Blog by Steve Laug

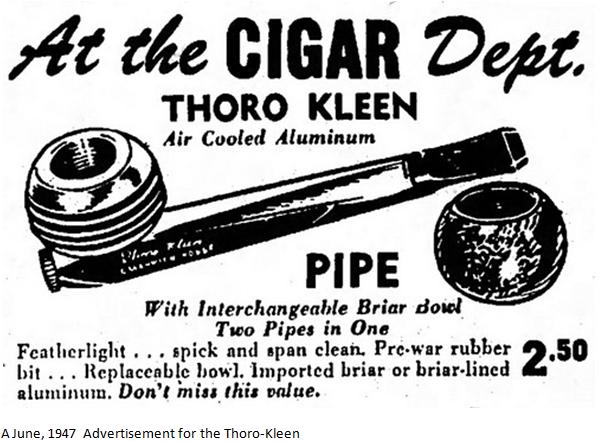

For some crazy reason I have always liked odd pipes – pipes that pushed the envelope in the search for a cool dry smoke. Together they are alike a museum display of odd and inventive contraptions. When my brother sent me this metal pipe it certainly fit the category of the unusual. The design and shape to me bring back memories of watching the Jetsons on Saturday morning cartoons. The metallic spaceship like pipe encourages those connections for me. It has a streamlined metal shank with an end cap on one end and a stem on the other. It flows. The bowl is a finned affair with a briar insert. I think the idea was to make an indestructible easy to clean pipe. The fact that many remain on the market speaks to the indestructibility of the pipe but as for easy to clean well to me the jury is still out. Evidently the pipe originally came with two bowls – a choice of looks. The first like the one shown in the advertisement about was metal finned affair with a briar insert. The second was a briar bowl of various shapes. Both bowls were held to the shank with a hollowed out screw that served as the airway from the bottom of the bowl to the shank. The stem and end cap come off for ease of cleaning. The body of the pipe can be hexagonal, square (Thoro-Kleen only seen in this shape) or circular in cross section. The unmarked version tends to be regarded as the COMET, all the others being stamped with a name. The Smoking Metal website shows variations on the brand. Follow the link and you can see photos and information. http://www.smokingmetal.co.uk/pipe.php?page=99

Evidently the pipe originally came with two bowls – a choice of looks. The first like the one shown in the advertisement about was metal finned affair with a briar insert. The second was a briar bowl of various shapes. Both bowls were held to the shank with a hollowed out screw that served as the airway from the bottom of the bowl to the shank. The stem and end cap come off for ease of cleaning. The body of the pipe can be hexagonal, square (Thoro-Kleen only seen in this shape) or circular in cross section. The unmarked version tends to be regarded as the COMET, all the others being stamped with a name. The Smoking Metal website shows variations on the brand. Follow the link and you can see photos and information. http://www.smokingmetal.co.uk/pipe.php?page=99

According to Pipedia the Greenwich House Thoro-Kleen was a metal pipe system from the same family as the Roybrooke, Comet, and Original Gridiron pipes, and parts from all are believed to be interchangeable. The pipes were sold by the Greenwich House Corporation, located in 1947 at 939-M 8th Avenue, N.Y. 19, N.Y… The pipe set sold for $2.50 in 1947. https://pipedia.org/wiki/Thoro-Kleen

From all of this I learned that the probable year of the pipe’s manufacture was 1947. It was a pretty sweet little pipe that definitely wore its age well. I did a bit more research as I wanted to find out what the packaging and the additional bowl looked like as the one I had, came only with the attached bowl. I found some photos that show the original packaging and have included them below.

I also found a picture of the pipe taken apart showing all of the pieces. This was an important picture for me as it helped to understand how to take apart the bowl and the end cap. The one I was working on was so dirty and caked that I could not see the screw in the bottom of the bowl and the end cap was stuck. I was not sure if it was pressure fit like a Kirsten or threaded. This answered those questions for me. Once I took mine apart I found that it did not have a paper filter but rather a metal stinger.

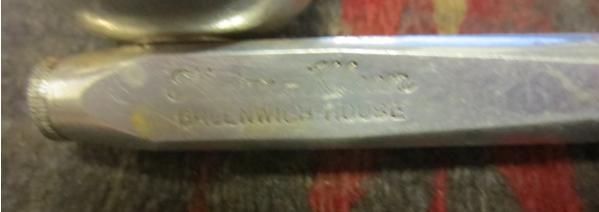

I also found a picture of the pipe taken apart showing all of the pieces. This was an important picture for me as it helped to understand how to take apart the bowl and the end cap. The one I was working on was so dirty and caked that I could not see the screw in the bottom of the bowl and the end cap was stuck. I was not sure if it was pressure fit like a Kirsten or threaded. This answered those questions for me. Once I took mine apart I found that it did not have a paper filter but rather a metal stinger. I took the following photos of the pipe to record the condition it was in when I started. Part of the fun for me is to work on a pipe and then compare the finished pipe to where it was when I started the process. The aluminum bowl and base were oxidized and dull. The stamping on the side of the shank was readable but lightly stamped in the middle portion. It read Thoro-Kleen in flowing script over Greenwich House.

