by Steve Laug

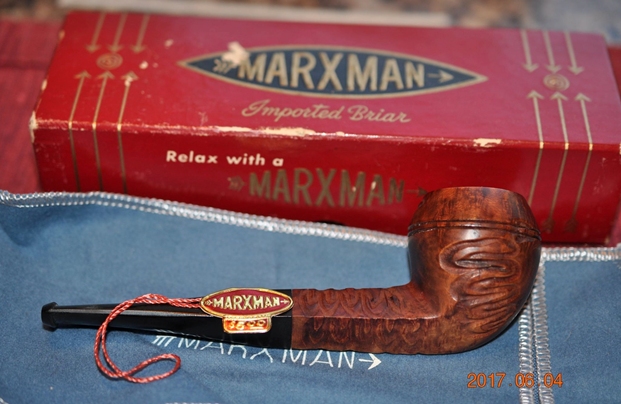

The next pipe on the table was a bowl sans stem that I have had in my box of bowls to be restemmed. It is stamped on the left side of the shank and reads Marxman with an arrow running through it [over] Imported Briar. The rounded Apple shape had some great grain around the sides of the bowl and shank. From my previous work on one of these I knew that I was dealing with an American made product. The pipe had been reamed and cleaned by my brother Jeff many years ago. The rim and the inner edge were clean and looked to be in good condition. The finish had been scrubbed and it was very clean. I took some photos of the bowl before I worked on it and fit it with a new stem.

I found a thick vulcanite taper stem in my can of stems that would work with some adjustments. The tenon would need to be reduced in diameter and the diameter of the shank end would also need to be reduced. The size and shape of the stem were perfect to start with.

I found a thick vulcanite taper stem in my can of stems that would work with some adjustments. The tenon would need to be reduced in diameter and the diameter of the shank end would also need to be reduced. The size and shape of the stem were perfect to start with.  I took photos of the stamping on the left side of the shank. It is clear and readable as noted above. I took a photo of the parts of the pipe. It is going to be a beautiful pipe once it is completed.

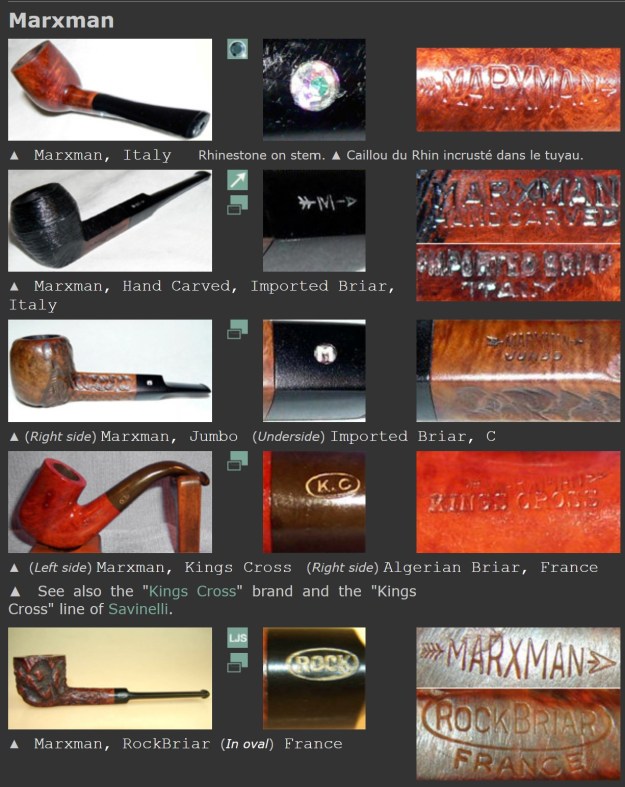

I took photos of the stamping on the left side of the shank. It is clear and readable as noted above. I took a photo of the parts of the pipe. It is going to be a beautiful pipe once it is completed. I turned to Pipephil’s site to look at the data that was available on Marxman pipes and see if there were any pipes like the bowl I had (http://www.pipephil.eu/logos/en/logo-m2.html). There was nothing in the photos there but the stampingi and data available was helpful. I have included the sidebar information below the screen capture.

