by Steve Laug

The next pipe I have chosen to work on is a smooth finished, well patinaed Peterson’s African Block Meerschaum pipe. This one is a Bent Meerschaum pipe in a classic Peterson’s Bent Billiard shape. The rim top is flumed in the style of the 60s and 70s. Jeff and I are unclear where we picked this one up. Our best guess was we found it during a pipe hunt in November, 2024 somewhere along the Oregon Coast. This rich butterscotch and golden coloured patina on the bowl and shank adds a touch of depth to the pipe. The pipe was dirty with grime ground into the finish on the pipe. It was thick and oily feeling to touch. The contrast on the meer of the rich colouration/patina on the bowl and shank with the flumed top made a beautiful pipe. It had nicks and chips in the outer edge of the bowl. The inner edge looked very good. The bowl had a moderate cake and there was lava on the rim top and inner edge of the bowl. The Sterling Silver ferrule is oxidized and dirty. It is stamped Peterson’s [over] Dublin followed by Sterling [over] Silver. On the underside are three hallmark stamps – 1. Seated Hibernia (Ireland) 2. The Harp (symbol for the silver quality) 3. The upper-case italic letter “E” for the date of the pipe. The stem was in quite good condition with minimal oxidation, minor debris in the edge of the button and light tooth chatter on the top and underside on and near the button. I took photos of the pipe before I started my cleanup work. They tell the story and give a glimpse of the pipe.

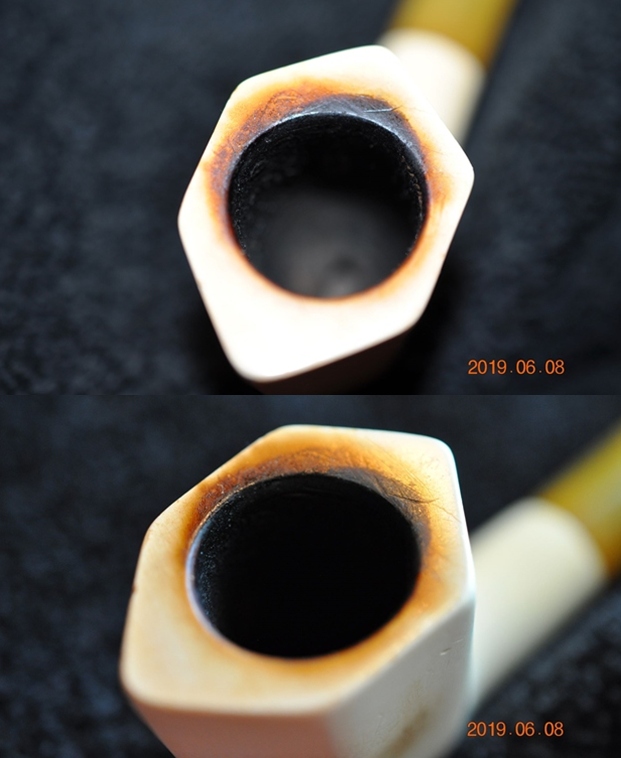

I took photos of the rim top and stem to show the general condition of the pipe. The bowl is moderately caked and the rim top and edges have lava overflowing on to them. The stem is dirty, lightly oxidized and has light tooth marks on the top and underside near the button.

