of the pairs pipes grew and grew and by the 1951 the Berrod-Regad company brought out the family company. Production continued in Metz until 2002 when the whole operation was shifted to the mountain community St Claude. This picturesque village had been the centre of the worlds Briar trade for generations and the local craftsmen continued to produce high quality pipes.

To this day Butz Choquin are renowned for their desire of making more interesting and left field colour schemes. Using high quality briar, original equipment and colourful dyes/acrylic rods.

With that information I turned to the relative simple refurbish on this pipe. Looking at the bowl it is very different from the photos of the ones that I have seen online. The extension is not the white acrylic and the plumbing for holding it all together is very different from the current photos. It makes me wonder the age of the pipe. I wrote to the fellow who sold it to me to see if he remembers when he purchased it… the verdict is out on this one for now.

I started my clean up by working some Before & After Restoration Balm into nooks and crannies of the sandblast finish on the bowl and shank with my fingers and a horsehair shoe brush. I want the product to go deep into the finish because it works to clean, enliven and protect the briar. Once I was confident that it was deeply worked into the blast I wiped it off and buffed it with a soft cloth to polish it. The pipe really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. The sandblast finish shows the character of the grain on the underlying briar in the photos below. It is a really nice piece of wood and the shape is quite unique in terms of the finished look.

I decided to use the Before & After Restoration Balm on the extended shank. If it was bone then it would enliven it and add protection to it. If it is acrylic the same would be true. Whatever the material is it is an oval piece with a slight bend in it. It is set in the stem and in the metal end cap. I rubbed it in by hand and buffed it off with a soft cloth.

I decided to use the Before & After Restoration Balm on the extended shank. If it was bone then it would enliven it and add protection to it. If it is acrylic the same would be true. Whatever the material is it is an oval piece with a slight bend in it. It is set in the stem and in the metal end cap. I rubbed it in by hand and buffed it off with a soft cloth.  I polished the end cap with micromesh sanding pads – using 1500-12000 grit pads to bring a real sheen to the metal. It is probably nickel as it does not have any silver standard stamps on the cap. I polished it with a jeweler’s cloth as a finishing touch. It looks far better after cleaning.

I polished the end cap with micromesh sanding pads – using 1500-12000 grit pads to bring a real sheen to the metal. It is probably nickel as it does not have any silver standard stamps on the cap. I polished it with a jeweler’s cloth as a finishing touch. It looks far better after cleaning. I cleaned out the mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners to remove the lingering aromatic smell and any tars or oils that had collected in those spots. It was pretty clean so it did not take too much to clean those spots.

I cleaned out the mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners to remove the lingering aromatic smell and any tars or oils that had collected in those spots. It was pretty clean so it did not take too much to clean those spots.  The bowl and shank extension were clean and polished. I set the bowl aside and worked on the stem. I sanded out the tooth chatter with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I gave it a final coat of oil and set it aside to dry.

The bowl and shank extension were clean and polished. I set the bowl aside and worked on the stem. I sanded out the tooth chatter with micromesh sanding pads – wet sanding it with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I gave it a final coat of oil and set it aside to dry.

I carefully polished bowl and the stem with Blue Diamond to polish out the remaining small scratches. I gave the bowl, shank extension and the stem multiple coats of Conservator’s Wax and buffed the bowl separately with a clean buffing pad to raise the shine. I hand buffed the extended shank and pipe with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The dark brown stain worked really well with the mottled “wing bone” extension and the Tortoiseshell acrylic stem. The finished pipe has a truly unique look to it that I had not seen before. I really like the looks of it. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 7 1/2 inches, Height: 1 3/4 inches, Outer diameter of the bowl: 1 1/8 inches, Chamber diameter: 5/8 inches. This unique is staying with me as an addition to my collection. I look forward to loading it with some rich, aged McClellands 5100 and enjoying a quiet and reflective bowl. Hopefully this refurbishment was worth your time to read. Thank you for walking with me as I worked over this beauty.

I carefully polished bowl and the stem with Blue Diamond to polish out the remaining small scratches. I gave the bowl, shank extension and the stem multiple coats of Conservator’s Wax and buffed the bowl separately with a clean buffing pad to raise the shine. I hand buffed the extended shank and pipe with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The dark brown stain worked really well with the mottled “wing bone” extension and the Tortoiseshell acrylic stem. The finished pipe has a truly unique look to it that I had not seen before. I really like the looks of it. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 7 1/2 inches, Height: 1 3/4 inches, Outer diameter of the bowl: 1 1/8 inches, Chamber diameter: 5/8 inches. This unique is staying with me as an addition to my collection. I look forward to loading it with some rich, aged McClellands 5100 and enjoying a quiet and reflective bowl. Hopefully this refurbishment was worth your time to read. Thank you for walking with me as I worked over this beauty.