Blog by Steve Laug

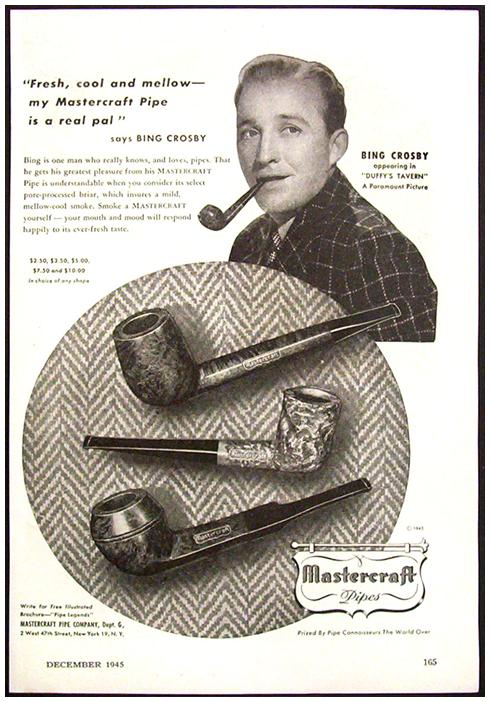

Jeff’s pipe package arrived last evening and I opened it and went through the pipes in the package. There were a lot of interesting pipes but it is hard to set them aside and keep working on Bob’s pipes. There was one that Jeff showed me on Facetime that had my attention and I wanted to work on it. The deal was clinched when I saw this pipe in person for the first time. There was something very familiar about it. I recognized both the style of the pipe and the Bing Crosby Thermostatic Filtration System. A quick search of rebornpipes revealed why it was familiar (https://rebornpipes.com/2017/07/18/a-unique-bing-crosby-thermostatic-filtration-system-pipe/). Here is a photo of the pipe I had restored before – it is an interesting Dublin. I reread the blog to remind myself of the history and background on the brand before I started work on it. Jeff took the following photos before he cleaned it up. The wire rusticated finish on the bowl and shank were filthy and filled in with grime and dust. The bowl had a thick cake lining the walls and there was some tobacco stuck in the cake. The rim top also had some lava overflow into the grooves of the rustication. The finish on the shank was also very dirty and some of the varnish was peeling off the wood. Many of the air holes in the shank were plugged. The aluminum end to the shank was in good condition. The shank slides off the stem and tube that is inside the shank. The internals were dirty but they were a Balsa wood filter that was connected to the stem. Surrounding the filter was an aluminum tube. The stem was oxidized with tooth chatter on both sides. The stem twists from side to side allowing the pipe smoker to adjust the airflow. With some clean up this rusticated Lovat will make a great partner to the long shank Dublin shown above.

Jeff took the following photos before he cleaned it up. The wire rusticated finish on the bowl and shank were filthy and filled in with grime and dust. The bowl had a thick cake lining the walls and there was some tobacco stuck in the cake. The rim top also had some lava overflow into the grooves of the rustication. The finish on the shank was also very dirty and some of the varnish was peeling off the wood. Many of the air holes in the shank were plugged. The aluminum end to the shank was in good condition. The shank slides off the stem and tube that is inside the shank. The internals were dirty but they were a Balsa wood filter that was connected to the stem. Surrounding the filter was an aluminum tube. The stem was oxidized with tooth chatter on both sides. The stem twists from side to side allowing the pipe smoker to adjust the airflow. With some clean up this rusticated Lovat will make a great partner to the long shank Dublin shown above. Jeff took photos of the bowl and rim top to show the cake in the bowl and the lava build up on the edges of the bowl. The grime and grit in the wire rusticated finish were heavily built up but even so the inner and outer edges looked very good.

Jeff took photos of the bowl and rim top to show the cake in the bowl and the lava build up on the edges of the bowl. The grime and grit in the wire rusticated finish were heavily built up but even so the inner and outer edges looked very good.  Jeff took photos of the sides and heel of the bowl to show the condition of the rusticated finish. There is a lot of dust and grime on the surface of the briar but it looks pretty interesting.

