Blog by Steve Laug

This old Brigham One Dot was on the shelf at a Movie Studio Clearance Store – they sell old set items and materials from movies and television shows. Over the years I have found quite a few nice old pipes there for sale at a low price. I paid $12 for this one. From the photos below you can see its condition clearly. The stem was very oxidized and worse at the button end. I think that it probably had a rubber bit protector on it and it was cut off or fell of when they put it up for sale. The rustication was still crisp and sharp. The stain had faded from the top to about mid bowl and would need to be restained. The rim was tarred but not dented or damaged. The inside of the bowl was caked with an uneven cake that smelled of sweet aromatics.

I reamed the bowl and cleaned the shank and inside of the stem with pipe cleaners and cotton swabs and alcohol. I scrubbed down the exterior of the bowl and rim with Murphy’s Oil Soap to remove the grime and the tars on the rim. I have used oil soap for a long time now on the surface of pipes and found that it works best undiluted. I rub it on and rub it off. On the rim I use a soft bristle tooth brush to scrub the tars off. On this pipe since I was restaining it anyway I did not care about losing a bit of the stain or finish in the process. I finished cleaning the rim with an 1800 grit micromesh pad. I then restained it to match the colour of the smooth patch on the underside. I gave it a quick light buff with White Diamond to polish the stain.

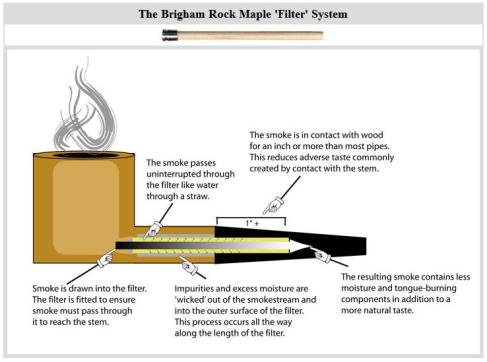

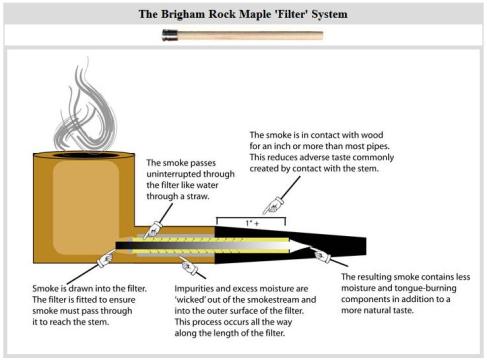

I had put the stem in a bath of Oxyclean and hot water and let it soak while I was working on the bowl. I removed it and wiped it down and resoaked it. After the second soak I sanded it with 400 and 600 grit wet dry sandpaper and then 1500-6000 grit micromesh pads to polish it. The Brighams have an aluminum shank that holds the hard rock maple filter tube. The filter tube was shot so I used a new one. The aluminum was tarry so it needed cleaning and a polish with 0000 steel wool. (The Brigham system is pictured in the graphic below.)

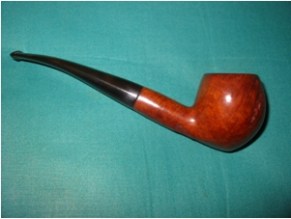

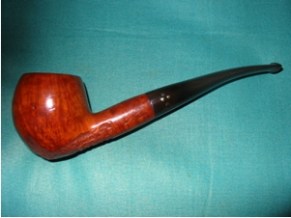

When the aluminum was clean and polished I put the pipe back together took it to the buffer and gave the stem a buff with Tripoli to take off the remnant of oxidization. Then I used some White Diamond on it to give it a clean polish. I finished buffing the whole pipe lightly with carnauba wax. The finished pipe is pictured below.