I took the following photos of the pipe to record the condition it was in when I started. Part of the fun for me is to work on a pipe and then compare the finished pipe to where it was when I started the process. The aluminum bowl and base were oxidized and dull. The stamping on the side of the shank was readable but lightly stamped in the middle portion. It read Thoro-Kleen in flowing script over Greenwich House. The end cap had a slot that fit a standard 25 cents piece that could be used to open it. In this case it was stuck and I could not turn it. The stem was oxidized and had many tooth dents on the top and bottom sides. The bowl was badly caked to the point that no air could get from the bowl to the base. I was unable to see the bottom of the bowl and know what held it to the base. The briar bowl insert was damaged and had burn marks toward the bowl front.

The end cap had a slot that fit a standard 25 cents piece that could be used to open it. In this case it was stuck and I could not turn it. The stem was oxidized and had many tooth dents on the top and bottom sides. The bowl was badly caked to the point that no air could get from the bowl to the base. I was unable to see the bottom of the bowl and know what held it to the base. The briar bowl insert was damaged and had burn marks toward the bowl front.

I took some close up photos of the bowl and stem to show the condition they were in when I began the restoration.

I took some close up photos of the bowl and stem to show the condition they were in when I began the restoration.

In order to take the pipe apart I reamed the cake enough to be able to get to the screw in the bottom of the bowl. The funny thing is that while I was turning the handle on the PipNet pipe reamer the bowl twisted free of the base and I was able to take it apart. At this point the pipe looked like the photo below. I was not able to remove the end cap as it was still stuck.

In order to take the pipe apart I reamed the cake enough to be able to get to the screw in the bottom of the bowl. The funny thing is that while I was turning the handle on the PipNet pipe reamer the bowl twisted free of the base and I was able to take it apart. At this point the pipe looked like the photo below. I was not able to remove the end cap as it was still stuck. I finished reaming the bowl with the PipNet reamer and took the cake back to bare briar.

I finished reaming the bowl with the PipNet reamer and took the cake back to bare briar.

I heated the end of the pipe with the flame from the lighter to loosen and soften the tars that held the threads tightly in place. After several failed attempts to turn it and then reheating it I was able to turn if free of the base with a pair of padded pliers. You can see from the photos below the thick dark substance that filled the end cap and the base.

I heated the end of the pipe with the flame from the lighter to loosen and soften the tars that held the threads tightly in place. After several failed attempts to turn it and then reheating it I was able to turn if free of the base with a pair of padded pliers. You can see from the photos below the thick dark substance that filled the end cap and the base.

I used a dental pick to begin to pick out the sludge on the inside of the cap and the base. You can see from the photo the amount of dried hard material that came out and this was only the beginning.

I used a dental pick to begin to pick out the sludge on the inside of the cap and the base. You can see from the photo the amount of dried hard material that came out and this was only the beginning. The inside of the base was lined with hardened material. I plugged the tube with cotton pads and ran alcohol through the base to begin to soften the material. It took a lot of work to loosen it and the cotton pads came out darkened.

The inside of the base was lined with hardened material. I plugged the tube with cotton pads and ran alcohol through the base to begin to soften the material. It took a lot of work to loosen it and the cotton pads came out darkened. I lightly topped the bowl to remove the damaged area and the burned area.

I lightly topped the bowl to remove the damaged area and the burned area.

I removed the stinger from the stem and cleaned the airway with fluffy and bristle pipe cleaners, cotton swabs and alcohol. I sanded the stem with 220 grit sandpaper to remove the oxidation and minimize the tooth marks.

I removed the stinger from the stem and cleaned the airway with fluffy and bristle pipe cleaners, cotton swabs and alcohol. I sanded the stem with 220 grit sandpaper to remove the oxidation and minimize the tooth marks. I used thick folded bristle pipe cleaners to run through the base to remove the grime and oils that were left behind once I had scraped it clean.

I used thick folded bristle pipe cleaners to run through the base to remove the grime and oils that were left behind once I had scraped it clean. With the first level of cleaning done on the pipe I laid out the parts and took a picture. I also took a photo of the stamping on the shank now that I had cleaned it up enough for it to show more clearly.