I turned to Pipephil’s site to look at the data that was available on Marxman pipes and see if there were any pipes like the bowl I had (http://www.pipephil.eu/logos/en/logo-m2.html). There was nothing in the photos there but the stampingi and data available was helpful. I have included the sidebar information below the screen capture. Brand created in 1934 and merged with Mastercraft in 1953.

Brand created in 1934 and merged with Mastercraft in 1953.

From that information I knew that bowl was crafted between 1934 when the Marxman Brand created and when it merged with Mastercraft in 1953. It is a large margin but it gives me a 19-year window as to when the bowl was made.

From there I turned to Pipedia’s listing on Marxman pipes (https://pipedia.org/wiki/Marxman). The brief article quotes from Pipes, Artisans and Trademarks, by José Manuel Lopes. I have included the information on there below.

Marxman (Marxman Pipe Company) was created by Robert (Bob) L. Marx in 1934, when he was 29, and after he had worked for the William Demuth Company. His pipes were not outstanding because of the quality of their wood (probably Algerian), but Bob started making unique sculpted pieces, which brought the brand fame in the World of Hollywood cinema. Actors like Zachery Scott, Dennis Morgan, Jack Carson, Alan Hale, Joel McRae, and Ronald Reagan were some of the faces that appeared on the bowls.

Bob knew how to innovate and took full advantage of marketing and press advertising in order to sell the brand–one of his slogans being “Relax with a Marxman”.

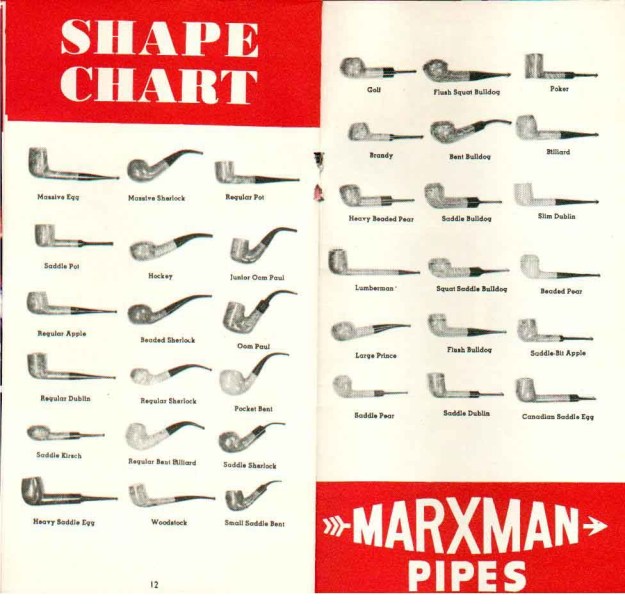

The article also included a shape chart that was helpful. It looked to me that the pipe was a Marxman Massive Sherlock. It is the top pipe in the second column in the photo below. I started my work on the stem by reducing the diameter of the tenon to fit in the shank. I used a Dremel and sanding drum to begin the process and cleaned it up with a flat file. Once I finished shaping it I fit the stem to the shank. The fit was snug. The diameter of the stem itself was larger than the diameter of the shank. That is visible in the photos below.

I started my work on the stem by reducing the diameter of the tenon to fit in the shank. I used a Dremel and sanding drum to begin the process and cleaned it up with a flat file. Once I finished shaping it I fit the stem to the shank. The fit was snug. The diameter of the stem itself was larger than the diameter of the shank. That is visible in the photos below.

I used the Dremel and sanding drum to reduce the diameter of the stem as much as I safely could do and then cleaned it up with 220 grit sandpaper to smooth out and shape the stem.

