Blog by Steve Laug

In a recent gift box of pipes there was a billiard that had a replacement stem. The stem did not fit correctly and when it was rotated in any other way but the one it did not fit and showed light between the shank and stem. The diameter of the shank and that of the stem did not match either and the shoulders on the stem were rounded – one of my pet peeves. The pipe is stamped with gold on the left side of the shank The Albany Pipe. On the right side it is gold stamped Made in England. On the bottom of the shank it is gold stamped 17 and Fieldcraft in script.

The finish was natural – no stain and had begun to pick up a patina of age. The stamping was clear but the gold was faded and missing in some parts. The rim was dirty and also damaged on the outer edge and had some deep scratches in the top. The stem was not original. The bowl had a light cake and looked like someone had reamed it recently.

The finish was natural – no stain and had begun to pick up a patina of age. The stamping was clear but the gold was faded and missing in some parts. The rim was dirty and also damaged on the outer edge and had some deep scratches in the top. The stem was not original. The bowl had a light cake and looked like someone had reamed it recently.

I took a few close-up pictures of the rim and the stamping to give a clear picture of the state of the pipe when I brought it to the work table. You can also see the poor fit of the replacement stem in the photos as well.

I took a few close-up pictures of the rim and the stamping to give a clear picture of the state of the pipe when I brought it to the work table. You can also see the poor fit of the replacement stem in the photos as well.

The brand is one that I am unfamiliar with though in the back of my mind I have a memory of seeing it somewhere listed as a second line of a major English brand. I just cannot find it now. Does anyone have any ideas regarding the maker? I have looked in WMTP and on PipePhil and Pipedia and found nothing so far. I like knowing some of the history of the brands I restore so I am still digging on this one.

The brand is one that I am unfamiliar with though in the back of my mind I have a memory of seeing it somewhere listed as a second line of a major English brand. I just cannot find it now. Does anyone have any ideas regarding the maker? I have looked in WMTP and on PipePhil and Pipedia and found nothing so far. I like knowing some of the history of the brands I restore so I am still digging on this one.

One suggestion in response to a post I made on Smokers Forums was from flatticus (Chris) who wrote the following: “Steve, I think The Albany Pipe must be the tobacconist (there was The Albany Pipe Hospital circa 1920?) and Fieldcraft must be the brand of the pipe. There was another Fieldcraft marked for Frederick Tranter Pipe Shop in Bath, England which came up on eBay some years back, unfortunately too long ago to link properly. I can’t find a thing (trademarks, old ads, what have you) mentioning the Fieldcraft name in relation to pipes, but Tranter is still in business. I wonder if someone there would know who used to make their pipes. They were bought out by Havana House, but only about 4 years ago, so you may get lucky.”

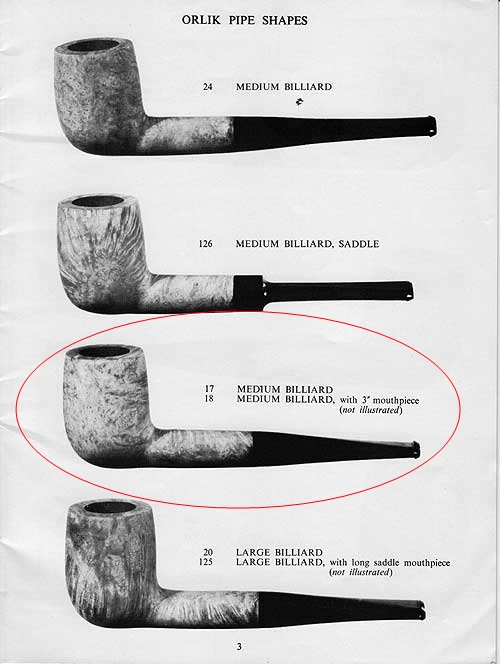

Thanks Chris I will keep looking. I did a bit more digging on PipePhil’s site and looked at the major English brands and sub-brands. The Made in England stamping looks much like that on Orlik Pipes. The shape number 17 also fits one shown in the Orlik Catalogue on Chris Keene’s Pipe pages. I removed the stem and looked through my can of stems to find one that would work better for this billiard bowl. Two options came to the front. The first is shown in the photo below next to the replacement stem that came on the pipe. It is a saddle stem that could have worked but the tenon was too small for a snug fit in the shank.

I removed the stem and looked through my can of stems to find one that would work better for this billiard bowl. Two options came to the front. The first is shown in the photo below next to the replacement stem that came on the pipe. It is a saddle stem that could have worked but the tenon was too small for a snug fit in the shank. The second stem I chose was a fat taper stem that had a tenon that was a little too large. I decided to use that one. I used a Dremel with a sanding drum to reduce the tenon enough that I could get a snug fit.

