by Steve Laug

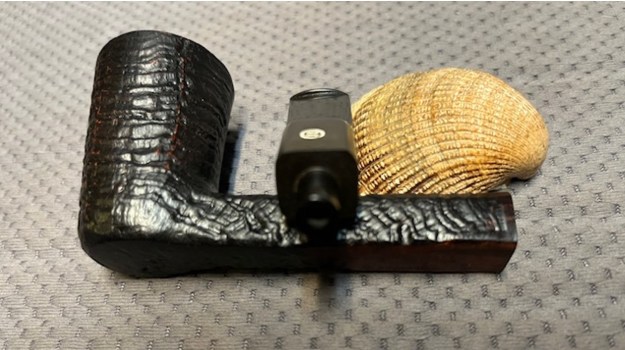

The next pipe on the table is one that we picked up in the lot from a seller in Barrington, Rhode Island, USA on 08/22/2024. The sandblast finish on this pipe and the Upshall stamping are what caught our eye. The pipe has something about it that reminds me of a Charatan pipe. It is stamped on the underside of the shank and reads James Upshall [over] Hand Made [over] In England. To the right of that is the shape stamp 6FH. It has a classic combination of Black and Brown stains on the sandblast finish that is a stark contrast to the vulcanite saddle stem. It is a long Lumberman or long shank Lovat shape square shank pipe with a vulcanite stem. The bowl is a tall Dublin bowl with a smooth rim top and a light cake in the bowl and spots of lava on the rim top. The inner edge and the top look very good other than that. The stem is lightly oxidized. It does not show any tooth marks or chatter on the top and underside ahead of the button. The James Upshall oval JU logo is stamped in white on the top of the stem and looks to be in good condition. Jeff took some photos of the pipe to show the general condition of the pipe before he started his clean up.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. It a light cake on the inside of the bowl and the rim top is spotted with lava. He included photos that show the top and underside of the stem. It is as described above.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. It a light cake on the inside of the bowl and the rim top is spotted with lava. He included photos that show the top and underside of the stem. It is as described above.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos showed some great grain in the sandblast around the bowl and shank. It is a great looking piece of briar.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. The photos showed some great grain in the sandblast around the bowl and shank. It is a great looking piece of briar.

He took a photo of the stamping on the underside of the shank. The stamping was clear and readable as noted above. He also took a photo of the oval JU logo on the topside of the saddle stem.

He took a photo of the stamping on the underside of the shank. The stamping was clear and readable as noted above. He also took a photo of the oval JU logo on the topside of the saddle stem. Before I started my work on the pipe I looked up the Upshall listing on pipephil’s site to see what I could find (http://www.pipephil.eu/logos/en/logo-j1.html#jamesupshall).

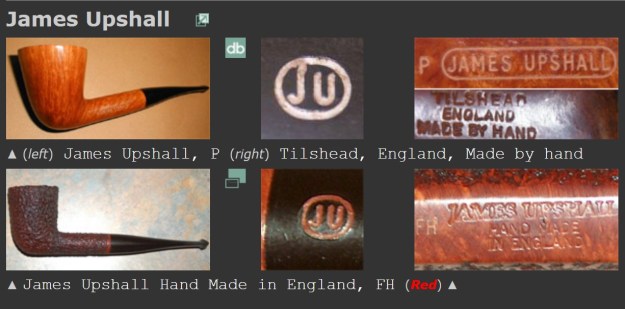

Before I started my work on the pipe I looked up the Upshall listing on pipephil’s site to see what I could find (http://www.pipephil.eu/logos/en/logo-j1.html#jamesupshall). Artisan: Barry Jones learned his skill from the age of 15 at Charatan’s. In 1978 he joined Kenneth Barnes and established the James Upshall brand at Tilshead (Wiltshire). Production (2006): ~ 30 pipes/week

Artisan: Barry Jones learned his skill from the age of 15 at Charatan’s. In 1978 he joined Kenneth Barnes and established the James Upshall brand at Tilshead (Wiltshire). Production (2006): ~ 30 pipes/week

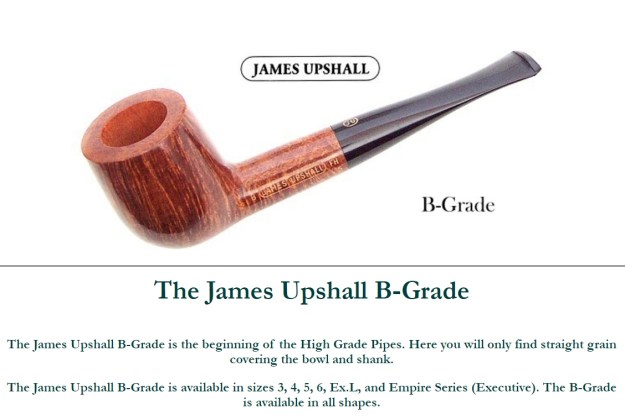

I turned to Pipedia to remind myself of the background on the brand Upshall brand (https://pipedia.org/wiki/James_Upshall). I read through the article and found the section on Grading & Sizing Information really helpful. I have included that below. I have highlighted the pertinent text in red below.