Jeff took photos of the sides and heel of the bowl to show the condition of the rusticated finish. There is a lot of dust and grime on the surface of the briar but it looks pretty interesting.  Jeff took a long view photo of the smooth heel on the bowl to give a feel for the overall look of the stamped area. He also took a photo of the stamping on the heel. It reads Bing Crosby over -0- over PAT.2.838.052 over Other Pats. Pend.

Jeff took a long view photo of the smooth heel on the bowl to give a feel for the overall look of the stamped area. He also took a photo of the stamping on the heel. It reads Bing Crosby over -0- over PAT.2.838.052 over Other Pats. Pend.  Jeff took the pipe apart and took pictures of the pipe. You can see the debris in the end of the filter in the first photo. The photos that follow show different shots of the pipe parts.

Jeff took the pipe apart and took pictures of the pipe. You can see the debris in the end of the filter in the first photo. The photos that follow show different shots of the pipe parts.

Jeff took photos of the top and underside of the stem showing the tooth chatter and marks on the stem surface and wear on the edges of the button. The stem is not vulcanite if it is like the other. It seems like a mixture of rubber and plastic of some kind.

Jeff took photos of the top and underside of the stem showing the tooth chatter and marks on the stem surface and wear on the edges of the button. The stem is not vulcanite if it is like the other. It seems like a mixture of rubber and plastic of some kind.  Before I picked up my part of the restoration I went back and reread the pertinent parts of the blog mentioned above. I was particularly interested in the background information I had previously found on the brand and on the patent number itself.

Before I picked up my part of the restoration I went back and reread the pertinent parts of the blog mentioned above. I was particularly interested in the background information I had previously found on the brand and on the patent number itself.

I had found that one of my favourite go to sites, SmokingMetals had information on the brand during my previous research (http://www.smokingmetal.co.uk/pipe.php?page=114). I have included the information from the site and some photos from there as well.

Several variants, but basically the inner stem consists of a filtering device integral with the bit. The outer sleeve comes in several designs. Twisting the perforated outer stem alters the smoke flow/air mixture. These examples here under the Bing Crosby name, but another derivative came under the name of Trailblazer, by “Pipes by Lee Inc.”. The Medico Ventilator appears to incorporate the same principle. In the previous blog I dug a little deeper in the web and found that there was a thread on the Pipesmokers Forum. Here is the link if you would like to follow the entire discussion on the thread. https://pipesmokersforum.com/community/threads/a-bing-crosby.45689/. I quote two of the respondents regarding the pipe.

In the previous blog I dug a little deeper in the web and found that there was a thread on the Pipesmokers Forum. Here is the link if you would like to follow the entire discussion on the thread. https://pipesmokersforum.com/community/threads/a-bing-crosby.45689/. I quote two of the respondents regarding the pipe.

It’s my understanding that the “Swiss cheese stem” was designed to give the pipe a cooler smoke. When you twist the pipe shank it either closes the holes or opens them – thus providing a cooler or warmer smoke. I am more interested in knowing if Bing really had a hand in its design or if the whole thing was a gimmick

…SO – the filtration system is called “thermostatic” – and the wood inside the aluminum sleeve on mine definitely looks to be balsa wood. Now if I could just get one of those magnetic drying chamber thingies.

