by Steve Laug

The next pipe on the table is one that came to us from the group of pipes that Jeff and I purchased from a fellow selling an estate collection in Long Island, New York, USA on 04/16/2024. It is another Dunhill sandblast that is in good condition. It is stamped on a smooth panel on the underside of the shank with the shape number 35F/T followed by Dunhill [over] Tanshell. Next to that it is stamped Made in [over] England by the date number 6. After that it is stamped with a 3 in a circle [followed by] T for Tanshell. The stamping is clear and readable as noted above. The pipe has a mix of brown stains on a sandblast finish and some amazing grain that the shape follows well. The finish was dusty and oily around the nooks and crannies of the sandblast but otherwise fairly clean. There was some wear on the rim top and the front outer edge of the bowl where it had been knocked. The bowl had a thick cake and there was lava on the sandblasted rim top or edges. The taper stem was oxidized, calcified, dirty and had scratches, tooth marks and chatter ahead of the button. I took photos of the pipe to show what it looked like before I started working on it.

I took photos of the bowl and rim top to show their condition and of the stem to show the condition of both sides of the stem.

I took photos of the bowl and rim top to show their condition and of the stem to show the condition of both sides of the stem. The stamping on the underside of the shank is shown in the photo below. It looks very good and faint but readable. It reads as noted and explained above. I captured the detail in the photos below. I removed the stem and took a photo to give a sense of what the pipe looked like.

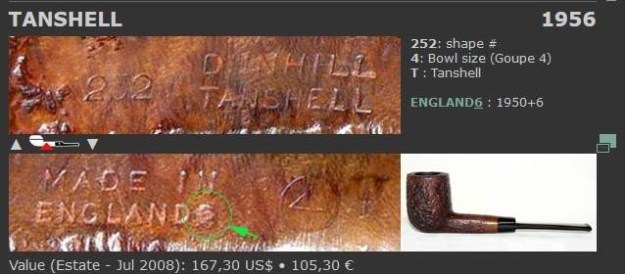

The stamping on the underside of the shank is shown in the photo below. It looks very good and faint but readable. It reads as noted and explained above. I captured the detail in the photos below. I removed the stem and took a photo to give a sense of what the pipe looked like. One of the first things I like to do is to unpack the stamping and understand each element in it. I turned to Pipephil helpful site (http://pipephil.eu/logos/en/dunhill/tanshell1.html). The stamping is interpreted as follows: The number 35 is the shape number for a Billiard. The F/T signifies a Fish Tail stem. The Tanshell stamp refers to the finish which is corroborated the T at the end of the stamping. The size of the pipe 3 in a circle is a Group 3. The 6 following the D of England gives the date the pipe.

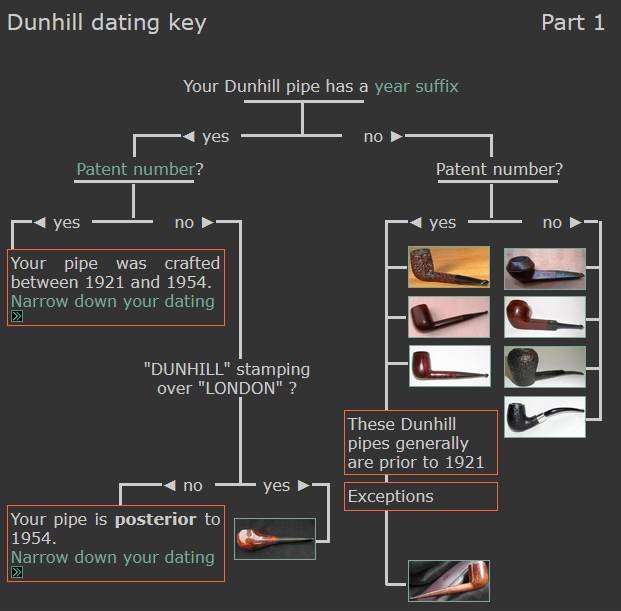

One of the first things I like to do is to unpack the stamping and understand each element in it. I turned to Pipephil helpful site (http://pipephil.eu/logos/en/dunhill/tanshell1.html). The stamping is interpreted as follows: The number 35 is the shape number for a Billiard. The F/T signifies a Fish Tail stem. The Tanshell stamp refers to the finish which is corroborated the T at the end of the stamping. The size of the pipe 3 in a circle is a Group 3. The 6 following the D of England gives the date the pipe.  Pipephil also has some helpful dating keys on the site that are basically flow charts that you can walk through to date your pipe (http://pipephil.eu/logos/en/dunhill/cledat-en1.html). I turned to Part 1 of the Dating Key and followed the chart. This pipe has a 6 following the D in England. It is the same size as the D so that took me to the section on the chart below (column one) which instructed me that the pipe could be dated as being made posterior to 1954.