With the first level of cleaning done on the pipe I laid out the parts and took a picture. I also took a photo of the stamping on the shank now that I had cleaned it up enough for it to show more clearly.

I scrubbed the fins and grooves on the bowl with alcohol and cotton swabs.

I scrubbed the fins and grooves on the bowl with alcohol and cotton swabs. I scrubbed out the inside of the screw, end cap, threads and the inside of the metal bowl with pipe cleaners, cotton swabs and alcohol.

I scrubbed out the inside of the screw, end cap, threads and the inside of the metal bowl with pipe cleaners, cotton swabs and alcohol. Once the end cap was clean and the inside of the base was clean I greased the threads on the cap with Vaseline and turned it into the base.

Once the end cap was clean and the inside of the base was clean I greased the threads on the cap with Vaseline and turned it into the base. I polished all of the aluminum parts of the pipe with Meguiar’s Scratch X2.0 to remove some of the scratches and oxidation.

I polished all of the aluminum parts of the pipe with Meguiar’s Scratch X2.0 to remove some of the scratches and oxidation. With the bowl and shank finished I put the pipe back together minus the stem. I put the briar bowl in the metal bowl and turned the screw into the base.

With the bowl and shank finished I put the pipe back together minus the stem. I put the briar bowl in the metal bowl and turned the screw into the base. I set the bowl and base aside and worked on the stem. I cleaned up the edge of the button on the stem with needle files to give it more of a sharp definition and remove the tooth marks.

I set the bowl and base aside and worked on the stem. I cleaned up the edge of the button on the stem with needle files to give it more of a sharp definition and remove the tooth marks. I sanded the file marks with 220 grit sandpaper and further cleaned up the stem.

I sanded the file marks with 220 grit sandpaper and further cleaned up the stem.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and then gave it a coat of Obsidian Oil. I dry sanded with 3200-4000 grit pads and gave it another coat of oil. I finished by sanding it with 6000-12000 grit pads and gave it a final coat of the oil and let it dry.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and then gave it a coat of Obsidian Oil. I dry sanded with 3200-4000 grit pads and gave it another coat of oil. I finished by sanding it with 6000-12000 grit pads and gave it a final coat of the oil and let it dry.

I buffed the stem with Blue Diamond on the wheel and then gave it several coats of carnauba wax. I buffed it with a clean buff and then by hand with a microfibre cloth. I gave the base and bowl a coat of Conservator’s Wax and hand buffed it with a cloth. The finished pipe is shown in the photos below. I can’t help but saying at this point – “Meet George Jetson…” Thanks for looking.

I buffed the stem with Blue Diamond on the wheel and then gave it several coats of carnauba wax. I buffed it with a clean buff and then by hand with a microfibre cloth. I gave the base and bowl a coat of Conservator’s Wax and hand buffed it with a cloth. The finished pipe is shown in the photos below. I can’t help but saying at this point – “Meet George Jetson…” Thanks for looking.

Pingback: This Greenwich House Antique Imported Briar Crowned Pot Turned into a Nightmare | rebornpipes

So i have been reading your blog now for around a year and you sir have some amazing write-ups!!!!!

i have been working on 3 different kirstens off and on now for about 3 months or more and love it!!!

Have also been working on a few falcons and am having a great time!!!

I have reciently come into a thoro kleen and am haveing a good time with it aswell as another thoro kleen looking pipe….

I love smoking metal and will probably be moving some of my briars to make room for more lol!!!

i have reciently picked up a small wood working lathe and have turned down a bowl for a falcon out of oak…

Smokes well and will only get better!!!

thanks for some awesome write ups!!!

i would also like to see if i can get some more info on the other thoro kleen looking pipe i have if tou can get any or know any info on it

LikeLike

Take a look at the Smoking metal website http://smokingmetal.co.uk/ if you have not already found it, it is amazing the amount of information that is there. Send a write up on your work and I will post it on the blog. Welcome Jason

LikeLike

Will do!!!

that would be awesome man!!!

ill start some write ups as i go!!

LikeLike

Found!!!!

It would appear to be a luminiumcraft!!!

Thanks man!!!

What an awesome wedsight!!!

LikeLike

It is one my favourite go to sites

LikeLike

If Flash Gordon smoked a pipe…. ;-D

LikeLike

Great write up in this interesting pipe, Steve. Being from NY, I am always amazed by how many pipe manufacturers and distributors were in the state.

LikeLike

Beautiful job, Steve — and a fascinating piece of history. How does the screw thread and assembly compare to Kirsten – is there any chance a Kirsten bowl would fit (without the metal bowl, of course)?

LikeLike

Hmm, good thought Dallas. The screw holding the bowl is designed the same I need to check the threads. But even if the threads don’t match I may be able to use the bowls interchangeably

LikeLike