by Steve Laug

The next pipe on the table is a beautiful shaped thick shanked Billiard. We recently purchased it from a seller in Wilkes Barr, Pennsylvania, USA on Facebook Auction on Facebook on 09/12/2021. It is a nicely grained large Billiard with mixed grain on the sides and birdseye on the front and the back of the bowl. The inwardly bevelled rim top is in great condition and had mixed grain across the top. It is stamped on the left underside of the shank and reads Jarl Chieftain [over] Made in Denmark. On the right side it is stamped with the shape Oil Hardened. On the underside next to the stem/shank junction it bears the shape number 02. There was a heavy cake in the bowl and some darkening around the top and inner edge and light lava spots on the rim top. The mortise smelled of oils and had a dirty 9mm filter in the tenon. The stem was lightly oxidized, calcified and there were some light tooth marks or chatter on the top and underside ahead of the button. Jeff took photos of the pipe before he started his cleanup work. They tell the story and give a glimpse of the promise that we see in this pipe.

He took a photo of the rim top and bowl to show the current condition. The inner edge and the rim top showed darkening and spots of lava as mentioned above. The photos of the bowl walls show the moderate cake on the walls. The stem photos show the oxidation and light marks on the rim top on both sides.

He took a photo of the rim top and bowl to show the current condition. The inner edge and the rim top showed darkening and spots of lava as mentioned above. The photos of the bowl walls show the moderate cake on the walls. The stem photos show the oxidation and light marks on the rim top on both sides.

Jeff took photos of the sides and heel of the bowl to give a sense of the condition of the bowl and the grain around the bowl. It is a beauty.

Jeff took photos of the sides and heel of the bowl to give a sense of the condition of the bowl and the grain around the bowl. It is a beauty.

He took photos of the shank sides to capture the stamping on the shank sides. They were clear and readable as noted above. Jeff did not capture the shape number on the underside of the shank which was also clear.

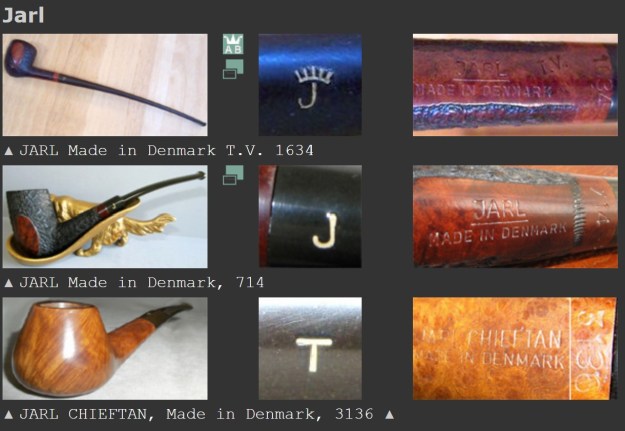

He took photos of the shank sides to capture the stamping on the shank sides. They were clear and readable as noted above. Jeff did not capture the shape number on the underside of the shank which was also clear.  Before I started working on it I did a bit of research on the brand to remind myself of what I knew of the maker. I turned to Pipephil’s site first (http://www.pipephil.eu/logos/en/logo-j1.html#jarl). I did a screen capture of the information on the site. I did a screen capture of the pertinent information and have included it below.

Before I started working on it I did a bit of research on the brand to remind myself of what I knew of the maker. I turned to Pipephil’s site first (http://www.pipephil.eu/logos/en/logo-j1.html#jarl). I did a screen capture of the information on the site. I did a screen capture of the pertinent information and have included it below. I then turned to Pipedia and found that a very short article that confirmed that the pipes were made by Niels Mogens Jorgensen (https://pipedia.org/wiki/Jarl). I have included the article in its entirety below.

I then turned to Pipedia and found that a very short article that confirmed that the pipes were made by Niels Mogens Jorgensen (https://pipedia.org/wiki/Jarl). I have included the article in its entirety below.

In December of 2010 Ellen Jarl wrote that Jarl pipes were made by her grandfather, Niels Mogens Jørgensen in a little factory in the town of Bramdrupdam, just outside Kolding, Denmark. We have no reason to doubt that Niels Mogens Jørgensen is the maker of these pipes.