I used the Dremel and sanding drum to reduce the diameter of the stem as much as I safely could do and then cleaned it up with 220 grit sandpaper to smooth out and shape the stem.  I used a flat file to reduce the diameter of the shank. It worked well to remove the excess vulcanite to match diameter of the shank. It was getting there.

I used a flat file to reduce the diameter of the shank. It worked well to remove the excess vulcanite to match diameter of the shank. It was getting there.

I decided to fit the shank with a thin polished nickel band to set off the briar and the new stem. I reduced the depth of the band by 2/3rds with a Dremel, sanding drum and topping board. When I had it thin enough to not cover too much of the stamp on the shank it was ready to use.

I decided to fit the shank with a thin polished nickel band to set off the briar and the new stem. I reduced the depth of the band by 2/3rds with a Dremel, sanding drum and topping board. When I had it thin enough to not cover too much of the stamp on the shank it was ready to use. I pressed it onto the shank and took photos of the adjusted look of the pipe. I really like the look of the band.

I pressed it onto the shank and took photos of the adjusted look of the pipe. I really like the look of the band.

I sanded the band and the briar with 320-3500 grit 2×2 inch sanding pads to smooth it out. I wiped the bowl down with a damp cloth after each sanding pad to remove the sanding dust and debris.

I sanded the band and the briar with 320-3500 grit 2×2 inch sanding pads to smooth it out. I wiped the bowl down with a damp cloth after each sanding pad to remove the sanding dust and debris.

I polished the briar and band with 1500-12000 grit micromesh sanding pads. I wiped the bowl down after each sanding pad to remove the sanding debris. The bowl began to take on a rich shine and the finish really glowed.

I polished the briar and band with 1500-12000 grit micromesh sanding pads. I wiped the bowl down after each sanding pad to remove the sanding debris. The bowl began to take on a rich shine and the finish really glowed.

I worked some Before and After Restoration Balm into the finish of the briar with my finger tips. The product works to clean, enrich and restore the briar. The photos show the beauty that pipe really had at this point.

I worked some Before and After Restoration Balm into the finish of the briar with my finger tips. The product works to clean, enrich and restore the briar. The photos show the beauty that pipe really had at this point.

