by Steve Laug

A while back I was asked by a customer and friend, Jack to take on some projects for him. I have worked on a few pipes for him over the years so we seem to have a standing agreement that I will clean up his pipes. This time he sent a batch containing 11 pipes – six Bertrams, an Arlington, a GBD, an old WDC Triangle Bakelite and one marked Texaco. All of them were in various conditions and would need different types of work. I took a photo of the pipes before I started working on them. He sent them to me and evidently, I cannot count. There was a 12th bowl sans stem in the box that was a Citation Imported Briar. After finishing the first seven pipes I was kind of excited that the light at end of the tunnel was showing. I went through the box to see what I had left to work on. There was a large Bertram Billiard and two Bertram Bent Billiards (needed restemming) and sitting at the bottom was a lonely bowl without a stem. It had a threaded mortise so it would have originally had a stinger. I decided to take a break from the Bertrams and work on this one next. It was a slightly bent apple or perhaps an author bowl that needed to be restemmed. This is more complicated that fitting a tenon as you will see in the unfolding tale below. This pipe is literally number 12 from Jack’s 11 pipes (that is correct, I cannot count evidently). It is a lightly used, dull bowl that is stamped on the left side and read CITATION [over] Imported Briar. The finish was dusty but otherwise quite clean. The bowl was clean of cake and lava build up and only dust had gathered in the bottom of the bowl. There was no stem so I would I would need to fit one with a stinger style tenon. Like the rest of the pipes that Jack sent, this one had promise that should come alive with a cleanup and new stem. I took photos of the bowl before I started his cleanup work.

After finishing the first seven pipes I was kind of excited that the light at end of the tunnel was showing. I went through the box to see what I had left to work on. There was a large Bertram Billiard and two Bertram Bent Billiards (needed restemming) and sitting at the bottom was a lonely bowl without a stem. It had a threaded mortise so it would have originally had a stinger. I decided to take a break from the Bertrams and work on this one next. It was a slightly bent apple or perhaps an author bowl that needed to be restemmed. This is more complicated that fitting a tenon as you will see in the unfolding tale below. This pipe is literally number 12 from Jack’s 11 pipes (that is correct, I cannot count evidently). It is a lightly used, dull bowl that is stamped on the left side and read CITATION [over] Imported Briar. The finish was dusty but otherwise quite clean. The bowl was clean of cake and lava build up and only dust had gathered in the bottom of the bowl. There was no stem so I would I would need to fit one with a stinger style tenon. Like the rest of the pipes that Jack sent, this one had promise that should come alive with a cleanup and new stem. I took photos of the bowl before I started his cleanup work.

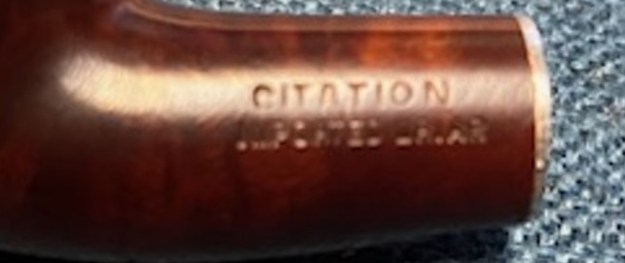

I took a photo of the stamping on the left side of the shank. It reads as noted above. It is clear and readable.

I took a photo of the stamping on the left side of the shank. It reads as noted above. It is clear and readable. I did some digging on the make of the Citation pipe and found two possible leads – one made by Savinelli in Italy and one made by Alpha in Israel. Both had the country of origin stamped on them and both used a script for the name of the brand. This one is block letters so I am left with a bit of a mystery. If anyone can give more clarity to this please leave a comment below. Thanks.

I did some digging on the make of the Citation pipe and found two possible leads – one made by Savinelli in Italy and one made by Alpha in Israel. Both had the country of origin stamped on them and both used a script for the name of the brand. This one is block letters so I am left with a bit of a mystery. If anyone can give more clarity to this please leave a comment below. Thanks.

I started my work on the bowl by cleaning out the shank, the airway and the mortise with alcohol, cotton swabs, hard bristle and soft bristle pipe cleaners. It was a very dirty pipe which just meant that it had really been enjoyed by the previous pipe man. Since I was restemming the pipe I would do the clean out on the new stem when I got it. I scrubbed the exterior of the bowl and shank with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the dusty inside of the bowl with the soap. I rinsed the briar with warm water to remove the grime and debris of the scrubbing. It looked significantly better after the scrubbing.

I scrubbed the exterior of the bowl and shank with a tooth brush and undiluted Murphy’s Oil Soap. I scrubbed the dusty inside of the bowl with the soap. I rinsed the briar with warm water to remove the grime and debris of the scrubbing. It looked significantly better after the scrubbing.

I paused from the bowl cleanup to see what I could find regarding a stem and a stinger that I could use. I found a stem that had the same diameter as the shank. It was a push stem so I cut off the tenon with a hacksaw blade.

I paused from the bowl cleanup to see what I could find regarding a stem and a stinger that I could use. I found a stem that had the same diameter as the shank. It was a push stem so I cut off the tenon with a hacksaw blade.

I have collected many stingers over the years and put them in a jar. I scavenged them from ruined stems and other places and have kept them all. I went through the jar and found the stinger I needed for this mortise. I threaded it into the shank and checked the fit. It was perfect.

