Blog by Anthony Cook

I recently completed work on another pipe in the batch that was sent to me by an online friend. This time, it was a Medico Jet Stream. These were produced by Medico from sometime around 1965 until 1971. There were a couple of shapes in the line and each was quite a departure from the classic forms. This one is by far my favorite. I think it has a nice, streamlined flow to it. The pipe is right at six inches long with a small bowl that is barely more than inch tall. Mechanically it was sound but it was obvious that it had let itself go cosmetically in its 44 years (at minimum) of existence.

There were no deep dents or scratches in the stummel, but it did have some light charring and a few nicks around the rim. It was coated with a thick layer of deeply tinted lacquer that had been worn to bare wood in spots. It looked like there might be some interesting grain under there, but the fills… Oh, Jeeze! The fills!!! It was so riddled with them that it looked like it had the pox. The nylon stem was in predictable shape for a pipe of this age with jagged chatter and tooth dents on both sides. You can see the condition of the pipe when it arrived in the following photos.

I began by cleaning the internals of the pipe. The cake in the bowl was light and reamed out easily enough. I think removing the old cake really helps to eliminate any ghosting issues that a pipe may have. So, I took it down to bare wood. I made a surprising and disappointing discovery at that point. The fills did not stop on the outside of the bowl. There were at least two fills in the inside of the chamber. Oh, Medico, say it ain’t so!

I began by cleaning the internals of the pipe. The cake in the bowl was light and reamed out easily enough. I think removing the old cake really helps to eliminate any ghosting issues that a pipe may have. So, I took it down to bare wood. I made a surprising and disappointing discovery at that point. The fills did not stop on the outside of the bowl. There were at least two fills in the inside of the chamber. Oh, Medico, say it ain’t so!

I took the opportunity to sand out a few of the nicks on the inner rim while I was working in the area, and then moved on to the rest of the pipe. There turned out to be quite a bit of residue inside the shank and stem. I took care of that by running a variety of alcohol soaked pipe cleaners, cotton swabs, and shank brushes through until they came out clean. When I was satisfied that the internals were clean, I gave the stummel an acetone wipe-down to get rid of the spotty lacquer coat, and then dropped it into an alcohol bath to remove the remaining of the finish. Usually, there’s a satisfying Ker-Plink! when I do this and the stummel goes right to the bottom. Not this time. This one actually floated belly-up like a dead fish. I had to put tweezers in to hold it down to make sure the entire thing was submerged. I’m guessing that it was the fault of the fills, but it’s a good thing that we weren’t in Salem, Massachusetts. If we were, I would have had to get out the pitchfork and call the Witch Finder General.

When I was satisfied that the internals were clean, I gave the stummel an acetone wipe-down to get rid of the spotty lacquer coat, and then dropped it into an alcohol bath to remove the remaining of the finish. Usually, there’s a satisfying Ker-Plink! when I do this and the stummel goes right to the bottom. Not this time. This one actually floated belly-up like a dead fish. I had to put tweezers in to hold it down to make sure the entire thing was submerged. I’m guessing that it was the fault of the fills, but it’s a good thing that we weren’t in Salem, Massachusetts. If we were, I would have had to get out the pitchfork and call the Witch Finder General. While the stummel enjoyed a pleasant soak, I went to work on the nylon stem. The first step was to clean the surface with citrus cleaner and cubes cut from a Magic Eraser. There really wasn’t very much filth to remove and it cleaned up quickly. The photo below shows the stem after the surface cleaning.

While the stummel enjoyed a pleasant soak, I went to work on the nylon stem. The first step was to clean the surface with citrus cleaner and cubes cut from a Magic Eraser. There really wasn’t very much filth to remove and it cleaned up quickly. The photo below shows the stem after the surface cleaning. Next, I set out to remove the dents and chatter around the button. I began by roughing up the area around the dent with the point of needle file to give the patch a better surface to cling to, and then filled the dents with a drop of black CA glue (seen in the first picture below). When the glue had dried, I sanded it back with 220-grit paper and refilled the area with glue. I did this on both sides of the stem until the dents were filled and level with the rest of the stem surface. I then sanded out the high spots of the chatter with 320-grit paper (seen in the second picture below) and followed that with 400-grit, then 600-grit to give the area a completely smooth surface.

Next, I set out to remove the dents and chatter around the button. I began by roughing up the area around the dent with the point of needle file to give the patch a better surface to cling to, and then filled the dents with a drop of black CA glue (seen in the first picture below). When the glue had dried, I sanded it back with 220-grit paper and refilled the area with glue. I did this on both sides of the stem until the dents were filled and level with the rest of the stem surface. I then sanded out the high spots of the chatter with 320-grit paper (seen in the second picture below) and followed that with 400-grit, then 600-grit to give the area a completely smooth surface.

With the dents filled and the chatter removed, I lightly sanded the entire stem with 1200-grit paper to even out the surface. Then, I used the full complement of micromesh sanding pads 1500-12,000 to polish the stem. You can see the results of the finished stem in the photo below.

