Blog by Andrew Selking

I remember back in basic training my Drill Sergeant always used to say, “Men, ugly women need love too”. That was my initial thought when I first saw this Kaywoodie Fine Line pot. The stem was under-clocked, the varnished finish was uneven, the rim had some damage, and it just looked kind of dull. On the plus side, the stem was in decent shape and my fondness for Kaywoodies provided the motivation to help it live up to its potential. As you can see, the stem was noticeably under-clocked.

As you can see, the stem was noticeably under-clocked. Fortunately I have a tool for that.

Fortunately I have a tool for that. After directly heating the stinger with my heat gun, I gently turned it back to its original position and set it by running the end of the stem under cold water. This was the result.

After directly heating the stinger with my heat gun, I gently turned it back to its original position and set it by running the end of the stem under cold water. This was the result.

I soaked the bowl overnight in the alcohol bath then reamed it with my Castleford reamer.

I soaked the bowl overnight in the alcohol bath then reamed it with my Castleford reamer. While the bowl soaked, I gave the stem a bath in Oxyclean. I make it a practice to use the Oxyclean and a fuzzy stick (that’s the politically correct term for a pipe cleaner intended for crafts rather than cleaning pipes) to get as much gunk out while it’s still soft. This is what the fuzzy stick looked like after the first pass.

While the bowl soaked, I gave the stem a bath in Oxyclean. I make it a practice to use the Oxyclean and a fuzzy stick (that’s the politically correct term for a pipe cleaner intended for crafts rather than cleaning pipes) to get as much gunk out while it’s still soft. This is what the fuzzy stick looked like after the first pass. Normally a fuzzy stick without a lot of tar and tobacco is cause for celebration, but I suspected the stinger merely kept the gunk in the shank. When cleaning Kaywoodies I have to deviate from my normal process of retorting the stem and bowl separately, since the rubber tube doesn’t fit inside the shank very well. Here is the pipe ready for retort.

Normally a fuzzy stick without a lot of tar and tobacco is cause for celebration, but I suspected the stinger merely kept the gunk in the shank. When cleaning Kaywoodies I have to deviate from my normal process of retorting the stem and bowl separately, since the rubber tube doesn’t fit inside the shank very well. Here is the pipe ready for retort. After the first retort.

After the first retort. I did the retort two more times. This is what was hiding inside the shank.

I did the retort two more times. This is what was hiding inside the shank. After scrubbing the solids out with a brush dipped in alcohol, I switched to q-tips dipped in alcohol. As you can see, it took a good amount to get it clean.

After scrubbing the solids out with a brush dipped in alcohol, I switched to q-tips dipped in alcohol. As you can see, it took a good amount to get it clean. The boiling alcohol loosened up the tar in the stem. It turned out my original guess was correct, the stinger kept the stem relatively clean.

The boiling alcohol loosened up the tar in the stem. It turned out my original guess was correct, the stinger kept the stem relatively clean.

With the inside of the pipe clean, I turned my attention to the outside of the pipe. The first thing I wanted to do was get rid of the remaining varnish. I used acetone and 0000 steel wool.

With the inside of the pipe clean, I turned my attention to the outside of the pipe. The first thing I wanted to do was get rid of the remaining varnish. I used acetone and 0000 steel wool. Next I topped the bowl to eliminate the rim damage. I used a piece of glass with 400 grit sand paper.

Next I topped the bowl to eliminate the rim damage. I used a piece of glass with 400 grit sand paper. After topping the bowl I used Pimo Pipe Supply medium walnut stain to cover up the couple of fills.

After topping the bowl I used Pimo Pipe Supply medium walnut stain to cover up the couple of fills. While I was at it, I polished the aluminum insert in the shank with 0000 steel wool.

While I was at it, I polished the aluminum insert in the shank with 0000 steel wool.

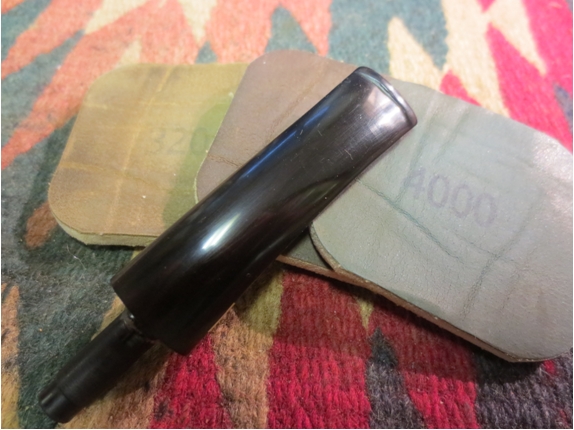

With the bowl in good shape, I started work on the stem. I used 400 grit wet/dry sand paper with water to remove the minor tooth marks and oxidation. I then used 1500-2400 grit micro mesh pads with water. Next I re-assembled the pipe with a rubber washer between the stem and shank to prevent rounding the end of the stem. I finished the stem with micro mesh pads, 3200-12,000 grit, followed by white diamond and carnauba wax using the rotary tool on low speed.

With the bowl in good shape, I started work on the stem. I used 400 grit wet/dry sand paper with water to remove the minor tooth marks and oxidation. I then used 1500-2400 grit micro mesh pads with water. Next I re-assembled the pipe with a rubber washer between the stem and shank to prevent rounding the end of the stem. I finished the stem with micro mesh pads, 3200-12,000 grit, followed by white diamond and carnauba wax using the rotary tool on low speed.  A light coat of Halcyon II on the bowl and here’s the result.

A light coat of Halcyon II on the bowl and here’s the result.

I think the old girl cleaned up nicely. She may not be a shiny pipe, but she is a sturdy pipe. Thanks for looking.

I think the old girl cleaned up nicely. She may not be a shiny pipe, but she is a sturdy pipe. Thanks for looking.