Blog by Steve Laug

It seems like lately I have had a few of these pipes with broken stems. I have gotten several emails through the blog asking for more information about how I go about cutting back a stem and reshaping it. Since I just finished working on the Yves St. Claude pipe where I did cut back the stem and reshape the button I thought I would use it as an example of the process. I figured that this provided the perfect opportunity to spell out more of the details that I hinted at in the full blog on the restoration of the pipe. The pictures below will show the progress from broken stem to a short saddle stem. It is only one of the methods for addressing a broken stem. Stem splicing and stem replacement are also possible solution. Soon I hope to have another blog on stem splicing but until then have a look at the piece by Jacek Rochacki where he demonstrates his method. https://rebornpipes.com/2014/02/28/some-remarks-on-dealing-with-damaged-stems-of-smoking-pipes-by-jacek-a-rochacki/

1. Before I cut off anything on a stem I spend quite a bit of time examining the broken stem. For me that means checking out the thickness of the stem material above and below the airway in the stem. There needs to be enough thickness that I can shape a button on the cut off portion. I check out the stability of the vulcanite to see if it crumbling or if the break is clean. Sometimes you need to cut quite a ways back into the stem to get either the correct thickness or stability to reform a button. I always try to imagine what the pipe will look like with a shorter stem. To help me see it I have devised a simple method. I clasp it between my thumb and finger making a straight line across the stem. Using my finger and thumb I can slide the stem as far as I want between the fingers and get a good picture of what the pipe will look like with a shorter stem. If all of these steps are passed then I get ready to cut off the broken portion.

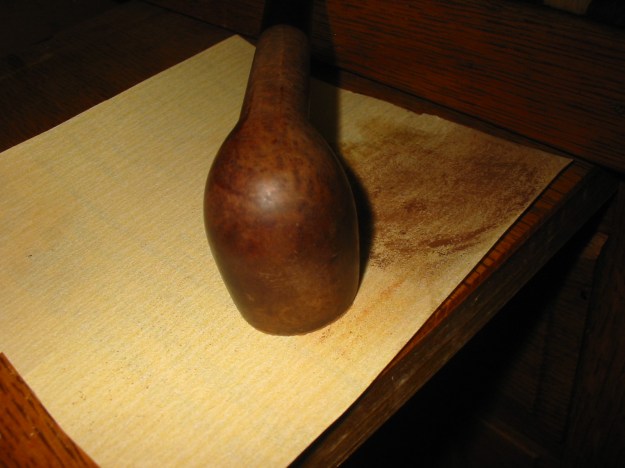

This stem passed all the tests. The break not straight across the stem but actually was slightly diagonal. It was a very clean break with no crumbling material. The airway appears to be close to the surface on the top side of the stem but because of the angle of the break there was sufficient material there for me to cut and shape a button. I was ready to cut of this stem.

2. I marked the stem with a pencil to delineate how far I planned on cutting the stem. I use a Dremel with a sanding drum to cut off the broken portion of the stem to the point of my line. Others use coping saws or hacksaws to remove the material. Choose whatever tool you are comfortable with to do the work. For me I hold the Dremel in my right hand and the stem in my left. I keep the stem stationary while cutting but frequently rotate it in my hand to keep the edges straight. I am always conservative in the first cut only taking off what looks to be necessary. I want a solid surface to work on with the button. Once I have the cut finished I use the drum to slightly round the corners of the line. In the end I wanted to have a slight crown on the finished button so I plan for that at this point. In the two photos below you can see the slightly bow in the cut off. The cut off edge is vertical to the surface of the stem forming a 90 degree angle.

2. I marked the stem with a pencil to delineate how far I planned on cutting the stem. I use a Dremel with a sanding drum to cut off the broken portion of the stem to the point of my line. Others use coping saws or hacksaws to remove the material. Choose whatever tool you are comfortable with to do the work. For me I hold the Dremel in my right hand and the stem in my left. I keep the stem stationary while cutting but frequently rotate it in my hand to keep the edges straight. I am always conservative in the first cut only taking off what looks to be necessary. I want a solid surface to work on with the button. Once I have the cut finished I use the drum to slightly round the corners of the line. In the end I wanted to have a slight crown on the finished button so I plan for that at this point. In the two photos below you can see the slightly bow in the cut off. The cut off edge is vertical to the surface of the stem forming a 90 degree angle.

3. When the cut off is finished I take time to look at the profile of the stem. In this case the stem was quite thick. I was going to need to shave off the surface and thin the stem down but I would not do that until I had cut the button and roughed in the shape. Looking at it I could also see that I would need to flatten the stem near the new button as it had a definite rounding that would make it uncomfortable in the mouth.

3. When the cut off is finished I take time to look at the profile of the stem. In this case the stem was quite thick. I was going to need to shave off the surface and thin the stem down but I would not do that until I had cut the button and roughed in the shape. Looking at it I could also see that I would need to flatten the stem near the new button as it had a definite rounding that would make it uncomfortable in the mouth.