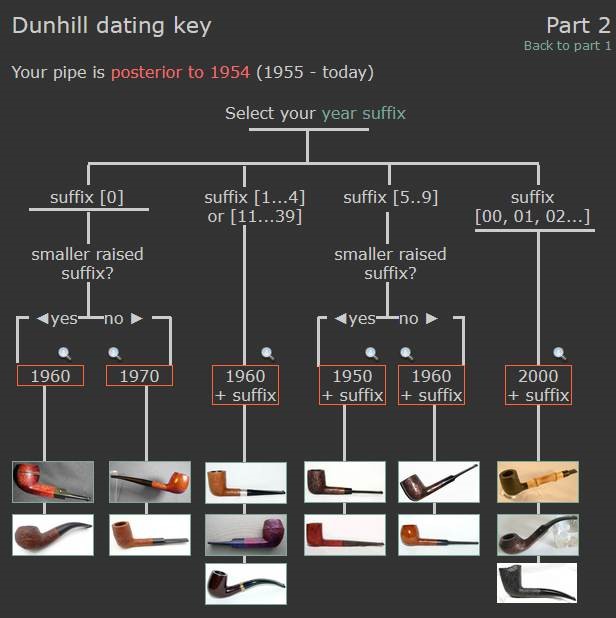

Pipephil also has some helpful dating keys on the site that are basically flow charts that you can walk through to date your pipe (http://pipephil.eu/logos/en/dunhill/cledat-en1.html). I turned to Part 1 of the Dating Key and followed the chart. This pipe has a 6 following the D in England. It is the same size as the D so that took me to the section on the chart below (column one) which instructed me that the pipe could be dated as being made posterior to 1954.  I followed the link following the “Your pipe is posterior to 1954. Narrow down your dating”. That took me to Page 2 of the dating key (http://pipephil.eu/logos/en/dunhill/cledat-en1a.html). The third column (suffix 5…9) led me to the section with a 6 after the D in England that is the same size as the D. There was a directive for dating the pipe spelled out as follows: 1960 + suffix which gives the pipe a date of 1966.

I followed the link following the “Your pipe is posterior to 1954. Narrow down your dating”. That took me to Page 2 of the dating key (http://pipephil.eu/logos/en/dunhill/cledat-en1a.html). The third column (suffix 5…9) led me to the section with a 6 after the D in England that is the same size as the D. There was a directive for dating the pipe spelled out as follows: 1960 + suffix which gives the pipe a date of 1966. I then turned to Pipedia’s section on Dunhill Root Briar to get a bit of background on the Dunhill finishes (https://pipedia.org/wiki/Dunhill#Root_Briar). I quote:

I then turned to Pipedia’s section on Dunhill Root Briar to get a bit of background on the Dunhill finishes (https://pipedia.org/wiki/Dunhill#Root_Briar). I quote:

Tanshell

The first lot was distributed in 1952 (usually made using Sardinian briar). The prototype was called “Root Shell “, produced in 1951. The Tanshell is a light tan sandblast. Sardinian briar was used for this sandblast. There is a distinct contrast in the sandblasts using Sardinian as opposed to Algerian briar. The Sardinian is much denser and much harder. The resulting pattern, when blasted, is far more even and regular both in terms of the surface texture and the finish.

The TanShell was Dunhill’s fourth finish and its first major post-war line addition. Introduced in 1951/1952 the TanShell was a naturally stained sandblasted pipe made exclusively from Sardinian briar through the 1960s. The TanShell apparently was not simply a light stained Shell but rather was also the product of “certain processes [unrevealed] not previously employed.” Initially, it appears that the pipe was to be named the Root Shell and a stamp to that effect was ordered and received by Dunhill in May 1951. Ultimately, however, the name TanShell was settled upon but the stamp for the TanShell name was not received by Dunhill until the beginning of December. Thus while the Tanshell was in production in 1951 it appears that most if not all TanShells made in that year did not enter into retail distribution until 1952 and were given a 1952 date code. Loring, J. C., The Dunhill Briar Pipe, The Patent Years and After (self-published, Chicago, 1998).

- See more examples here: Dunhill Tanshell

- See more about the patents applied here: Shellbriar & Tanshell, Patents 1917-1954

I have also included a chart from the site from Dunhill spelling out the Standard Pipe Finishes and giving short information and a timeline.  I turned to work on the pipe itself. I reamed the bowl with a PipNet reamer using the second cutting head. I took the cake back to bare briar. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife and then sanded the bowl walls with a piece of dowel wrapped with 220 grit sandpaper. The bowl looked very good at this point there were no burn marks and only light checking on the walls.

I turned to work on the pipe itself. I reamed the bowl with a PipNet reamer using the second cutting head. I took the cake back to bare briar. I cleaned up the reaming with a Savinelli Fitsall Pipe Knife and then sanded the bowl walls with a piece of dowel wrapped with 220 grit sandpaper. The bowl looked very good at this point there were no burn marks and only light checking on the walls.

I cleaned out the inside of the shank, mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners to remove the tars and oils in them both. I used a lot of both pipe cleaners and cotton swabs to clean them as they were both very dirty.