Now it was time to work on the pipe. Since Jeff always follows the same pattern of work in his cleanup we do not include photos but rather just a simple summary. Jeff reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl. He rinsed it under running water. He dried it off with a soft cloth. He was able to remove the spotty lava build up on the rim top and you could see the marks on the top and edges of the rim. He soaked it in Briarville’s Pipe Stem Deoxidizer and rinsed it with warm water to rinse off the residue. The stem was clean and the oxidation was gone. I took photos of what the pipe looked like when I brought to my worktable.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge looked good. The stem was clean and there were light tooth marks on the top and underside of the stem.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge looked good. The stem was clean and there were light tooth marks on the top and underside of the stem. I took photos of the stamping on the sides of the shank. It is faint in spots but still readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I took photos of the stamping on the sides of the shank. It is faint in spots but still readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I polished the briar with micromesh sanding pads – 1500-12000 grit sanding pads. I wiped the bowl surface down with a damp cloth after each sanding pad to remove the sanding dust. Once I finished the exterior of the briar was clean and the grain really stood out.

I polished the briar with micromesh sanding pads – 1500-12000 grit sanding pads. I wiped the bowl surface down with a damp cloth after each sanding pad to remove the sanding dust. Once I finished the exterior of the briar was clean and the grain really stood out.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

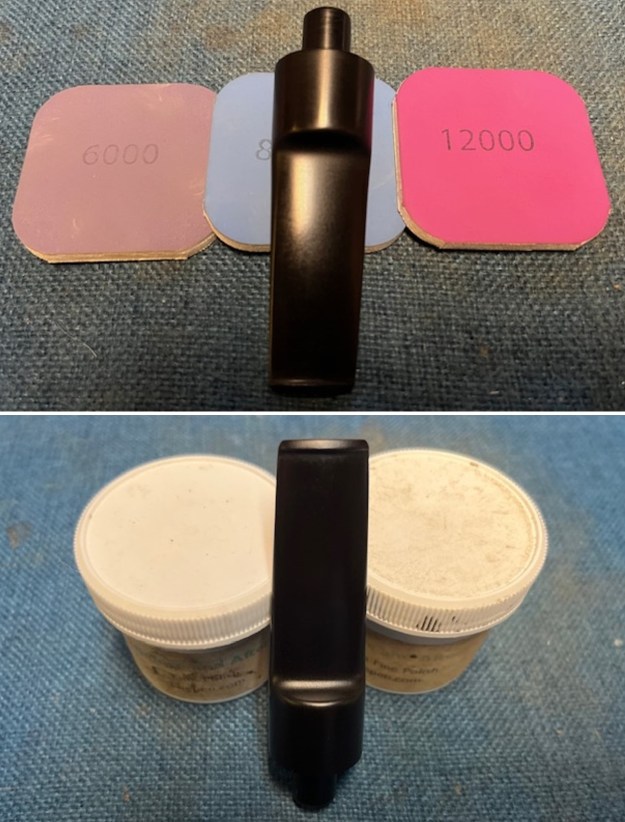

I set the bowl aside and turned to the stem. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of oil and set it aside to dry.

I set the bowl aside and turned to the stem. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of oil and set it aside to dry.

I fit the filter tenon with a clean Dr. Perl Junior 9mm filter. It easily slips into the tenon and the pipe is ready to smoke.

I fit the filter tenon with a clean Dr. Perl Junior 9mm filter. It easily slips into the tenon and the pipe is ready to smoke. I am excited to finish this Jarl Chieftan Made in Denmark Thick Shank Billiard 02 with a 9mm Filter vulcanite saddle stem. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the mix of grain on the sides of the bowl. Added to that the black vulcanite saddle stem was beautiful. This smooth Jarl Chieftan Thick Shank 02 Billiard is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 57 grams /2.05 ounces. It turned out to be a beautiful pipe. I will be putting it on the rebornpipes store in the Danish Pipe Makers section. If you are interested in adding it to your rack let me know by message or by email to slaug@uniserve.com. Thanks for your time reading the blog. I appreciate it.

I am excited to finish this Jarl Chieftan Made in Denmark Thick Shank Billiard 02 with a 9mm Filter vulcanite saddle stem. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I hand buffed the pipe with a clean buffing pad to raise the shine. It is fun to see what the polished bowl looks like with the mix of grain on the sides of the bowl. Added to that the black vulcanite saddle stem was beautiful. This smooth Jarl Chieftan Thick Shank 02 Billiard is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 57 grams /2.05 ounces. It turned out to be a beautiful pipe. I will be putting it on the rebornpipes store in the Danish Pipe Makers section. If you are interested in adding it to your rack let me know by message or by email to slaug@uniserve.com. Thanks for your time reading the blog. I appreciate it.