4. The first tools that I use are a knife shaped needle file that has a thin edge like a blade and squared edge for the initial cuts and a folded piece of 220 grit sandpaper to clean up the newly cut edge.

4. The first tools that I use are a knife shaped needle file that has a thin edge like a blade and squared edge for the initial cuts and a folded piece of 220 grit sandpaper to clean up the newly cut edge. 5. I cut the edge with the straight edge of the file. I eyeball the line to make sure it aligns on both sides of the stem. This is a bit tricky at first but I rotate the stem to and angle where I can see both sides at once and begin the second cut. At this point in the process I am not finishing the cut but only drawing the line with the file. With the line cut and the button edge defined there is a lot of finishing work that needs to be done but you can get a clear picture of what the button will look like.

5. I cut the edge with the straight edge of the file. I eyeball the line to make sure it aligns on both sides of the stem. This is a bit tricky at first but I rotate the stem to and angle where I can see both sides at once and begin the second cut. At this point in the process I am not finishing the cut but only drawing the line with the file. With the line cut and the button edge defined there is a lot of finishing work that needs to be done but you can get a clear picture of what the button will look like.

6. I use the knife edge of the file to shave the surface of the stem on the top and bottom sides. Be careful not to gouge the surface but smoothly shave it. I hold the blade at slight angle against the surface of the stem and carve toward the button. I have the stem on the table and work the blade away from myself sometimes and other times I have it in hand with the new button against the heel of my palm and work the blade toward the button. I work the blade until I have defined the line of the button and flattened the crown on the surface of the stem. Remember this is all initial carving. It will be cleaned up and smoothed out with the sandpaper and other files.

7. When I have the material in front of the button cut away and thinned down I sand it with the folded 220 grit sandpaper to get an idea of how it looks and of how much more I will need to remove from the crown on both sides of the stem. In the case of this stem I have enough material removed. I still need to shape the button and clean up the edges of the sharp edge. The top and bottom surface of the button still need to be shaped and sanded but the overall look is good to go.

7. When I have the material in front of the button cut away and thinned down I sand it with the folded 220 grit sandpaper to get an idea of how it looks and of how much more I will need to remove from the crown on both sides of the stem. In the case of this stem I have enough material removed. I still need to shape the button and clean up the edges of the sharp edge. The top and bottom surface of the button still need to be shaped and sanded but the overall look is good to go.

8. With the rough shape finished I cut the slot in the end of the button and flare the airway. The first photo below shows the way the airway looked once I cut of the stem. You can see that there is plenty of material above and below the airway. I started the process by sanding the face of the button on my topping board and sandpaper. It is important to make sure that stem is absolutely vertical and does not tilt either way when doing this. You want to make a smooth face to work on the slot.

8. With the rough shape finished I cut the slot in the end of the button and flare the airway. The first photo below shows the way the airway looked once I cut of the stem. You can see that there is plenty of material above and below the airway. I started the process by sanding the face of the button on my topping board and sandpaper. It is important to make sure that stem is absolutely vertical and does not tilt either way when doing this. You want to make a smooth face to work on the slot. 9. I use several different needle files to open the slot. The first file I use is a flattened oval file shown in the photo below. I work it against the right and left edges of the airway to open the slot. I don’t worry about the finished look at this point but am concerned to rough it in with the file. The flattened oval does the initial shaping work. I like a slot that is oval and tapers to a point on each side. I also work the file into the airway to taper the internals into a Y shaped funnel ending at the airway.

9. I use several different needle files to open the slot. The first file I use is a flattened oval file shown in the photo below. I work it against the right and left edges of the airway to open the slot. I don’t worry about the finished look at this point but am concerned to rough it in with the file. The flattened oval does the initial shaping work. I like a slot that is oval and tapers to a point on each side. I also work the file into the airway to taper the internals into a Y shaped funnel ending at the airway. 10. I work the top and bottom edges with the second file – an oval blade that is not flattened and almost round. I use it to work the internals into more of a smooth Y and then open the top and bottom of the slot. I follow this with a round needle file that has a thin point to clean up the opening and shape it. The photo below shows the slot after I have used all three files.

10. I work the top and bottom edges with the second file – an oval blade that is not flattened and almost round. I use it to work the internals into more of a smooth Y and then open the top and bottom of the slot. I follow this with a round needle file that has a thin point to clean up the opening and shape it. The photo below shows the slot after I have used all three files. 11. I fold a piece of sandpaper into a rectangle that I can fit into the slot. I work it in the slot to sand the internals and remove the file marks. I sand the face of the button to remove file marks and also sand the slot to refine the shape of oval.

11. I fold a piece of sandpaper into a rectangle that I can fit into the slot. I work it in the slot to sand the internals and remove the file marks. I sand the face of the button to remove file marks and also sand the slot to refine the shape of oval. 12. The next photo shows the slot after I have worked it with the sandpaper. The internals are clean and smooth. I then use a pipe cleaner and isopropyl alcohol to remove any dust from the inside of the airway. The face of the stem still shows some light scratching that will be taken care of with wet sanding using micromesh sanding pads. However, you can see the new shape of the slot and how it sits on the button. That portion of the reshaping of the new button is finished and all that remains is to sand and polish the stem with the micromesh and the buffer.

