by Kenneth Lieblich

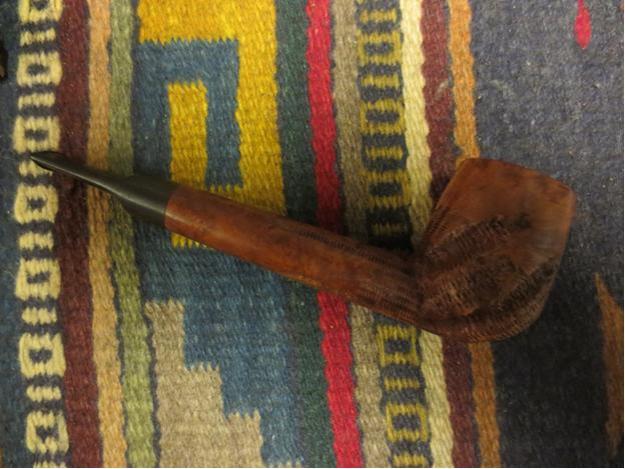

My last blog post was the restoration of an Oversize Kaywoodie and, in that article, I mentioned that it reminded me of a Custombilt. Well, lo and behold! I have a Custombilt to present to you all. I was rummaging through a box of junk (and calling it ‘junk’ is being kind) and came upon a really good-looking, substantial Lovat with a great saddle stem (which is ever-so-slightly bent). It’s a pipe that instills confidence. An interesting coincidence (or is it?) is that both the Kaywoodie and this Custombilt were made at almost exactly the same time. Read on.

As you can see, the pipe has the classic Custombilt rustication on it. There’s something quite satisfying about this rugged rustication. These marks are reminiscent of Tracy Mincer’s original work and are seen as something of a hallmark of the brand. On the left side of the shank, the markings were as follows: Custombilt [over] Imported Briar. No markings on the right side and no markings on the stem.

As you can see, the pipe has the classic Custombilt rustication on it. There’s something quite satisfying about this rugged rustication. These marks are reminiscent of Tracy Mincer’s original work and are seen as something of a hallmark of the brand. On the left side of the shank, the markings were as follows: Custombilt [over] Imported Briar. No markings on the right side and no markings on the stem.

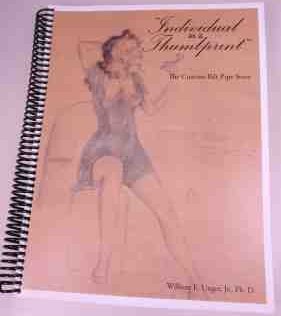

The history of Custombilt pipes is an interesting one and the most comprehensive source of information comes from Individual as a Thumbprint: The Custom-Bilt Pipe Story by Bill Unger. It is a very good book. Since the last time I worked on a Custombilt, I acquired a copy and it is an excellent resource on these pipes – as well as an entertaining read.

The history of Custombilt pipes is an interesting one and the most comprehensive source of information comes from Individual as a Thumbprint: The Custom-Bilt Pipe Story by Bill Unger. It is a very good book. Since the last time I worked on a Custombilt, I acquired a copy and it is an excellent resource on these pipes – as well as an entertaining read.

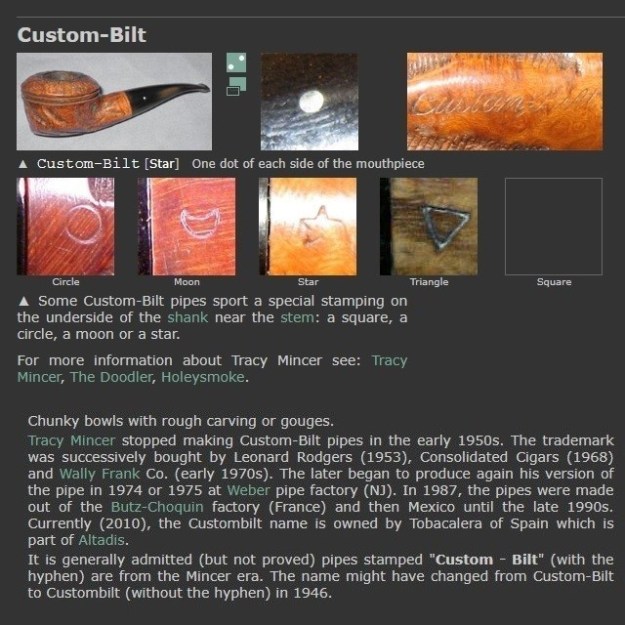

Unger’s book gives us some good information about the dating for this pipe. He displays five different logo stampings and this particular pipe corresponds to stamp number two. Unger writes:

Unger’s book gives us some good information about the dating for this pipe. He displays five different logo stampings and this particular pipe corresponds to stamp number two. Unger writes:

The second stamp, which was used during the Eugene Rich years, from 1946 through 1952 (at the latest; it could have been 1950 or 191), is also quite unmistakable. Custom-Bilt became Custombilt in 1946, and the stamp reflects the major advertising campaign that was undertaken. The script letters do not slant, but the major feature is the big, looping C, which extends over the t (although, in some cases, it extends just to the top of the t). The t has a longer cross than on the Custom-Bilt stamp, but a shorter one than would be used during the Wally Frank era. Remember that the Eugene Rich-era stamp was used on pipes still being made in [Tracy] Mincer’s Indianapolis factory.