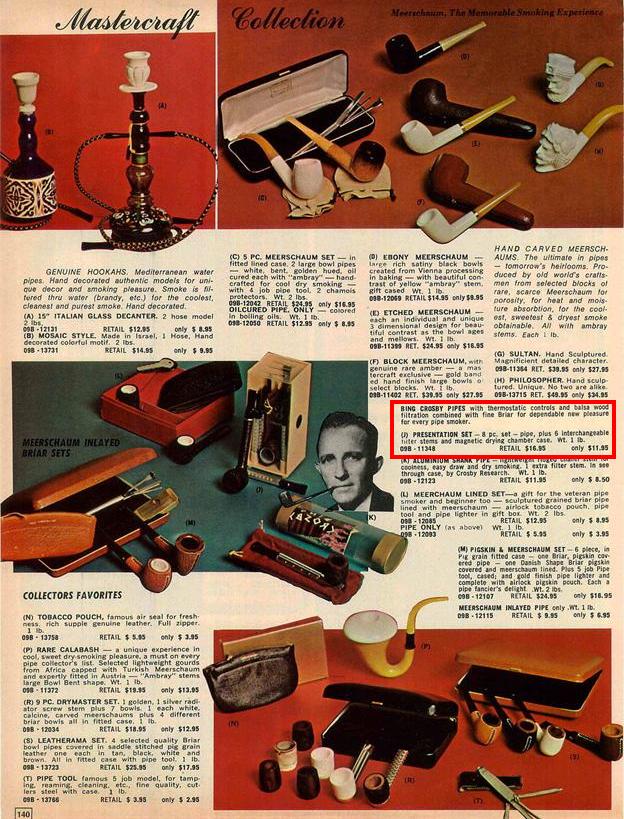

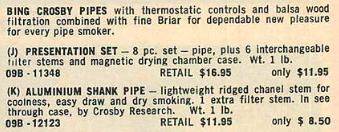

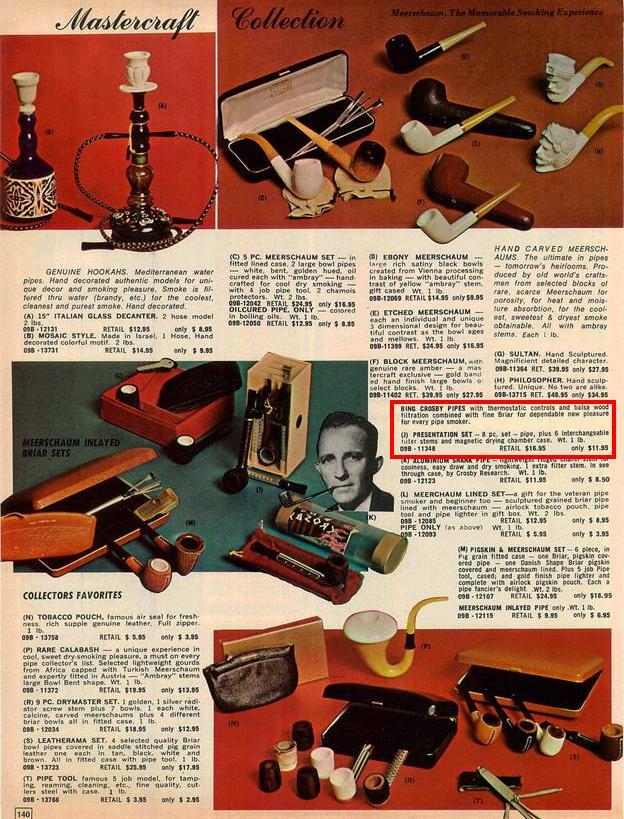

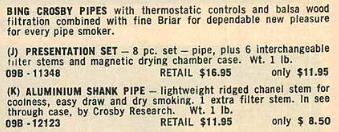

I was excited again with this pipe. In the thread quote above there were several links in the thread referring to articles and information on Bing Crosby himself and one that took me to an advertisement that appears to come from a Mastercraft Pipe Catalogue or from a magazine that included this pipe along with a selection of Mastercraft pipes. http://www.ebay.ca/itm/1971-ADVERTISEMENT-Bing-Crosby-Smoking-Pipes-Rolls-Royce-Bank-Tie-Rack-/151568646383?rmvSB=true. I have included the catalogue page and highlighted specific pipe with a red box. I included a blow up of that portion of the page so you can read it more clearly.