James Upshall pipes are graded by various finishes, i.e. bark, sandblast, black dress and smooth etc. Then by cross grain, flame grain, straight grain and, last but not least, the perfect high grade, which consists of dense straight grain to the bowl and shank. The latter being extremely rare. In addition, the price varies according to group size, i.e. from 3-4-5-6 cm high approximately Extra Large. We also have the Empire Series which are basically the giant size, individually hand crafted pipes which come in all finishes and categories of grain. All our pipes are individually hand carved from the highest quality, naturally dried Greek briar. In order to simplify our grading system, let me divide our pipes into 4 basic categories.

- It begins with the Tilshead pipe, which smokes every bit as good as the James Upshall but has a slight imperfection in the briar. In the same category price wise you will find the James Upshall Bark and Sandblast finish pipes, which fill and smoke as well as the high grades.

- In this category we have the best “root quality” which means that the grain is either cross, flame or straight, which is very much apparent through the transparent differing color finishes. This group will qualify as the “S”- Mahogany Red, “A” – Chestnut Tan and “P” – Walnut. The latter having the straighter grain.

- Here you have only straight grain, high grade pipes, which run from the “B”, “G”, “E”, “X” and “XX”. The latter will be the supreme high grade. Considering the straightness of the grain the latter category is also the rarest. Usually no more than 1% of the production will qualify.

- Lastly, we have the Empire Series. These are basically Limited Edition gigantic individually hand crafted pieces, which again are extremely rare due to the scarcity of large, superior briar blocks.

Armed with that information I turned my attention to the pipe itself. Jeff had cleaned the pipe with his usual penchant for thoroughness that I really appreciate. He reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks very good with good looking grain around the bowl and shank. Jeff soaked the stem in Before & After Deoxidizer to remove the oxidation on the rubber. When the pipe arrived here in Vancouver for the second stop of its restoration tour it looked very good. I took photos before I started my part of the work.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and did not show either tooth marks or chatter.

I took close up photos of the bowl, rim top and stem to show how clean the pipe was. The bowl was clean and the rim top and the inner edge look beautiful. The stem was clean and did not show either tooth marks or chatter. I took a photo of the stamping on the underside of the shank. It is faint in spots but still readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts.

I took a photo of the stamping on the underside of the shank. It is faint in spots but still readable and read as noted above. I also removed the stem from the shank and took photos of the pipe to show the look of the parts. I polished the smooth rim top with 1500-12000 grit micromesh sanding pad – dry sanding it with the pads. I wiped the bowl down with a damp cloth after each pad. It began to take on a deep shine.

I polished the smooth rim top with 1500-12000 grit micromesh sanding pad – dry sanding it with the pads. I wiped the bowl down with a damp cloth after each pad. It began to take on a deep shine.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips and a shoe brush to get into the nooks and crannies. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

The exterior of the bowl look better after sanding. I worked some Before & After Restoration Balm into the briar with my finger tips and a shoe brush to get into the nooks and crannies. I let it sit on the bowl for 10 minutes and then buffed it off with a paper towel and soft cloth. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I restore.

I set the bowl aside and sanded the stem with 320-3500 grit sanding pads. I wiped it down after each pad with Obsidian Oil and it began to look very good.

I set the bowl aside and sanded the stem with 320-3500 grit sanding pads. I wiped it down after each pad with Obsidian Oil and it began to look very good. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. Once again, I wiped it down between each pad with Obsidian Oil. I further polished it with Before and After Stem Polish – both Fine and Extra Fine. It looked very good.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. Once again, I wiped it down between each pad with Obsidian Oil. I further polished it with Before and After Stem Polish – both Fine and Extra Fine. It looked very good.

I am excited to be on the homestretch with beautiful James Upshall Sandblast Square Shank 6FH Dublin. This is the part I look forward to when it all comes back together, polished and waxed. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The beautiful sandblast finish looks really good with the interesting patterns standing out on the shape. The dark stained sandblast and the polished black vulcanite went really well together. This James Upshall Long, Square Shank Dublin was another fun pipe to work on thanks to Jeff’s cleanup work. It really has that classic English Charatan look that catches the eye. The combination of various brown stains really makes the pipe look attractive. It is another comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 35 grams/1.23 ounces. This one will soon be on the British Pipe Makers Section of the rebornpipes store. Let me know if you are interested in adding it to your rack. Thanks for reading this blog and my reflections on the pipe while I worked on it.

I am excited to be on the homestretch with beautiful James Upshall Sandblast Square Shank 6FH Dublin. This is the part I look forward to when it all comes back together, polished and waxed. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The beautiful sandblast finish looks really good with the interesting patterns standing out on the shape. The dark stained sandblast and the polished black vulcanite went really well together. This James Upshall Long, Square Shank Dublin was another fun pipe to work on thanks to Jeff’s cleanup work. It really has that classic English Charatan look that catches the eye. The combination of various brown stains really makes the pipe look attractive. It is another comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 35 grams/1.23 ounces. This one will soon be on the British Pipe Makers Section of the rebornpipes store. Let me know if you are interested in adding it to your rack. Thanks for reading this blog and my reflections on the pipe while I worked on it.