I cleaned out the inside of the shank, mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners to remove the tars and oils in them both. I used a lot of both pipe cleaners and cotton swabs to clean them as they were both very dirty. Before I scrubbed the externals of the bowl I decided to smooth out some of the roughness on the front and the back side of the outer edge. I cleaned up the outer edge with a brass bristle wire brush. I put a few drops of clear CA glue in the roughest areas of the damaged edges on the front and the back and added some briar dust to the finish. My goal was not to rebuild the edges but to rather smooth out the damage and remove the torn and rough edges. I worked it over again with a wire brush to knock of the excess. I would do some more of that after I cleaned the exterior.

Before I scrubbed the externals of the bowl I decided to smooth out some of the roughness on the front and the back side of the outer edge. I cleaned up the outer edge with a brass bristle wire brush. I put a few drops of clear CA glue in the roughest areas of the damaged edges on the front and the back and added some briar dust to the finish. My goal was not to rebuild the edges but to rather smooth out the damage and remove the torn and rough edges. I worked it over again with a wire brush to knock of the excess. I would do some more of that after I cleaned the exterior.

I scrubbed the surface of the briar with undiluted Murphy’s Oil Soap and a tooth brush. I worked over the rim top and the damaged areas on the front and back of the bowl. I rinsed off the bowl with warm running water to remove the grime. Once it was finished it looked much better.

I scrubbed the surface of the briar with undiluted Murphy’s Oil Soap and a tooth brush. I worked over the rim top and the damaged areas on the front and back of the bowl. I rinsed off the bowl with warm running water to remove the grime. Once it was finished it looked much better.

I worked over the surface of the bowl and the rim top with the brass bristle wire brush once again. That included the rim top and the sides of the bowl and shank. It looked much better at this point.

I worked over the surface of the bowl and the rim top with the brass bristle wire brush once again. That included the rim top and the sides of the bowl and shank. It looked much better at this point.

At this point I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips and a horsehair shoe brush to work it into the nooks and crannies of the sandblast finish. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

At this point I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips and a horsehair shoe brush to work it into the nooks and crannies of the sandblast finish. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I set the bowl aside and turned my attention to the stem. I scrubbed the oxidation, calcification and debris off the surface of the vulcanite with Soft Scrub on cotton pads. It looked much better once it was finished. I sanded out the majority of the tooth marks with 220 grit sandpaper. I filled in the light tooth marks that remained with black CA glue. I set the stem aside to let the repairs cure. Once they cured I sanded them smooth with 220 grit sandpaper.

I set the bowl aside and turned my attention to the stem. I scrubbed the oxidation, calcification and debris off the surface of the vulcanite with Soft Scrub on cotton pads. It looked much better once it was finished. I sanded out the majority of the tooth marks with 220 grit sandpaper. I filled in the light tooth marks that remained with black CA glue. I set the stem aside to let the repairs cure. Once they cured I sanded them smooth with 220 grit sandpaper.

I started the polishing process with 320-3500 grit sanding pads. I wiped it down after each sanding pad with a cloth impregnated with Obsidian Oil. I let it soak in.

I started the polishing process with 320-3500 grit sanding pads. I wiped it down after each sanding pad with a cloth impregnated with Obsidian Oil. I let it soak in. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. Once again I wiped it down between each pad with Obsidian Oil. I further polished it with Before and After Stem Polish – both Fine and Extra Fine. It looked very good.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. Once again I wiped it down between each pad with Obsidian Oil. I further polished it with Before and After Stem Polish – both Fine and Extra Fine. It looked very good.

This 1966 Dunhill Tanshell 35F/T Group 3 Billiard with a Taper Stem has a beautiful, unique Dunhill Sandblast finish that was deep and craggy but now slightly worn. The reddish brown finish highlights some great grain around the bowl and shank. It has some great rugged sandblast that Dunhill specialized in making. The outer edges are a bit worn but I have chosen to leave them as part of the pipe’s story. The polished black vulcanite taper stem adds to the mix. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Dunhill Tanshell 35F/T Billiard is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is .95 ounces/27 grams. Thanks for walking through the restoration with me as I worked over another beautiful pipe. If you are interested in adding it to your collection I will be adding it to the British Pipe Makers Section of the rebornpipes store. Thanks for your time.

This 1966 Dunhill Tanshell 35F/T Group 3 Billiard with a Taper Stem has a beautiful, unique Dunhill Sandblast finish that was deep and craggy but now slightly worn. The reddish brown finish highlights some great grain around the bowl and shank. It has some great rugged sandblast that Dunhill specialized in making. The outer edges are a bit worn but I have chosen to leave them as part of the pipe’s story. The polished black vulcanite taper stem adds to the mix. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Dunhill Tanshell 35F/T Billiard is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 1/8 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is .95 ounces/27 grams. Thanks for walking through the restoration with me as I worked over another beautiful pipe. If you are interested in adding it to your collection I will be adding it to the British Pipe Makers Section of the rebornpipes store. Thanks for your time.