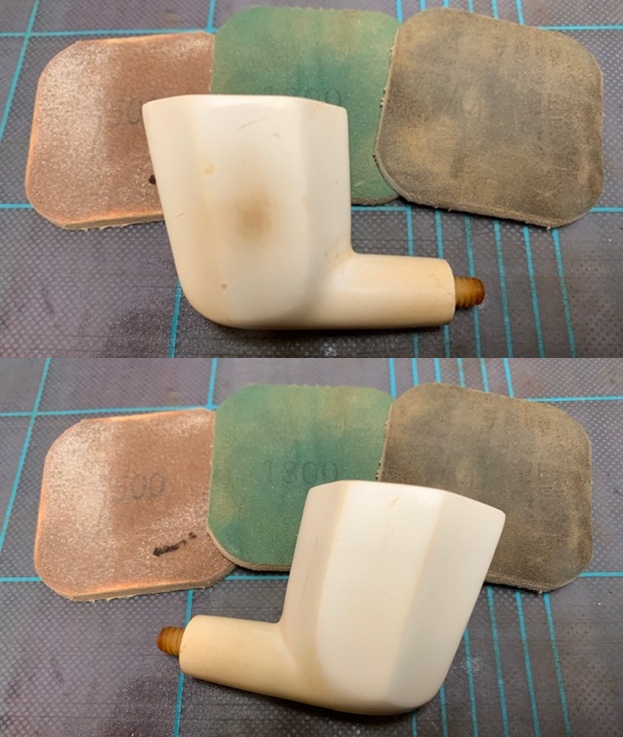

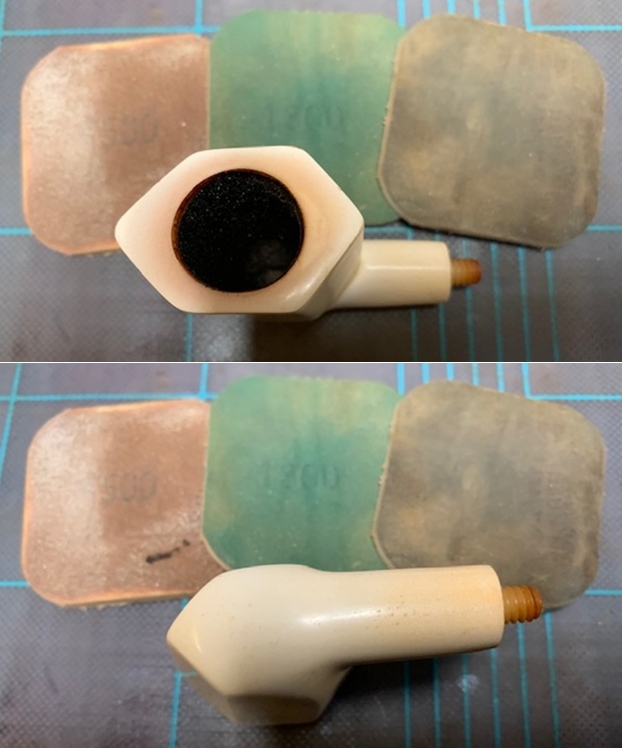

I took photos of the rim top and stem to show the general condition of the pipe. The bowl is moderately caked and the rim top and edges have lava overflowing on to them. The stem is dirty, lightly oxidized and has light tooth marks on the top and underside near the button. I took photos of the Sterling Silver ferrule to show the stamping around it. You can see that it reads as noted above. I did not capture the hallmarks on the underside. I removed the stem from the shank and took a photo of the parts of the pipe to give a sense of the proportion of the pipe.

I took photos of the Sterling Silver ferrule to show the stamping around it. You can see that it reads as noted above. I did not capture the hallmarks on the underside. I removed the stem from the shank and took a photo of the parts of the pipe to give a sense of the proportion of the pipe.

I took some time to remind myself of the provenance of these Peterson’s Dublin Meerschaum pipes. I am pretty sure the pipe was made by the Laxey Pipe Ltd. on the Isle of Man for Peterson’s in Ireland (https://pipedia.org/wiki/Laxey_Pipes_Ltd). I quote from the Pipedia article in full:

I took some time to remind myself of the provenance of these Peterson’s Dublin Meerschaum pipes. I am pretty sure the pipe was made by the Laxey Pipe Ltd. on the Isle of Man for Peterson’s in Ireland (https://pipedia.org/wiki/Laxey_Pipes_Ltd). I quote from the Pipedia article in full:

Laxey Pipe Ltd. resided in a historical 19th century four-storey Man stone building at The Quay, Old Laxey, Isle of Man, which thankfully has been preserved. The company specialized in the production of Meerschaum Pipes using the Meerschaum mined by the Tanganyika Meerschaum Corporation in the Amboseli basin in Tanganyika (since 1964 part of the United Republic of Tanzania). Please note: you may often find names like “Manx Pipes Ltd.”, “Man Pipe Co.” and others more, but there is no indication of another Isle of Man pipe producer other than Laxey Pipe Ltd. at any time!