Pipedia’s article on Custombilt consists primarily of reviews of Unger’s book. It offers a cursory view of the markings and their approximate dating. This information confirms what I found in Unger’s book. Meanwhile. Pipephil provided a bit more information on the brand, although not strictly related to my pipe. In short, I think it’s fair to say that this sturdy pipe dates from the late-1940s. Let’s get on with cleaning up this pipe. I worked on the stem first and, I must say, I was surprised at its good condition. Not too dirty, not beat up at all.

Let’s get on with cleaning up this pipe. I worked on the stem first and, I must say, I was surprised at its good condition. Not too dirty, not beat up at all. I wiped the outside with some oil soap on some cotton pads. Then I cleaned out the inside with pipe cleaners and isopropyl alcohol. The stem had a bit of oxidation, so I let it soak overnight in pipe stem oxidation remover. The following day, I cleaned all of the de-oxidizing mess off with a toothbrush. The oxidation had migrated to the surface and I scrubbed with SoftScrub on some cotton pads to remove the leftover oxidation. The stem turned out very well.

I wiped the outside with some oil soap on some cotton pads. Then I cleaned out the inside with pipe cleaners and isopropyl alcohol. The stem had a bit of oxidation, so I let it soak overnight in pipe stem oxidation remover. The following day, I cleaned all of the de-oxidizing mess off with a toothbrush. The oxidation had migrated to the surface and I scrubbed with SoftScrub on some cotton pads to remove the leftover oxidation. The stem turned out very well.

I then used all nine Micromesh pads (1,500 through 12,000 grit) all over the saddle stem to remove any scratch marks and make it smooth and lovely. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

I then used all nine Micromesh pads (1,500 through 12,000 grit) all over the saddle stem to remove any scratch marks and make it smooth and lovely. I also used Obsidian Pipe Stem Oil in between each pad scrubbing. All that finished, I set the stem aside and I began work on the very dirty stummel.

All that finished, I set the stem aside and I began work on the very dirty stummel. Firstly, I decided to ream out the bowl. This is a large bowl and I used the PipNet Reamer’s biggest blade to remove the built-up cake, and followed that with 220-grit sandpaper taped to a couple of dowels to eliminate as much as I could. I took the chamber down to bare briar, as I wanted to ensure there were no hidden flaws in the wall. Fortunately, there were none. As the photos show, there was quite a mound of debris.

Firstly, I decided to ream out the bowl. This is a large bowl and I used the PipNet Reamer’s biggest blade to remove the built-up cake, and followed that with 220-grit sandpaper taped to a couple of dowels to eliminate as much as I could. I took the chamber down to bare briar, as I wanted to ensure there were no hidden flaws in the wall. Fortunately, there were none. As the photos show, there was quite a mound of debris. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and lemon-infused isopropyl alcohol. It was ridiculously dirty and took up the country’s supply of cotton to get it clean. To exorcise the demons of tobaccos past, I decided to de-ghost the pipe. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. I followed that up by cleaning the insides with some dish soap and tube brushes. Spic and span after that.

I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and lemon-infused isopropyl alcohol. It was ridiculously dirty and took up the country’s supply of cotton to get it clean. To exorcise the demons of tobaccos past, I decided to de-ghost the pipe. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. I followed that up by cleaning the insides with some dish soap and tube brushes. Spic and span after that.

There was still quite a bit of debris on the ample rim and it was time to address it. I took a piece of machine metal and meticulously scraped away the cake without affecting the finish of the wood. This quite a while – but it is most certainly worth it. Following that, I used some oil soap and a toothbrush to clean up the balance of the rim – especially the grooves of the rustication. I was really pleased with the results.

There was still quite a bit of debris on the ample rim and it was time to address it. I took a piece of machine metal and meticulously scraped away the cake without affecting the finish of the wood. This quite a while – but it is most certainly worth it. Following that, I used some oil soap and a toothbrush to clean up the balance of the rim – especially the grooves of the rustication. I was really pleased with the results. Then I sanded the stummel down with the Micromesh pads (1,500 through 12,000 grit). The smooth areas got all nine pads, whereas the rusticated areas on received only the last three or four. I then coated the pipe with restoration balm and let it sit for 20 minutes or so, before polishing with a microfibre cloth and a horsehair brush. The balm does wonderful things to the wood and makes the whole stummel sing.

Then I sanded the stummel down with the Micromesh pads (1,500 through 12,000 grit). The smooth areas got all nine pads, whereas the rusticated areas on received only the last three or four. I then coated the pipe with restoration balm and let it sit for 20 minutes or so, before polishing with a microfibre cloth and a horsehair brush. The balm does wonderful things to the wood and makes the whole stummel sing.

Finally, I took it to the buffer and applied some White Diamond and a few coats of Conservator’s Wax. The lovely shine made the wood very attractive. This is a very handsome pipe and will provide many years of smoking pleasure.

Finally, I took it to the buffer and applied some White Diamond and a few coats of Conservator’s Wax. The lovely shine made the wood very attractive. This is a very handsome pipe and will provide many years of smoking pleasure. This handsome Custombilt Lovat looks fantastic again and is ready to be enjoyed again by the next owner! I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘American’ pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 7 in. (177 mm); height 2⅛ in. (53 mm); bowl diameter 1⅝ in. (41 mm); chamber diameter ⅞ in. (22 mm). The weight of the pipe is 2¼ oz. (65 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

This handsome Custombilt Lovat looks fantastic again and is ready to be enjoyed again by the next owner! I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘American’ pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 7 in. (177 mm); height 2⅛ in. (53 mm); bowl diameter 1⅝ in. (41 mm); chamber diameter ⅞ in. (22 mm). The weight of the pipe is 2¼ oz. (65 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.