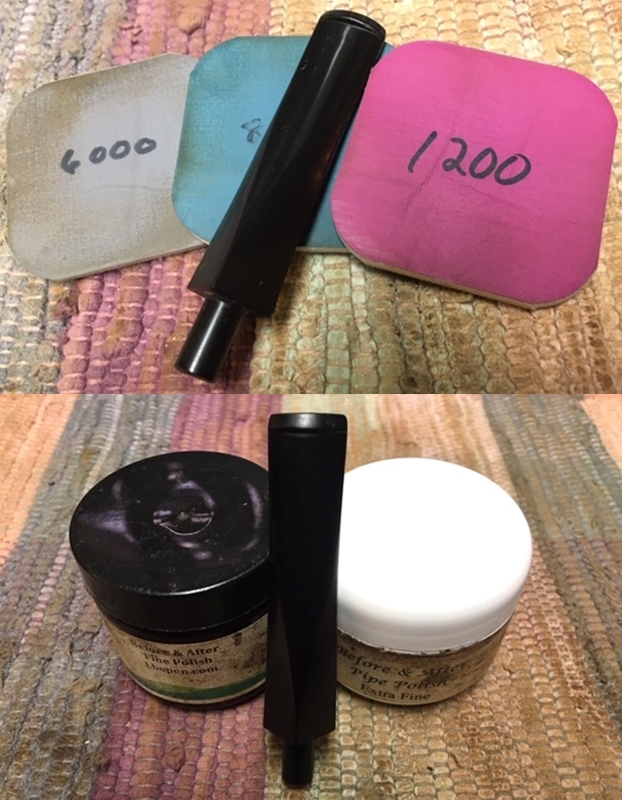

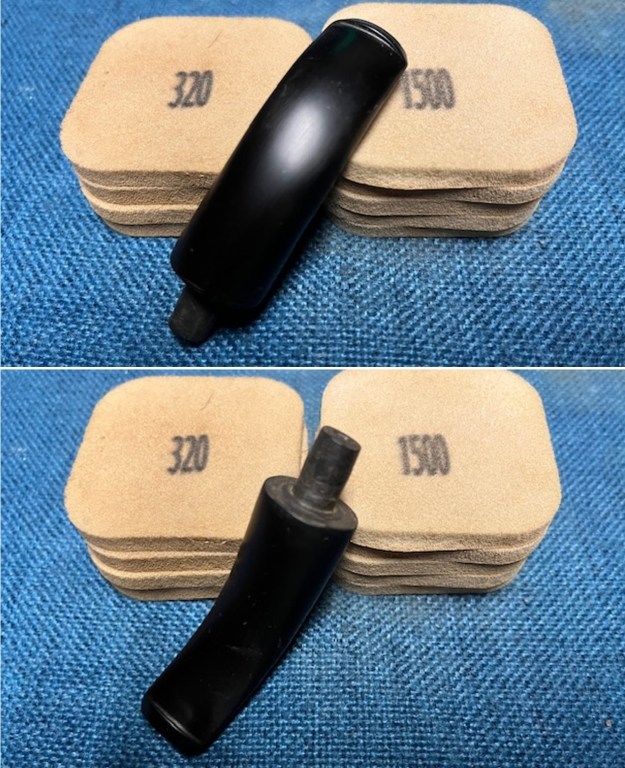

I set the bowl aside and turned my attention to the stem. I sanded out the files marks on the stem surface with a folded piece of 220 grit sandpaper. I moved on to sand the stem with 320-3500 grit 2×2 inch sanding pads. I wiped it down with an Obsidian Oil cloth after each sanding pad to remove the sanding debris. The stem began to look much better.

I set the bowl aside and turned my attention to the stem. I sanded out the files marks on the stem surface with a folded piece of 220 grit sandpaper. I moved on to sand the stem with 320-3500 grit 2×2 inch sanding pads. I wiped it down with an Obsidian Oil cloth after each sanding pad to remove the sanding debris. The stem began to look much better.  I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I wiped it down with Obsidian Oil to protect the stem and slow down the oxidation.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with some Obsidian Oil. I finished polishing it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth. I wiped it down with Obsidian Oil to protect the stem and slow down the oxidation.

I put the restemmed Marxman Imported Briar Apple/Ball back together and buffed it on the buffing wheel with Blue Diamond. It raised a shine on the briar and the stem and gave some depth to the look of the carved grooves. I gave both the bowl and the stem multiple coats of carnauba wax on the wheel and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe turned out to be a unique beauty in its own rugged way. I really like the grain and the shape of this Marxman Apple/Ball. The thin nickel band and the thick bent taper stem go well with the thick shank. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outer diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.29 ounces/64 grams. It is a uniquely beautiful pipe. I am not sure what I am going to do with it yet. It may well be one I keep to enjoy, I will keep you posted. Thanks for walking through the restoration with me.

I put the restemmed Marxman Imported Briar Apple/Ball back together and buffed it on the buffing wheel with Blue Diamond. It raised a shine on the briar and the stem and gave some depth to the look of the carved grooves. I gave both the bowl and the stem multiple coats of carnauba wax on the wheel and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe turned out to be a unique beauty in its own rugged way. I really like the grain and the shape of this Marxman Apple/Ball. The thin nickel band and the thick bent taper stem go well with the thick shank. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outer diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 2.29 ounces/64 grams. It is a uniquely beautiful pipe. I am not sure what I am going to do with it yet. It may well be one I keep to enjoy, I will keep you posted. Thanks for walking through the restoration with me.