You can see it to the left. It reads: Bing Crosby pipes with thermostatic controls and balsa wood filtration combined with fine Briar for dependable new pleasure for every pipe smoker. In the photo item (J) and (K) show variations on the Crosby Pipe. The first is a presentation set with a pipe and 6 interchangeable filter stems and a magnetic drying chamber case where the stems and filters can be stored. Interestingly both sets bear the designation that the pipes are offered by Crosby Research.

You can see it to the left. It reads: Bing Crosby pipes with thermostatic controls and balsa wood filtration combined with fine Briar for dependable new pleasure for every pipe smoker. In the photo item (J) and (K) show variations on the Crosby Pipe. The first is a presentation set with a pipe and 6 interchangeable filter stems and a magnetic drying chamber case where the stems and filters can be stored. Interestingly both sets bear the designation that the pipes are offered by Crosby Research.

I had also previously used the patent number on the bottom of the bowl to hunt down the patent on the US Patent website. I have included the patent drawing and documentation that was submitted with the descriptions of the innovations of this pipe. The pipe was invented by Rosario Crisafulli of Jamaica Estates North, New York and was filed with the US Patent Office on July 12, 1956. The patent was granted almost two years later on June 10, 1958.

Having reread the above information and more I moved on to work on the pipe. I took some close up photos to confirm the condition of the pipe. The first shows the bowl, rim top and edges. They were in pretty good shape. There was some minor denting on the rim top. The second shows the stamping on the bottom of the bowl, confirming the information that was given above. Jeff cleaned the pipe with his usual penchant for thoroughness that I really appreciate. This one was a real mess and I did not know what to expect when I unwrapped it from his box. He reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks very good with good looking grain around the bowl and shank. Jeff soaked the stem in Before & After Deoxidizer to remove the oxidation on the stem. When the pipe arrived here in Vancouver for the second stop of its restoration tour it looked very good. I took photos before I started my part of the work.

Having reread the above information and more I moved on to work on the pipe. I took some close up photos to confirm the condition of the pipe. The first shows the bowl, rim top and edges. They were in pretty good shape. There was some minor denting on the rim top. The second shows the stamping on the bottom of the bowl, confirming the information that was given above. Jeff cleaned the pipe with his usual penchant for thoroughness that I really appreciate. This one was a real mess and I did not know what to expect when I unwrapped it from his box. He reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish looks very good with good looking grain around the bowl and shank. Jeff soaked the stem in Before & After Deoxidizer to remove the oxidation on the stem. When the pipe arrived here in Vancouver for the second stop of its restoration tour it looked very good. I took photos before I started my part of the work.

The next photos show the rim top and the stem surfaces. The rim top cleaned up amazingly and looks very new with no damage to inner or outer edges. The stem cleaned up well but the tooth chatter and marks cover both surfaces and the button. It will need to be cleaned and reshaped.

The next photos show the rim top and the stem surfaces. The rim top cleaned up amazingly and looks very new with no damage to inner or outer edges. The stem cleaned up well but the tooth chatter and marks cover both surfaces and the button. It will need to be cleaned and reshaped. One of the things I appreciate about Jeff’s cleanup is that he works to protect and preserve the nomenclature on the shank of the pipes that he works on. The stamping on this one was very faint to start with so I was worried that it would disappear altogether with the cleanup. He was not only able to preserve it but it is clearer than shown in the earlier photos. I took some photos to show the clarity of the stamping. I have noticed that many restorers are not careful to protect the stamping in their cleaning process and often by the end of the restoration the nomenclature is almost destroyed. I would like to encourage all of us to be careful in our work to preserve this as it is a critical piece of pipe restoration!