The second stem I chose was a fat taper stem that had a tenon that was a little too large. I decided to use that one. I used a Dremel with a sanding drum to reduce the tenon enough that I could get a snug fit. The next four photos show the pipe with the new stem. It has a slight bend in it that looks dapper on the bowl. There was light oxidation on the stem and tooth marks on the top and underside of the stem next to the button. Other than that the stem was in great shape. It was also slightly larger in diameter than the shank and would need to be fit properly.

The next four photos show the pipe with the new stem. It has a slight bend in it that looks dapper on the bowl. There was light oxidation on the stem and tooth marks on the top and underside of the stem next to the button. Other than that the stem was in great shape. It was also slightly larger in diameter than the shank and would need to be fit properly.

I decided to clean up the bowl before working on the fit of the stem. I lightly topped the bowl to remove the damage to the surface of the rim. I also scraped the remaining cake out of the bowl with a PipeNet pipe reamer.

I decided to clean up the bowl before working on the fit of the stem. I lightly topped the bowl to remove the damage to the surface of the rim. I also scraped the remaining cake out of the bowl with a PipeNet pipe reamer.

With the bowl cleaned I put the stem back on the shank and worked on the fit of the stem at the junction of the two. I sanded the stem and lightly sanded the shank, being careful of the stamping to clean up the transition. Because the bowl did not have a stain coat and was natural briar I figured this would be easy to blend in later when I worked on the finish. I used 220 grit sandpaper and medium and fine grit sanding sponges to blend the transition.

With the bowl cleaned I put the stem back on the shank and worked on the fit of the stem at the junction of the two. I sanded the stem and lightly sanded the shank, being careful of the stamping to clean up the transition. Because the bowl did not have a stain coat and was natural briar I figured this would be easy to blend in later when I worked on the finish. I used 220 grit sandpaper and medium and fine grit sanding sponges to blend the transition.

I took several close-up photos of the transition to show the finished fit of the stem and shank. They also show the gold stamping on the bowl.

I took several close-up photos of the transition to show the finished fit of the stem and shank. They also show the gold stamping on the bowl.

I wiped down the bowl with acetone on cotton pads. I did not worry too much about the gold stamping as I have some rub and buff that I could use to redo the gold once I cleaned up the pipe.

I wiped down the bowl with acetone on cotton pads. I did not worry too much about the gold stamping as I have some rub and buff that I could use to redo the gold once I cleaned up the pipe.

I sanded the stem and worked out the tooth marks with 220 grit sandpaper and then with medium and fine grit sanding sponges. I followed that with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. I continue to use Obsidian Oil in between each set of three pads.

I sanded the stem and worked out the tooth marks with 220 grit sandpaper and then with medium and fine grit sanding sponges. I followed that with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12,000 grit pads. I continue to use Obsidian Oil in between each set of three pads.

I buffed the stem with White Diamond and then gave it several coats of carnauba wax to protect and shine. I used the Rub and Buff antique gold on the stamping to give it the same look as before and then rubbed down the bowl with a light coat of olive oil before calling it a night. The olive oil soaked in and blended the sanded area of the shank and the topped rim with the rest of the pipe. I sanded the rim, shank and bowl with micromesh sanding pads to smooth out any scratches left behind by the sanding sponges. I usually do this while the oil is on the surface of the briar as the oil gives bite to the micromesh sanding pads. The next four photos show the pipe as it looked when I quit for the evening.

I buffed the stem with White Diamond and then gave it several coats of carnauba wax to protect and shine. I used the Rub and Buff antique gold on the stamping to give it the same look as before and then rubbed down the bowl with a light coat of olive oil before calling it a night. The olive oil soaked in and blended the sanded area of the shank and the topped rim with the rest of the pipe. I sanded the rim, shank and bowl with micromesh sanding pads to smooth out any scratches left behind by the sanding sponges. I usually do this while the oil is on the surface of the briar as the oil gives bite to the micromesh sanding pads. The next four photos show the pipe as it looked when I quit for the evening.

In the morning I buffed the pipe with a Blue Diamond wheel and then gave it multiple coats of carnauba wax to bring a shine to the pipe. The finished pipe is shown below. I am still undecided if I will leave the slight bend in the stem or not. We shall see.

In the morning I buffed the pipe with a Blue Diamond wheel and then gave it multiple coats of carnauba wax to bring a shine to the pipe. The finished pipe is shown below. I am still undecided if I will leave the slight bend in the stem or not. We shall see.

The next two photos – top and bottom view turned out more read in the photos than they are in real life. The colour of the bowl is more properly shown in the photos above and the close-up photos following them.

The next two photos – top and bottom view turned out more read in the photos than they are in real life. The colour of the bowl is more properly shown in the photos above and the close-up photos following them.