12. The next photo shows the slot after I have worked it with the sandpaper. The internals are clean and smooth. I then use a pipe cleaner and isopropyl alcohol to remove any dust from the inside of the airway. The face of the stem still shows some light scratching that will be taken care of with wet sanding using micromesh sanding pads. However, you can see the new shape of the slot and how it sits on the button. That portion of the reshaping of the new button is finished and all that remains is to sand and polish the stem with the micromesh and the buffer. 13. I sanded the stem – all surfaces including the button face with a medium and a fine grit sanding sponge to remove the scratches left behind by the 220 grit sandpaper. I worked on giving the surface of the button a slight bevel downward toward the slot. I personally like a gentle slope so I don’t overdo it with the sanding.

13. I sanded the stem – all surfaces including the button face with a medium and a fine grit sanding sponge to remove the scratches left behind by the 220 grit sandpaper. I worked on giving the surface of the button a slight bevel downward toward the slot. I personally like a gentle slope so I don’t overdo it with the sanding.

14. With the scratches removed the stem is ready for polishing. I used micromesh sanding pads to do this work. Others use high grit wet dry sandpapers or micromesh papers. I like the way the pads fit in my fingers and how I can push the edge up against the slot to work that angle. I wet sand with 1500-2400 grit pads – wetting the surface of the stem and then sanding with the pads. I wipe it off regularly to remove the grime and check on the smoothness of the surface. I sand with each of the three grits until the particular grit no longer takes off any of the vulcanite. Once I finish with the three pads I rub the stem down with Obsidian Oil as I find it highlights the remaining scratches and also helps the micromesh to bite into the surface of the stem. I have used olive oil to do the same thing, applying it sparingly with a fold piece of cloth or paper towel. At times I have applied the oil between each of these three grits – essentially replacing the water with the oil. It works very well.

14. With the scratches removed the stem is ready for polishing. I used micromesh sanding pads to do this work. Others use high grit wet dry sandpapers or micromesh papers. I like the way the pads fit in my fingers and how I can push the edge up against the slot to work that angle. I wet sand with 1500-2400 grit pads – wetting the surface of the stem and then sanding with the pads. I wipe it off regularly to remove the grime and check on the smoothness of the surface. I sand with each of the three grits until the particular grit no longer takes off any of the vulcanite. Once I finish with the three pads I rub the stem down with Obsidian Oil as I find it highlights the remaining scratches and also helps the micromesh to bite into the surface of the stem. I have used olive oil to do the same thing, applying it sparingly with a fold piece of cloth or paper towel. At times I have applied the oil between each of these three grits – essentially replacing the water with the oil. It works very well. 15. I dry sand (no oil or water) with the remaining grits of micromesh. I sand with 3200-4000 grit pads and then rub the stem down with oil again for the same reasons as above. I then either go back to the 1500-2400 grit pads to rework areas of concern or move on to sanding with the 6000-12,000 grit pads.

15. I dry sand (no oil or water) with the remaining grits of micromesh. I sand with 3200-4000 grit pads and then rub the stem down with oil again for the same reasons as above. I then either go back to the 1500-2400 grit pads to rework areas of concern or move on to sanding with the 6000-12,000 grit pads.

16. I buff the stem with White Diamond at this point in my process. If you do not have a buffer you can buff with a plastic polish on a cotton pad or cloth. The idea is to remove any of the remaining scratches (micro scratches really at this point) and give the vulcanite a high sheen. When I finish buffing I give the stem multiple coats of carnauba wax. When I did not have my buffer I used Kiwi neutral shoe wax which has carnauba in it and hand buffed the stem with a shoe brush. Sometimes I revert to using the shoe brush even now. Especially when buffing areas around stamping and logos.

16. I buff the stem with White Diamond at this point in my process. If you do not have a buffer you can buff with a plastic polish on a cotton pad or cloth. The idea is to remove any of the remaining scratches (micro scratches really at this point) and give the vulcanite a high sheen. When I finish buffing I give the stem multiple coats of carnauba wax. When I did not have my buffer I used Kiwi neutral shoe wax which has carnauba in it and hand buffed the stem with a shoe brush. Sometimes I revert to using the shoe brush even now. Especially when buffing areas around stamping and logos.

17. The finished stem is shown below. The button looks like it has always been there. I like giving it a look that fits the age of the pipe. I don’t want it looking like a brand new button that has been tacked onto an old pipe. Rather I want it to look as if it has been there for the life of the pipe and has seen some smoothing from use. You can be the judge if I have achieved that but at least that is the aim. You can also decide how you want the buttons that you shape to look. Don’t be afraid to experiment and add your own steps or modify these so that they work for you. The end result is really all we are interested in anyway and the methods for getting there are many.