by Steve Laug

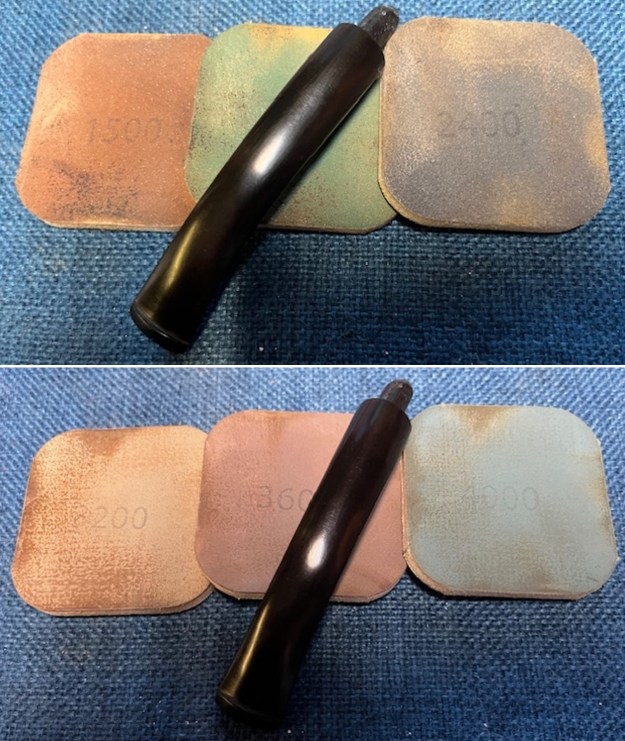

Back in January I received an email from Robert with a group 12 pipes that needed to be restored in various ways from cleanup to restemming. I chose to work on the second of the Cherrywood pipes next. It is a nice-looking Cherrywood Bent Octagonal Bowled Billiard. The bowl and shank had bark on the outside. The bowl has peeled striped around the octagon on every other flat side. The rim top and the base of the bowl were both smooth without bark. The bowl had been reamed at some time so there was no cake in it. The rim top had an overflow of lava on it and some darkening around the inner edge. The underside of the bowl was dirty but it was stamped ROPP [over] De Luxe [over] France. Underneath that what the shape number 804. The stem had no logo on it. It had light tooth marks and tooth chatter on the top and underside ahead of the button. I took some photos of the pipe to show its condition before I started my work on it.

The relatively clean bowl looks quite good. There was some thick lava on the rim top and some lava build up on the inner edge of the bowl. It looked to be in good condition other than the lava and darkening. The vulcanite taper stem was dirty, lightly oxidized and has light tooth chatter and marks on both sides. I took photos of the bowl, rim top and the stem to show the condition of both.

The relatively clean bowl looks quite good. There was some thick lava on the rim top and some lava build up on the inner edge of the bowl. It looked to be in good condition other than the lava and darkening. The vulcanite taper stem was dirty, lightly oxidized and has light tooth chatter and marks on both sides. I took photos of the bowl, rim top and the stem to show the condition of both. There was stamping on the heel of the bowl that was clear and readable. It read as noted above. I took a photo of the pipe with the stem removed to show the proportion of this pipe. It is a classic Ropp Cherrywood.

There was stamping on the heel of the bowl that was clear and readable. It read as noted above. I took a photo of the pipe with the stem removed to show the proportion of this pipe. It is a classic Ropp Cherrywood. I wanted to refresh my memory on the brand so I turned for a short, quick summary to Pipephil (http://www.pipephil.eu/logos/en/logo-ropp.html). I have included the pertinent information from that site below:

I wanted to refresh my memory on the brand so I turned for a short, quick summary to Pipephil (http://www.pipephil.eu/logos/en/logo-ropp.html). I have included the pertinent information from that site below:

Brand created by Eugène-Léon Ropp (1830 – 1907) and continued throughout 3 generations. “GBA Synergie” run by Bernard Amiel (†2008) bought back Ropp in 1988 and owned it until 1991. The company was taken over by Cuty-Fort Entreprises (Chacom, Vuillard, Jean Lacroix…) in 1994.