With the dents filled and the chatter removed, I lightly sanded the entire stem with 1200-grit paper to even out the surface. Then, I used the full complement of micromesh sanding pads 1500-12,000 to polish the stem. You can see the results of the finished stem in the photo below. The stem work was all wrapped up. So, I pulled the stummel out of the alcohol bath to see what I had to work with. The bath had done an excellent job of removing the old finish and exposing the briar wood. Unfortunately, it has also done an excellent job of exposing all of the fills. I counted fifteen of them in all and that’s not counting the ones in the chamber.

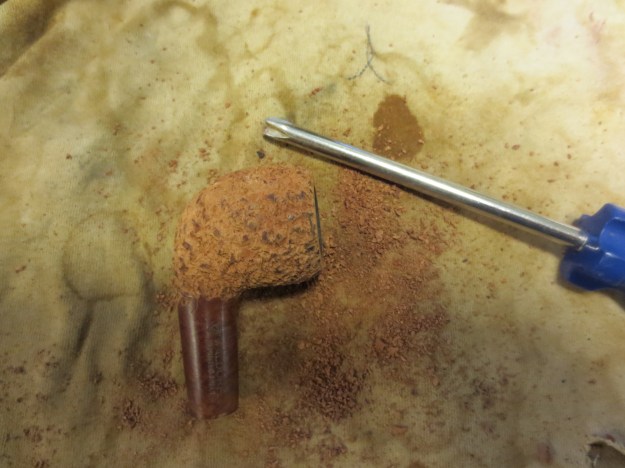

The stem work was all wrapped up. So, I pulled the stummel out of the alcohol bath to see what I had to work with. The bath had done an excellent job of removing the old finish and exposing the briar wood. Unfortunately, it has also done an excellent job of exposing all of the fills. I counted fifteen of them in all and that’s not counting the ones in the chamber. After using a pick set to remove all of the pink fill material on the outside stummel surface, it looked like a block of Swiss cheese. At that point, I had to admit that I didn’t see any way that I could fill all of those pits and hope to have them blend them into the final pipe without the benefit of the tinted lacquer to cover them.

After using a pick set to remove all of the pink fill material on the outside stummel surface, it looked like a block of Swiss cheese. At that point, I had to admit that I didn’t see any way that I could fill all of those pits and hope to have them blend them into the final pipe without the benefit of the tinted lacquer to cover them. Rustication seemed like my best way forward, but I really didn’t want to go that way. I felt that it would really break up the great flow of the shape and stop the movement. I know when I’m whipped, though, and with all of the pits it appeared to be partially rusticated already.

Rustication seemed like my best way forward, but I really didn’t want to go that way. I felt that it would really break up the great flow of the shape and stop the movement. I know when I’m whipped, though, and with all of the pits it appeared to be partially rusticated already.

I decided to leave the rim, the shank end, and the area around the stamping smooth. That meant that I would have at least one pit on the rim to fill. I packed it with briar dust that I have gathered from work on other pipes, and then dripped a small dab of clear CA glue into the dust. When the glue was dry, I sanded it level with the surface. With that out of the way, I prepared to rusticate the surface.

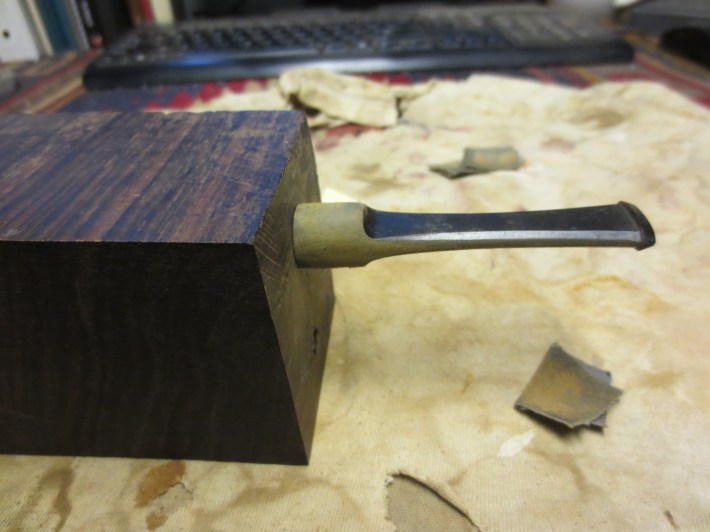

I have a variety of tools that I use to carve into the briar. Some of them are handmade and others are off-the-shelf tools, but my favorite is an old Craftsman T-handle tap wrench. It has a chuck on the end that will accommodate any ¼”–½” bit. It makes it very easy to switch out any of the several bits of various sizes and shapes that I have modified for carving different textures. The chuck provides a tight grip without any of the “wobble” that I’ve encountered when using a bit in a standard driver.