Laxey Pipe Ltd. marketed own brands like “Manxpipe”, “Manxman”, “Manxland” e.c. Names like “John Bull”, “White Knight” (unwaxed), “Domino” (black, or lined) indicated some shapes / colours of Laxey’s own series. The stems either showed the astronomical sign for “male” or “man” (circle + arrow), or the crest of the Isle of Man, the 3-legged X in a circle. Manxpipes and Laxey’s other brands were available through pipe retailers in general, but also were sold (mainly) to tourists through their own shop in Laxey.

Furthermore Laxey Pipe Ltd. manufactured the meer bowls for Peterson, Barling, Nørding and others from the later 1960’s until 2001. Man Pipe e.g. was a brand distributed by Comoy’s. The bowls usually showed no nomenclature indicating the orderer. “Genuine Block Meerschaum” was engraved frequently. Often, just the stems were different, while bowls were the same.

Supply of meer from East Africa run out (Kenya / Tanzania exhausted, Somalia inaccessible), and thus the last Laxey meers were supplied to trade in May, 2001. Laxey Pipe Ltd. tried to survive continuing with briar pipes – mainly in the Danish style -, but to no success. It closed down business in July, 2002.

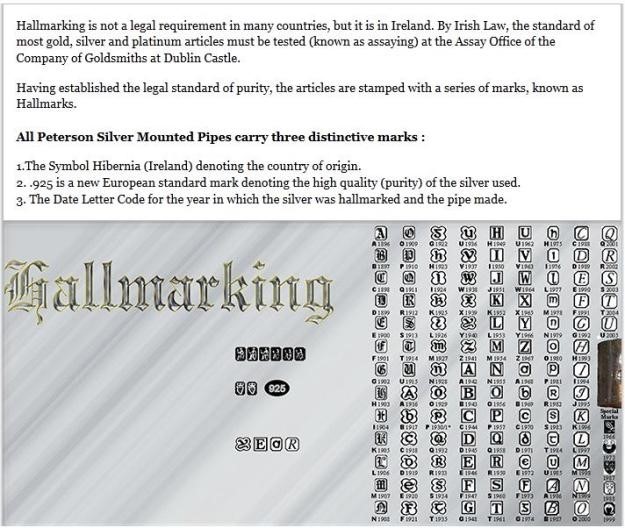

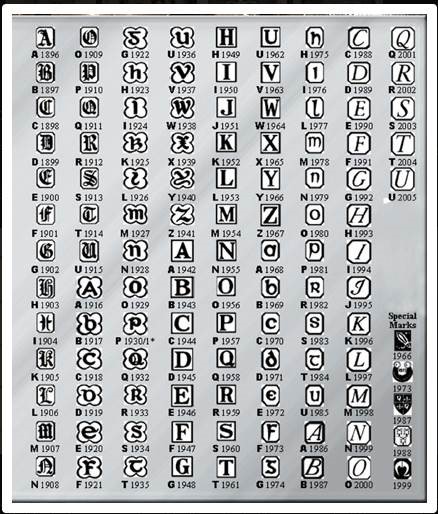

As noted above the silver is stamped Peterson’s [over] Dublin followed by Sterling [over] Silver. On the underside are three hallmark stamps – 1. Seated Hibernia (Ireland) 2. The Harp (symbol for the silver quality) 3. The upper case letter “E” for the date of the pipe. I have included the Peterson’s Hallmark chart below as it is a very helpful tool that I have used repeatedly to date my Peterson pipes. I found a larger photo of the letter section of the above chart. The letter stamp is a upper case italic “E” which dates the pipe to 1990.

I found a larger photo of the letter section of the above chart. The letter stamp is a upper case italic “E” which dates the pipe to 1990.  I know that the pipe was made on the Isle of Man by Laxey Pipe Ltd. out of African Meerschaum. It was made for export for Peterson’s of Dublin. From the hallmarks on the silver I know that the pipe (or at least the silver) was made in 1990. The flumed top on the bowl seems to make it older and maybe it is but the silver is definitely from 1990. That was as much as I could figure out.

