Blog entry by Al Jones

I’ve worked on a few Yello Bole pipes owned by a forum friend, but until now, I hadn’t found one of my own. I spied this one at a Pennsylvania flea market that I visit a few times per year. One vendor always has some older Kaywoodie. Last week, I found this Yello Bole in the case.

The pipe was definitely well loved, but the stem was nearly mint. I thought with the cake removed, the briar would also be in good shape. From the stamping and a comment on the Kaywoodie forums, I believe the pipe was made between 1937 and 1955.

The scoop/stinger apparatus came out easily and without it, the stem fit snugly into the shank.

I reamed the bowl and found an interior in great shape. I used some distilled water and a little alcohol to remove the tar buildup on the bowl top. The pipe was then soaked with sea salt and alcohol. There were a few spots of lifted stain on the bowl (from its previous use/life). I used some Feiblings Medium Brown stain, at full strength, to touch up those areas.

I put a dab of grease on the stem logo (which seems pretty durable) and soaked it in a mild solution of Oxy-Clean. There was a slight tooth crease on top of the stem, but it lifted nicely with a flame and was removed in the cleaning process. The stem was then mounted on the pipe and mild oxidation removed with 800>1500 and 2000 grit wet paper. I then moved to the 8000 and 12000 grade micromesh papers. The last step was to buff the stem with White Diamond and then Meguiars Plastic polish. I waxed the bowl exterior with some Paragon wax.

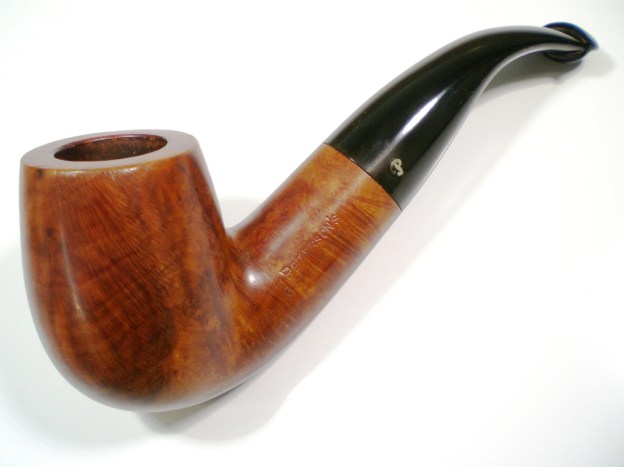

Here is the finished pipe, ready for use.