Blog by Steve Laug

The next pipe I took out of the refurbishing box was an Oom Paul that had a lot of character and some nice grain. It was stamped on the left side with the name Dulwich over Quaint. On the right side it was stamped with the number 64. It was also stamped on the underside, horizontally at the stem shank union with the words Made in England. I have searched for information on the internet for the brand in the past and not been able to find anything helpful. In a previous blog I wrote on a pair of Dulwich Quaint pipes the only link I could find was that the shape number was an Orlik shape number. Here is the link to the other blog: https://rebornpipes.com/2016/03/13/a-rare-find-a-pair-of-fieldcraft-dulwich-quaints/

My brother took some photos of the pipe when he received it and before he had done any cleanup work on it.

He took some close up photos of the pipe. The first photo shows the top of the rim was in good shape. There was some light tars and some scratching on the surface of the rim. The second and third photos show the stamping – first the Dulwich over Quaint and then the Made in England.

He took some close up photos of the pipe. The first photo shows the top of the rim was in good shape. There was some light tars and some scratching on the surface of the rim. The second and third photos show the stamping – first the Dulwich over Quaint and then the Made in England.

Both sides of the stem looked like the photo below. There was a lot of tooth chatter and marks on the stem surface on the top and bottom. The button was worn down by teeth mid button.

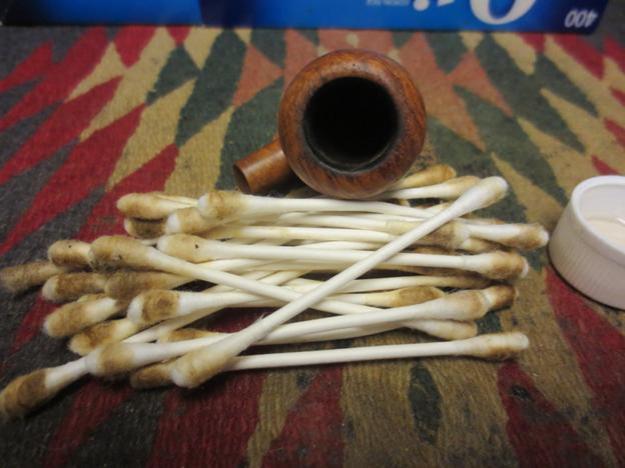

Both sides of the stem looked like the photo below. There was a lot of tooth chatter and marks on the stem surface on the top and bottom. The button was worn down by teeth mid button. My brother scrubbed the pipe with his usual mixture of Murphy’s Oil Soap and water. He rinsed the bowl with running water. He scrubbed out the internals of the pipe with pipe cleaners, cotton swabs and alcohol. When it arrived I took the following pictures to show its condition. The finish was worn and uneven all around the bowl. The shank was also unevenly finished. The finish on the rim was also worn.

My brother scrubbed the pipe with his usual mixture of Murphy’s Oil Soap and water. He rinsed the bowl with running water. He scrubbed out the internals of the pipe with pipe cleaners, cotton swabs and alcohol. When it arrived I took the following pictures to show its condition. The finish was worn and uneven all around the bowl. The shank was also unevenly finished. The finish on the rim was also worn.

I took some close up photos of the rim top to show what it looked like before I started. I took some photos of the stem surface to show the condition of the stem. It shows the tooth chatter and some mild oxidation on the stem.

I took some close up photos of the rim top to show what it looked like before I started. I took some photos of the stem surface to show the condition of the stem. It shows the tooth chatter and some mild oxidation on the stem.

I scrubbed the bowl down with acetone on cotton pads to remove the finish. I also sanded the bowl lightly with a medium grit sanding block to break up the finish that remained on the bowl. I wiped it again to remove all the finish that remained. The clean bowl is shown in the photos below.

I scrubbed the bowl down with acetone on cotton pads to remove the finish. I also sanded the bowl lightly with a medium grit sanding block to break up the finish that remained on the bowl. I wiped it again to remove all the finish that remained. The clean bowl is shown in the photos below.

I sanded out the tooth chatter and marks on the stem from the button forward. I reshaped the surface of the button with sandpaper to smooth out the tooth marks and redefine the sharp edge of the button on the top and the bottom sides.

I sanded out the tooth chatter and marks on the stem from the button forward. I reshaped the surface of the button with sandpaper to smooth out the tooth marks and redefine the sharp edge of the button on the top and the bottom sides. I removed the stinger from the end of the stem and sanded the saddle portion of the stem to smooth out the scratches.

I removed the stinger from the end of the stem and sanded the saddle portion of the stem to smooth out the scratches. I wiped down the bowl with a light coat of olive oil and hand buffed the bowl to give it a shine. The next photos show the bowl at this point.

I wiped down the bowl with a light coat of olive oil and hand buffed the bowl to give it a shine. The next photos show the bowl at this point.

I sanded the stem with micromesh sanding pads – wet sanding it with 1500-1400 grit pads and dry sanding it with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. I set it aside to dry once the final pad was used.

I sanded the stem with micromesh sanding pads – wet sanding it with 1500-1400 grit pads and dry sanding it with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. I set it aside to dry once the final pad was used.

I buffed the bowl and stem with Blue Diamond on the buffing wheel to smooth out the finish and the stem. I gave both multiple coats of carnauba wax and buffed it with a clean buffing pad. It raised a shine on the bowl and stem. I used a microfibre cloth to deepen the shine. I hand buffed it until it shone. The finished pipe is shown in the photos below. It has a wide open draw and should be a delightful smoking instrument. Thanks for looking.

I buffed the bowl and stem with Blue Diamond on the buffing wheel to smooth out the finish and the stem. I gave both multiple coats of carnauba wax and buffed it with a clean buffing pad. It raised a shine on the bowl and stem. I used a microfibre cloth to deepen the shine. I hand buffed it until it shone. The finished pipe is shown in the photos below. It has a wide open draw and should be a delightful smoking instrument. Thanks for looking.