I know that the pipe was made on the Isle of Man by Laxey Pipe Ltd. out of African Meerschaum. It was made for export for Peterson’s of Dublin. From the hallmarks on the silver I know that the pipe (or at least the silver) was made in 1990. The flumed top on the bowl seems to make it older and maybe it is but the silver is definitely from 1990. That was as much as I could figure out.

I reamed the bowl with a PipNet reamer and cleaned the reaming up with a Savinelli Fitsall Pipe Knife. I sanded the walls smooth with some 220 grit sandpaper wrapped around a piece of dowel. It looked much better. It was smooth to touch. I scraped the rim top with the edge of the Savinelli Fitsall to remove the lava build up.

I cleaned out the stinky smelling tobacco oils and tars in the shank and the airway in the stem. I used 99% isopropyl alcohol, cotton swabs and pipe cleaners and was able to remove the debris and the stench.

I cleaned out the stinky smelling tobacco oils and tars in the shank and the airway in the stem. I used 99% isopropyl alcohol, cotton swabs and pipe cleaners and was able to remove the debris and the stench. I scrubbed the exterior of the bowl with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the inside of the bowl as well to remove more of the oils and build up there. I rinsed it off with warm running water and dried it with a soft towel. When I dried it off it was dull and a bit lifeless looking. The finish was spotty so I gave it a quick buff with a cotton cloth. It looked much better and the rim top looked clean.

I scrubbed the exterior of the bowl with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the inside of the bowl as well to remove more of the oils and build up there. I rinsed it off with warm running water and dried it with a soft towel. When I dried it off it was dull and a bit lifeless looking. The finish was spotty so I gave it a quick buff with a cotton cloth. It looked much better and the rim top looked clean.

I touched up the nicks on the rim top and outer edge with a black stain pen. I had decided to leave them and not sand or remove them. It blended them in much better.

I touched up the nicks on the rim top and outer edge with a black stain pen. I had decided to leave them and not sand or remove them. It blended them in much better. I gave the meer a quick buff and then polished the Sterling Silver ferrule with a jeweller’s cloth to shine and slow down the process of oxidation. The ferrule really looks good even with a few small dents in the surface remaining. It has quite a nice sheen.

I gave the meer a quick buff and then polished the Sterling Silver ferrule with a jeweller’s cloth to shine and slow down the process of oxidation. The ferrule really looks good even with a few small dents in the surface remaining. It has quite a nice sheen.

I polished the bowl on the buffer with Blue Diamond polish and hand buffed it with a microfibre cloth to further polish it. I gave it multiple coats of Clapham’s Beeswax/Carnauba Wax and once it dried I had buffed it once again and gave it a quick buff with a clean buffing pad.

I polished the bowl on the buffer with Blue Diamond polish and hand buffed it with a microfibre cloth to further polish it. I gave it multiple coats of Clapham’s Beeswax/Carnauba Wax and once it dried I had buffed it once again and gave it a quick buff with a clean buffing pad.

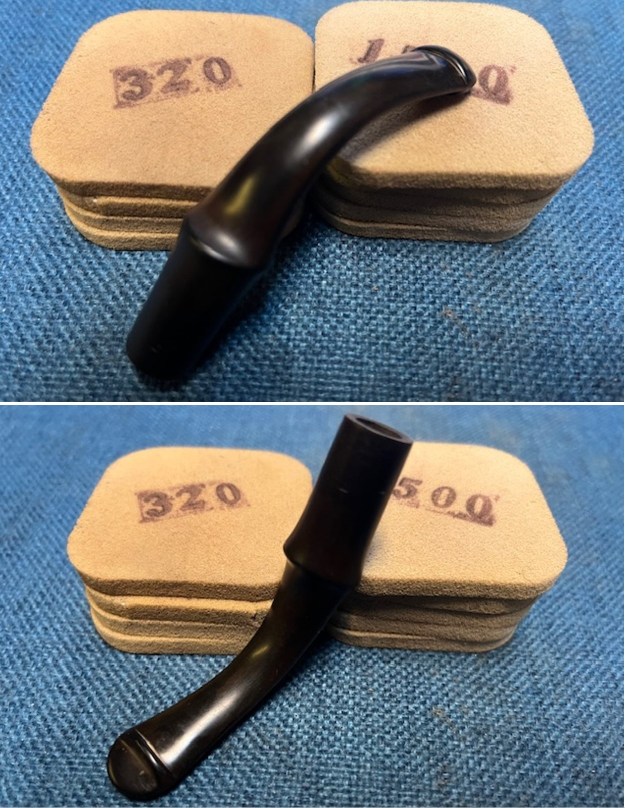

I set the bowl aside and turned to work on the stem. I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down after each pad with Obsidian Oil. It really began to take on a shine.