I also turned to Pipedia to see if there was any additional information that would be helpful (https://pipedia.org/wiki/Ropp). I quote the portion of the article on the Cherrywood pipes.

Eugène-Léon Ropp (1830 – 1907) had acquired a patent for a cherrywood pipe (wild cherry, lat.: Prunus avium) in 1869. In 1870 he established a workshop to manufacture such pipes in Büssingen (Bussang, Vosges mountains). Around 1893 the business moved into the former mill of Sicard (part of the community of Baume-les-Dames – Département Doubs, Upper Burgundy – from 1895 on)… Even though cherrywood pipes were the mainstay of Ropp until the company finally closed down in September 1991. The company was taken over by Cuty-Fort Entreprises (Chacom, Jeantet, Vuillard, Jean Lacroix…) in 1994.

The pipe thus was made in France sometime prior to the closure in 1991. It is made from wild cherry and was a specialty of Ropp. I have worked on quite a few over the years but I had forgotten all the dates and information. Now it was time to work on the pipe.

I turned to work on the pipe itself. The shank was loose in the bowl so I reglued it with all purpose white glue. I used a tooth pick to press it into the grooves around the junction and set it aside to cure.

I worked over rim top and inner edge of the bowl. I used a folded piece of 220 grit sandpaper to smooth out the damage and darkening on the smooth rim top and inner edge of the bowl. It looked much better once the debris was removed.

I worked over rim top and inner edge of the bowl. I used a folded piece of 220 grit sandpaper to smooth out the damage and darkening on the smooth rim top and inner edge of the bowl. It looked much better once the debris was removed.  I sanded the walls of the bowl smooth with a piece of dowel wrapped with a piece of 220 grit sandpaper. The walls smoothed out very well.

I sanded the walls of the bowl smooth with a piece of dowel wrapped with a piece of 220 grit sandpaper. The walls smoothed out very well. I scrubbed the bowl exterior with a tooth brush and undiluted Murphy’s Oil Soap to clean the debris and oils and tars in the cherry bark finish. I rinsed it with clean warm water and dried it off with a soft cotton cloth.

I scrubbed the bowl exterior with a tooth brush and undiluted Murphy’s Oil Soap to clean the debris and oils and tars in the cherry bark finish. I rinsed it with clean warm water and dried it off with a soft cotton cloth.

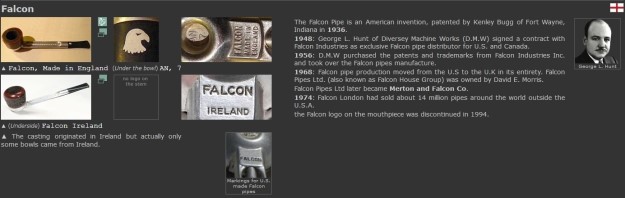

I polished the smooth rim top, four panels on the sides and heel of the bowl with 1500-12000 grit micromesh sanding pads. It smoothed out the finish very well and removed much of the damage on the rim top, smooth panels and the scratching around the stamping on the heel.

I polished the smooth rim top, four panels on the sides and heel of the bowl with 1500-12000 grit micromesh sanding pads. It smoothed out the finish very well and removed much of the damage on the rim top, smooth panels and the scratching around the stamping on the heel.

I cleaned out the mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. I was able to remove the grime and oils in the shank and the airway in the stem.