I have collected many stingers over the years and put them in a jar. I scavenged them from ruined stems and other places and have kept them all. I went through the jar and found the stinger I needed for this mortise. I threaded it into the shank and checked the fit. It was perfect. Now I had the proper stem and the proper stinger tenon. Now I had to put those pieces together in such a way that the stem lined up properly with the shank. I drilled out the airway in the stem with my cordless drill. I checked the fit of the threaded end of the stinger in the airway and it fit well. I cleaned the inside of the airway with alcohol and pipe cleaners so that it would be clean(no photos taken). I threaded it into the shank and marked the top. I unscrewed it and coated it with a layer of all purpose glue. I turned it into the stem end and set it aside to dry. The glue did not cure hard enough and when I turned it into the shank it popped loose. I reglued it with black CA rubberized glue and set aside once again.

Now I had the proper stem and the proper stinger tenon. Now I had to put those pieces together in such a way that the stem lined up properly with the shank. I drilled out the airway in the stem with my cordless drill. I checked the fit of the threaded end of the stinger in the airway and it fit well. I cleaned the inside of the airway with alcohol and pipe cleaners so that it would be clean(no photos taken). I threaded it into the shank and marked the top. I unscrewed it and coated it with a layer of all purpose glue. I turned it into the stem end and set it aside to dry. The glue did not cure hard enough and when I turned it into the shank it popped loose. I reglued it with black CA rubberized glue and set aside once again.

Once the tenon hardened in the stem I screwed it onto the shank and lined it all up to make sure it was straight! It was perfect! I “painted” the stem surface with the flame of a lighter to soften the vulcanite so I could bend it. Once it was flexible I set the bowl rim top down and pressed down on the stem where I wanted the bend to be and let it cool in that position.

Once the tenon hardened in the stem I screwed it onto the shank and lined it all up to make sure it was straight! It was perfect! I “painted” the stem surface with the flame of a lighter to soften the vulcanite so I could bend it. Once it was flexible I set the bowl rim top down and pressed down on the stem where I wanted the bend to be and let it cool in that position. Since it was in decent condition after cleaning it I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each pad with a damp cloth to remove the sanding debris. It looked very good once I finished.

Since it was in decent condition after cleaning it I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit sanding pads. I wiped it down after each pad with a damp cloth to remove the sanding debris. It looked very good once I finished.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I set the bowl aside and turned my attention back to the vulcanite stem. I sanded it with 220 grit sandpaper to remove the oxidation and smooth out the tooth chatter on the surface. It looked better.

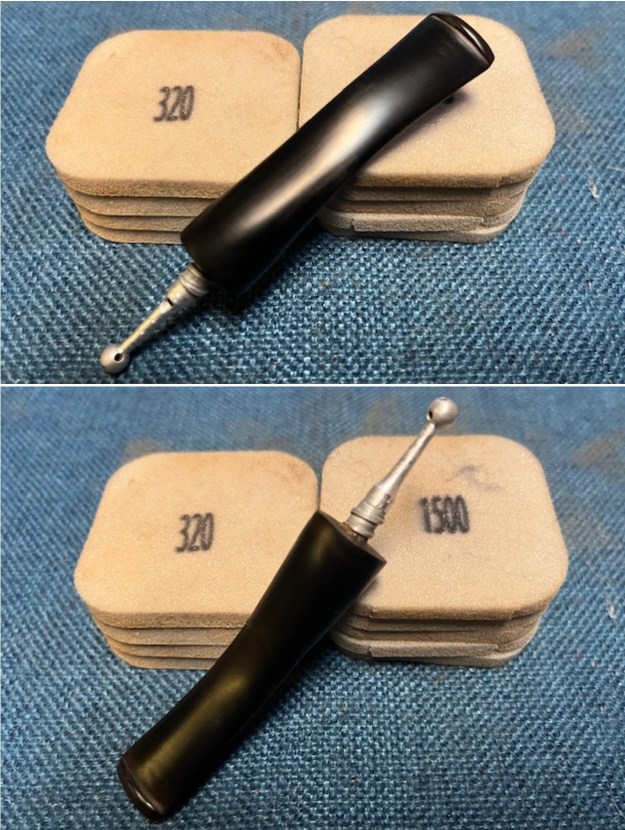

I set the bowl aside and turned my attention back to the vulcanite stem. I sanded it with 220 grit sandpaper to remove the oxidation and smooth out the tooth chatter on the surface. It looked better. I sanded the surface of the vulcanite with the 2 x 2-inch sanding pads – 320-3500 grit pads to clean up the sanding marks and remaining casting marks on the stem surface. By the final 3500 grit pad the stem started to really shine.

I sanded the surface of the vulcanite with the 2 x 2-inch sanding pads – 320-3500 grit pads to clean up the sanding marks and remaining casting marks on the stem surface. By the final 3500 grit pad the stem started to really shine. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished the stem with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a coat of Obsidian Pipe Stem Oil. It works to protect the stem from oxidizing. I set it aside to dry.

I am excited to finish this Citation Bent Apple/Author with a newly fit taper stem and metal stinger tenon. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and then by hand with a microfibre cloth to deepen it. It is fun to see what the polished bowl looks like with beautiful grain all around it. The polished grain on the pipe looks great with the new black vulcanite stem. This Citation Bent Apple/Author is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 43 grams/1.52 ounces. It is another beautiful pipe that I will send to Jack after I finish working on the other 4 pipes. I look forward to hear what he thinks of this next beauty. It should be a great smoking pipe.

I am excited to finish this Citation Bent Apple/Author with a newly fit taper stem and metal stinger tenon. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine and then by hand with a microfibre cloth to deepen it. It is fun to see what the polished bowl looks like with beautiful grain all around it. The polished grain on the pipe looks great with the new black vulcanite stem. This Citation Bent Apple/Author is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 43 grams/1.52 ounces. It is another beautiful pipe that I will send to Jack after I finish working on the other 4 pipes. I look forward to hear what he thinks of this next beauty. It should be a great smoking pipe.

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.