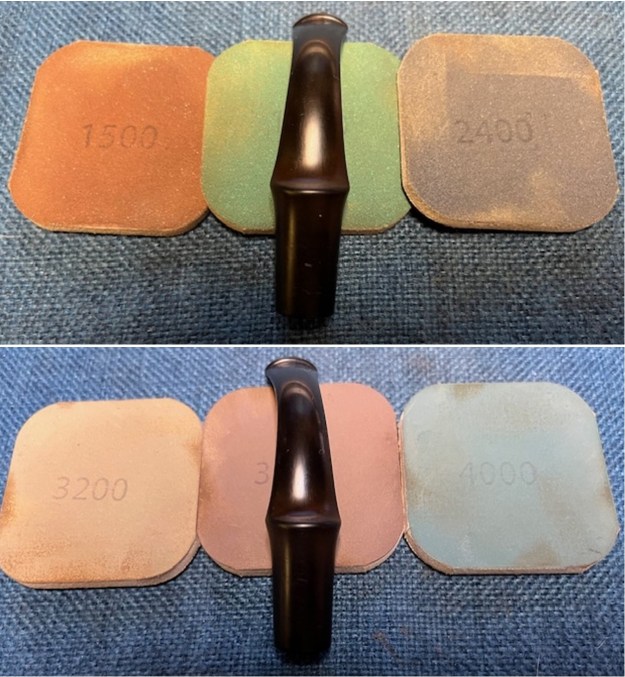

I set the bowl aside and turned to work on the stem. I sanded the stem with 320-3500 grit sanding pads. I wiped the stem down after each pad with Obsidian Oil. It really began to take on a shine. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I wiped the stem down a final time with Obsidian Oil once again and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I wiped the stem down a final time with Obsidian Oil once again and set it aside to dry.

As usual at this point in the restoration process I am excited to be on the homestretch. I look forward to the final look when it is put back together, polished and waxed. I put the bowl and stem of this Peterson’s Meerschaum back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the meerschaum and the vulcanite. I gave the bowl multiple coats of Clapham’s Beeswax/Carnauba Wax mixture and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The meerschaum has a rich glow with the wax and polish. The shiny black vulcanite stem is a beautiful contrast to the rich patina of the bowl and the polished silver ferrule. This Peterson’s meerschaum was made by the Laxey Pipe Ltd. on the Isle of Mann. The heavily patinaed finish on this pipe made it another fun pipe to work. It really is a quite stunning pipe whose shape and finish make it stand out. The thick/chubby shank makes it a very comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 59 grams/2.08 ounces. It is a beautiful pipe and one that will be on the Irish Pipe Makers Section of the rebornpipes store soon. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

As usual at this point in the restoration process I am excited to be on the homestretch. I look forward to the final look when it is put back together, polished and waxed. I put the bowl and stem of this Peterson’s Meerschaum back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the meerschaum and the vulcanite. I gave the bowl multiple coats of Clapham’s Beeswax/Carnauba Wax mixture and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The meerschaum has a rich glow with the wax and polish. The shiny black vulcanite stem is a beautiful contrast to the rich patina of the bowl and the polished silver ferrule. This Peterson’s meerschaum was made by the Laxey Pipe Ltd. on the Isle of Mann. The heavily patinaed finish on this pipe made it another fun pipe to work. It really is a quite stunning pipe whose shape and finish make it stand out. The thick/chubby shank makes it a very comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 59 grams/2.08 ounces. It is a beautiful pipe and one that will be on the Irish Pipe Makers Section of the rebornpipes store soon. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.