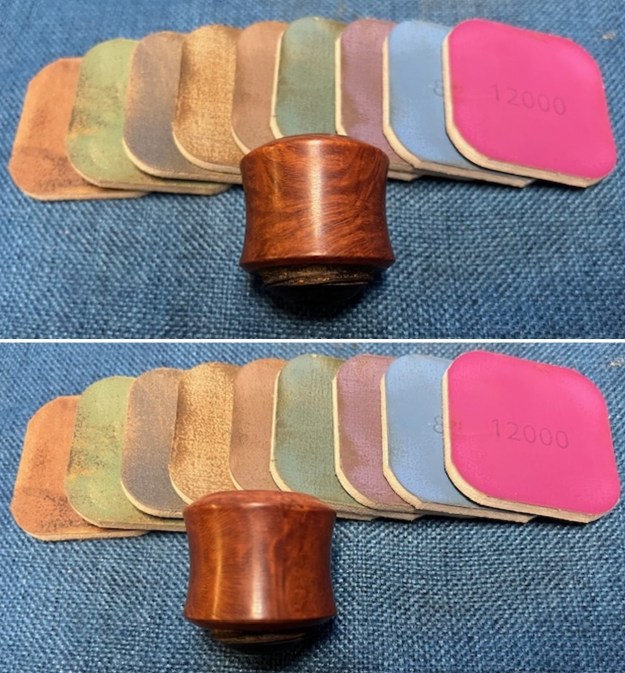

I cleaned out the mortise and airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. I was able to remove the grime and oils in the shank and the airway in the stem. I worked some Before & After Restoration Balm into the surface of the bowl and shank with my fingertips to clean, enliven and protect the wood. I let the balm sit for 15 minutes and then buffed it off with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the bowl and shank with my fingertips to clean, enliven and protect the wood. I let the balm sit for 15 minutes and then buffed it off with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