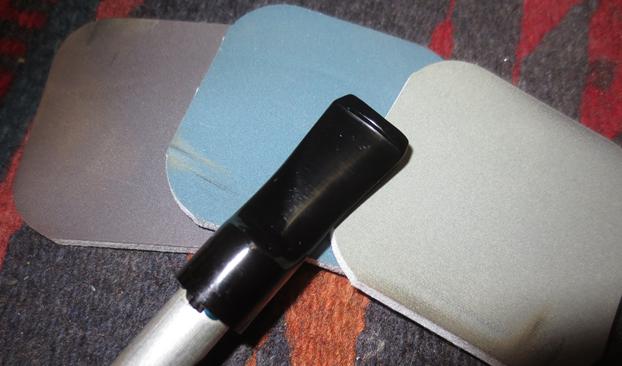

One of the things I appreciate about Jeff’s cleanup is that he works to protect and preserve the nomenclature on the shank of the pipes that he works on. The stamping on this one was very faint to start with so I was worried that it would disappear altogether with the cleanup. He was not only able to preserve it but it is clearer than shown in the earlier photos. I took some photos to show the clarity of the stamping. I have noticed that many restorers are not careful to protect the stamping in their cleaning process and often by the end of the restoration the nomenclature is almost destroyed. I would like to encourage all of us to be careful in our work to preserve this as it is a critical piece of pipe restoration! The shank encloses an aluminum tube with matching perforations to the shank. It is an integral part of the stem. Inside of the tube is a hollow balsa wood filter much like the hard maple filter found in Brigham pipes. In this case the smoke is drawn through the shank and air from outside is mixed with the smoke to either keep it warm or cool it so a clean dry smoke is enjoyed by the pipe smoker. In the earlier noted advertisement the stem and filter unit were one unit and were sold with replacements. The next photos show the pipe taken apart.

The shank encloses an aluminum tube with matching perforations to the shank. It is an integral part of the stem. Inside of the tube is a hollow balsa wood filter much like the hard maple filter found in Brigham pipes. In this case the smoke is drawn through the shank and air from outside is mixed with the smoke to either keep it warm or cool it so a clean dry smoke is enjoyed by the pipe smoker. In the earlier noted advertisement the stem and filter unit were one unit and were sold with replacements. The next photos show the pipe taken apart.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a horsehair to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips and a horsehair to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I set the bowl aside and turned my attention to the stem. I sanded the stem with 220 grit sandpaper to break up the oxidation. I started the polishing with 400 grit wet dry sandpaper to remove the scratching. It is starting to look good.

I set the bowl aside and turned my attention to the stem. I sanded the stem with 220 grit sandpaper to break up the oxidation. I started the polishing with 400 grit wet dry sandpaper to remove the scratching. It is starting to look good.  I rubbed the stem down with Denicare Mouthpiece Polish. I have a few tins of this laying around so I am trying to use them up. It does a pretty good job polishing the stem.

I rubbed the stem down with Denicare Mouthpiece Polish. I have a few tins of this laying around so I am trying to use them up. It does a pretty good job polishing the stem. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad and set the stem aside to dry after the final wipe down with oil.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad and set the stem aside to dry after the final wipe down with oil.

I put the bowl, shank and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the stem. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The wire rustication on the bowl and shank looked really good with the polished black stem. This Bing Crosby Thermostatic Filtration Lovat was another fun pipe to work on thanks to Jeff’s cleanup work. It really has an interesting and unique look that catches the eye. The combination of various brown stains really makes the pipe look attractive. It is another comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. This pipe is joining the Bing Crosby Dublin in my own collection. Thanks for reading this blog and my reflections on the pipe while I worked on it.

I put the bowl, shank and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the stem. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The wire rustication on the bowl and shank looked really good with the polished black stem. This Bing Crosby Thermostatic Filtration Lovat was another fun pipe to work on thanks to Jeff’s cleanup work. It really has an interesting and unique look that catches the eye. The combination of various brown stains really makes the pipe look attractive. It is another comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 2 inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. This pipe is joining the Bing Crosby Dublin in my own collection. Thanks for reading this blog and my reflections on the pipe while I worked on it.