For this project, I began by using modified Phillips bits similar to what Steve has previously detailed here. First, I taped off the end of the shank with painter’s tape to make sure that I didn’t carve into that area. Then, I used a #2 bit to carve around the stummel, twisting and turning as I went. I wanted a deep, craggy texture to give some good contrast with the smooth areas. I switched to a smaller #1 bit for a little more control while I edged up to the smooth areas. The photo below shows the tool and the stummel after I had just started carving. After carving with the bits, I used a wire brush to remove any loose material in the texture. Then, I had the idea that I might be able to restore some of the movement in the shape by carving a few deep “waves” into the rustication. I used a Sharpie pen to sketch some curved lines onto the texture to test out my idea and to give me something to follow should I choose to go that way. I liked it well enough and decided to go ahead. I never pass up an opportunity to break out my trusty Dremel (it really is an addictive tool). So, I fitted it with a #107 engraving bit and etched in the lines that you see in the following photo.

After carving with the bits, I used a wire brush to remove any loose material in the texture. Then, I had the idea that I might be able to restore some of the movement in the shape by carving a few deep “waves” into the rustication. I used a Sharpie pen to sketch some curved lines onto the texture to test out my idea and to give me something to follow should I choose to go that way. I liked it well enough and decided to go ahead. I never pass up an opportunity to break out my trusty Dremel (it really is an addictive tool). So, I fitted it with a #107 engraving bit and etched in the lines that you see in the following photo. I then used a smaller #108 engraving bit to etch a few divergent “cracks” off of the curved lines. This was followed up with some more work with hand carving tools to give it a more natural, less machined, look. I went over it again with the wire brush, and then used 400-grit paper to slightly smooth the peaks for a better tactile feel. You can see the final rustication texture in the photo below (the dark spots are the remains of my Sharpie lines).

I then used a smaller #108 engraving bit to etch a few divergent “cracks” off of the curved lines. This was followed up with some more work with hand carving tools to give it a more natural, less machined, look. I went over it again with the wire brush, and then used 400-grit paper to slightly smooth the peaks for a better tactile feel. You can see the final rustication texture in the photo below (the dark spots are the remains of my Sharpie lines). Then it was time to stain. I used isopropyl alcohol to thin some black Fiebing’s leather dye 3 to 1, applied it to rusticated area with a cotton swab, and flamed it. Then, I heated the wood with a heat gun until it was very warm to the touch and used a 20/0 liner brush to paint the dye across the grain in the smooth areas.

Then it was time to stain. I used isopropyl alcohol to thin some black Fiebing’s leather dye 3 to 1, applied it to rusticated area with a cotton swab, and flamed it. Then, I heated the wood with a heat gun until it was very warm to the touch and used a 20/0 liner brush to paint the dye across the grain in the smooth areas. After allowing the stain to set, I lightly sanded the entire stummel with 600-grit paper. This included sanding the surface of the rusticated areas to give it some highlights to accent the darker crevices. I then gave the entire stummel two coats of dark brown stain thinned with alcohol, and flamed it between each one.

After allowing the stain to set, I lightly sanded the entire stummel with 600-grit paper. This included sanding the surface of the rusticated areas to give it some highlights to accent the darker crevices. I then gave the entire stummel two coats of dark brown stain thinned with alcohol, and flamed it between each one. The stummel was hand-buffed with a cotton cloth. The smooth areas were then lightly sanded with 1200-grit. I also lightly and strategically sanded a few of peaks in the rustication around the smooth areas to allow one texture to fade into the other a bit. I then used micromesh pads 1500-2400 in the same manner.

The stummel was hand-buffed with a cotton cloth. The smooth areas were then lightly sanded with 1200-grit. I also lightly and strategically sanded a few of peaks in the rustication around the smooth areas to allow one texture to fade into the other a bit. I then used micromesh pads 1500-2400 in the same manner.

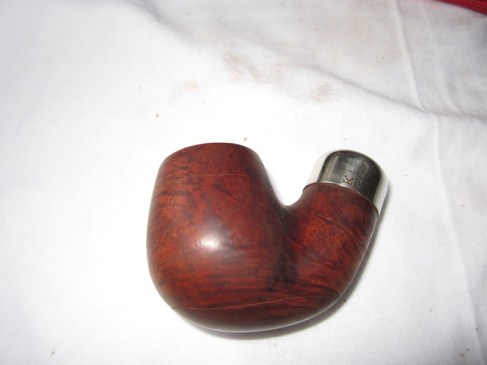

Another couple of stain coats were then applied to the stummel using the same mix and technique that I had used earlier. This time, it was an ox blood stain to add some brightness. Then, I continued with the remaining grits of the micromesh pads. When done with the pads, I gave the stummel a couple of coats of Halcyon wax to wrap up the work.

I think the rustication worked out fairly well and it has a great feel in the hand. You can judge for yourself from the photos of the completed pipe below. I’ll always wonder what could have been if I had left it smooth, though. I guess I’m on the hunt for another Jet Stream so that I can find out!