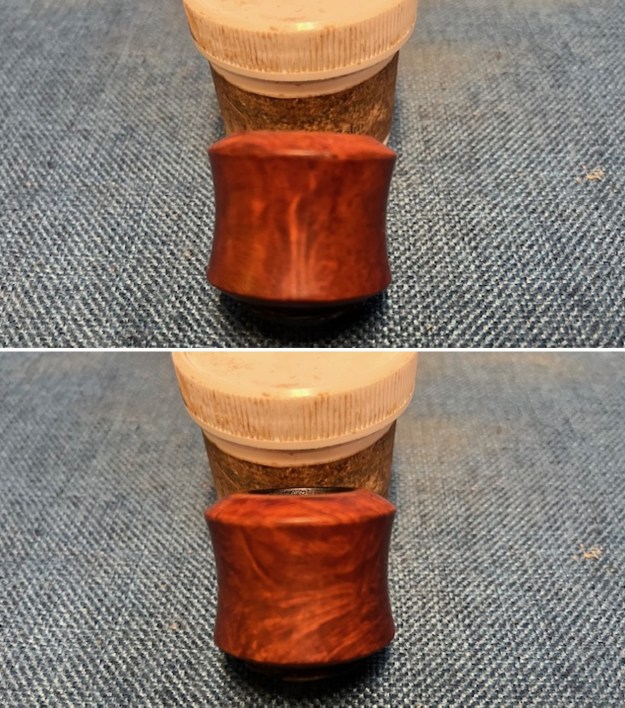

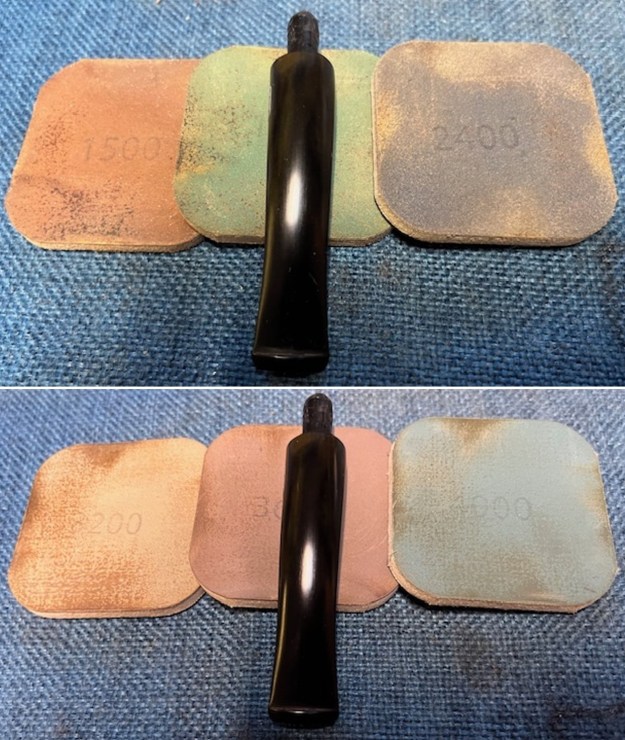

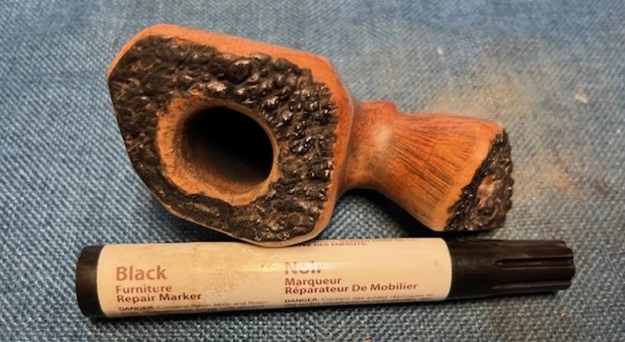

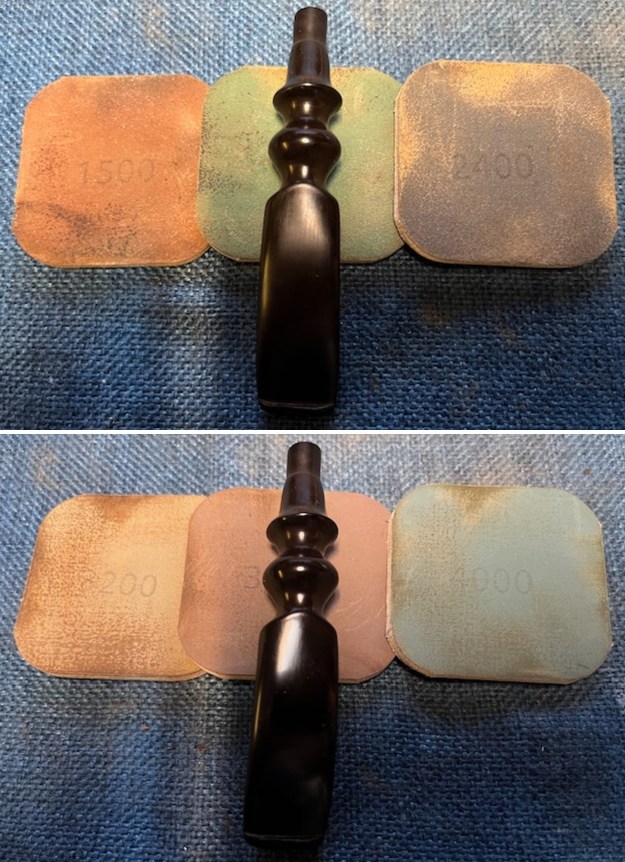

I set the bowl aside and turned my attention to the stem. I sanded the stem with 320-3500 grit sanding pads to further blend in the remnants of the tooth marks and chatter on the stem and to remove the residual light oxidation. I am happy with the way that it looked at this point.

I set the bowl aside and turned my attention to the stem. I sanded the stem with 320-3500 grit sanding pads to further blend in the remnants of the tooth marks and chatter on the stem and to remove the residual light oxidation. I am happy with the way that it looked at this point. I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Ropp De Luxe Cherrywood 804 Octagonal Bent Billiard with a vulcanite taper stem has a cherrywood bark finish with a smooth rim top and bowl heel. The bark covered Cherrywood pipe is what makes Ropp pipes stand out. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Ropp De Luxe Cherrywood Octagonal Billiard is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: 1 inch. The weight of the pipe is 2.36 ounces/66 grams. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be sending it back to Robert once I finish the other 6 pipes he sent me to restore. I look forward to hearing what he thinks of this beauty. Thanks for your time.

This Ropp De Luxe Cherrywood 804 Octagonal Bent Billiard with a vulcanite taper stem has a cherrywood bark finish with a smooth rim top and bowl heel. The bark covered Cherrywood pipe is what makes Ropp pipes stand out. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel being careful to not buff the stamping. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Ropp De Luxe Cherrywood Octagonal Billiard is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ¾ inches, Height: 2 inches, Outside diameter of the bowl: 1 ¾ inches, Chamber diameter: 1 inch. The weight of the pipe is 2.36 ounces/66 grams. Thanks for walking through the restoration with me as I worked over another beautiful pipe. I will be sending it back to Robert once I finish the other 6 pipes he sent me to restore. I look forward to hearing what he thinks of this beauty. Thanks for your time.