By Al Jones

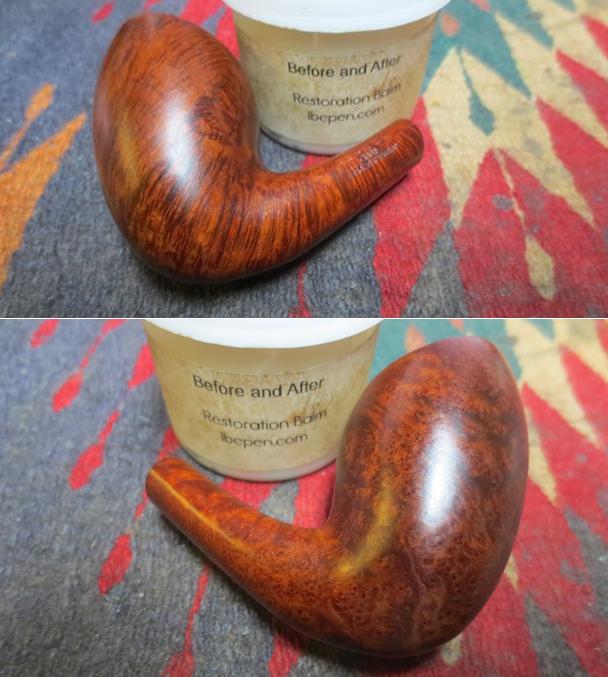

I don’t purchase many Charatans because most of them are simply too large and I’m more of a “classic shape” guy versus freehands. To be honest, I also don’t look forward to dealing with the stamped “CP” stem logo, which are usually very lightly stamped. This shape 08 bulldog caught my attention as it is one of only two Charatan bulldog shapes, the other being the 109 (which is listed as a Rhodesian). This one is stamped a “Special” but like many Charatans, it seems undergraded to my eye.

I can date the pipe to being made from between 1955 and 1960. The circled “L” logo stamp was first used in 1955 and all Charatans received double-comfort stems starting in 1960.

Another plus for this pipe, in my collection is the size – despite being a solid Group 4 (or maybe even a Group 5), it only weighs 38 grams. That is diminutive by Charatan standards.

Beside the oxidized logo, this one had other challenges. The diamond shank bulldog stem had several facets that I typically don’t see on a bulldog stem, including the flat sides of the stem. The top of the bowl had some rim darkening as well.

The bowl had numerous marks around the bowl, including these peck marks.

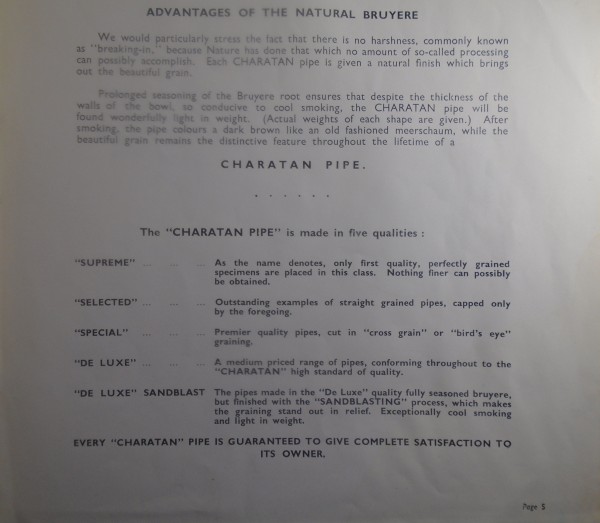

The pipe had a very slight cake and after reaming, I found the bowl was in great shape. I used an electric iron on high to steam out most of the marks. As I thought, the peck marks on the front of the bowl proved problematic. I was able to remove a few marks in that area and slightly diminished the others, but they could not be removed completely.

I used 6,000 and 8,000 grade micromesh on the bowl top to remove a lot of the darkening. To remove it any further would have required topping the pipe and restaining it. I thought it had greater value keeping it as original as possible.

I removed the outer layer of oxidation on the stem with 400 and 800 grit paper, then moving thru the 1,500 and 2,000 grades. Finally, 8,000 and 12,000 grades micromesh were used. Working around the faintly stamped logo was of course a big challenge. The stem was then buffed with White Diamond and Meguiars Plastic polish.

Below is the completed pipe.

Update Jan 17, 2018:

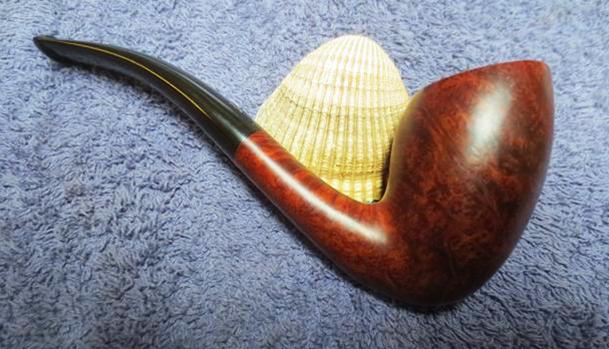

We are fortunate at the PipesMagazine.com forum to have the participation of Ken Barnes. Ken is the son of Colonel Kenneth Barnes, who was a managing director for Charatan. Ken himself started working at Charatan when he was 14 years old and is a wealth of information on that brand as well as James Upshall. Ken added this information about the pipe brand and these two catalog pages.

The Special quality was around in 1951 as shown, and this was the largest size of the Bulldog shape no. 8

I think that the mouthpiece is hand-cut. I have learnt that the clue is that the saddle ‘step’ is sharp and 90 degrees rather than curved (a photo of the bite opening would confirm this).

I was thinking that there may be someone out there who could etch the Cp a little deeper and then fill the stamp with Crayola white wax and wipe away the surplus. I think that Reubin Charatan first used Crayola wax for the logos in 1910. I do know that the Crayola company was founded in 1903.