Blog by Pam Otto

This week’s refurbing adventure comes courtesy of an eBay estate lot, for which the seller accepted my “Best Offer” bid. The transaction occurred on a Sunday and by Wednesday the pipes had arrived. This is the photo that accompanied the listing: All of the pipes appeared quite old, with orifice bits, and two of them really jumped out at me: a KB&B Blue Line that would need to be restemmed, but otherwise appeared to be in decent shape, and a C.P.F. Chesterfield that looked to be, and indeed is, positively enormous.

All of the pipes appeared quite old, with orifice bits, and two of them really jumped out at me: a KB&B Blue Line that would need to be restemmed, but otherwise appeared to be in decent shape, and a C.P.F. Chesterfield that looked to be, and indeed is, positively enormous.

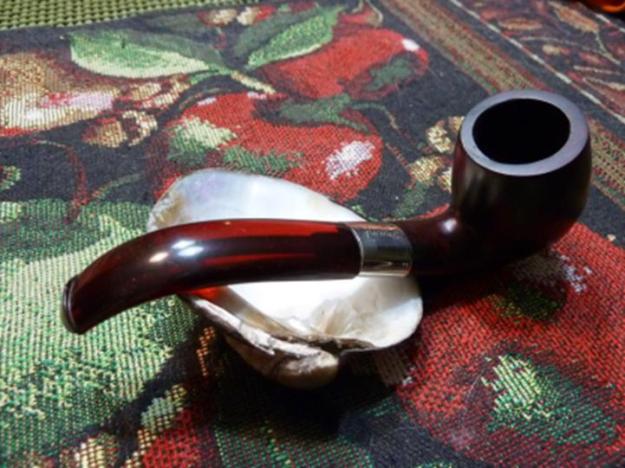

The other two pipes were older S.M. Franks. One is stamped Genuine Amber on the shank but as the stem on it is quite dark I’m going to guess it’s a replacement. The second one is stamped Frank Bakelite on the shank. It has a lovely bent red stem, way overturned, and a metal band stamped EP Silver. A few dings and a couple scratches on the bowl, and no tooth marks on the stem. I’m thinking this one, for whatever reason, was not a favorite.

Even though I’m anxious to get the Blue Line and Chesterfield cleaned up and smokable, the Frank Bakelite, with its simple needs, beckoned. It moved to the front of the queue.

I don’t know old this particular pipe is, but if it dates to the same era as the KB&B Blue Line, it could well be past the century mark. Thoughts, anyone?

At any rate, the stem of this old boy seemed like a logical place to start. I took a couple of pictures of it in its overturned state, then unscrewed it completely to see if an internal problem was to blame. Thankfully, the bone tenon was clean and solid.

Knowing I’d read how to tackle overturned stems, I looked to Steve’s blog and, sure enough, there it was in clear, easy-to-follow directions. Following the steps he listed, I filled a cup halfway with water, leaned the stem against the side of the cup and put it in the microwave. I used the highest setting and, because the cup was only half full, set the time for 1 minute—plenty of time to get the water boiling.

Knowing I’d read how to tackle overturned stems, I looked to Steve’s blog and, sure enough, there it was in clear, easy-to-follow directions. Following the steps he listed, I filled a cup halfway with water, leaned the stem against the side of the cup and put it in the microwave. I used the highest setting and, because the cup was only half full, set the time for 1 minute—plenty of time to get the water boiling.

In those 60 seconds, two things happened that I hadn’t really counted on. One, it worked (not that I had any doubts in the recommendation; it’s just that I rarely get things right the first time). And two, whether because of the vigorous bubbling of the boiling water, or because my microwave is a carousel, or even because the Bakelite was so smooth, the stem fell all the way into the water.

The material itself was fine; in fact, some of the debris from the airway got cleaned out by the bubbling water. However, the heat caused the bent stem to straighten.

Reheating the stem to restore the curve was no big deal; all I had to do next was re-bend it over a rounded object. But as I hadn’t foreseen this step, I didn’t have many options from which to choose. Paper towel tube? Nope, too flimsy. Peanut butter jar? Too big.

Then I saw it, sitting amid the excelsior of a near-empty holiday gift basket: a small summer sausage. It had a slightly narrower diameter than I’d hoped for, but it was a solid cylinder and certainly convenient. I heated the stem in boiling water again, laid it across the curve of the sausage, and applied slow, steady pressure.

The results weren’t perfect, but they could be worse. Or wurst, har har. The stem feels good in my mouth, and the curvature looks okay. However, it’s not quite as deep as it was originally, and that bothers me just a wee bit. If I can find the rolling pin I know I used to have, I may try re-curving the stem at some point in the future.

The results weren’t perfect, but they could be worse. Or wurst, har har. The stem feels good in my mouth, and the curvature looks okay. However, it’s not quite as deep as it was originally, and that bothers me just a wee bit. If I can find the rolling pin I know I used to have, I may try re-curving the stem at some point in the future.

To make the tenon fix on the stem permanent I dunked the tenon-stem assembly once again in boiling water—this time holding onto the stem so it couldn’t submerge completely. I twisted it tightly onto the pipe, counting on the slightly swelled tenon to grab hold inside the shank and the slightly softened glue in the stem to let go. I untwisted and, sure enough, the stem came off while the tenon stayed in the shank.

I dried the tenon with a soft pipe cleaner and applied super glue sparingly to the narrow threads, then twisted it back into the stem. Satisfied with the alignment, I put the pipe down to let the glue cure.

The following evening I unscrewed the stem from the bowl and the tenon withdrew from the shank just fine. I screwed it back in to make sure the repair held, then removed it once again and set it aside.

I took the bowl over to the sink and scrubbed the outside with a toothbrush dipped in Murphy’s Oil Soap. I wiped it down, then took it back to the table and rubbed it good with cotton balls soaked in 91% isopropyl alcohol.

The rim had a pretty good chip—maybe 1mm or so deep–missing at about the 8 o’clock position as you look at the bowl from the shank. While an extreme topping of the bowl would smooth things out, I felt it could also compromise the bowl’s shape. So after sizing it up from all angles, and finding that there really wouldn’t be much chance of tobacco being in contact with that area, I decided to try filling it instead.

Before proceeding with the fill, I thought it might be good to first address the inside of the bowl, which had minimal cake but a troubling bit of what looked like fuzzy mold or fungus. I didn’t want any spores getting into the fill, so I wiped everything down with 190 proof alcohol, then wrapped a piece of 220 grit sandpaper around my finger and sanded the interior thoroughly. More alcohol, then the addition of a flame. Take that, moldy fungus! After another heavy swabbing with Everclear I declared the inside done.

Before proceeding with the fill, I thought it might be good to first address the inside of the bowl, which had minimal cake but a troubling bit of what looked like fuzzy mold or fungus. I didn’t want any spores getting into the fill, so I wiped everything down with 190 proof alcohol, then wrapped a piece of 220 grit sandpaper around my finger and sanded the interior thoroughly. More alcohol, then the addition of a flame. Take that, moldy fungus! After another heavy swabbing with Everclear I declared the inside done.

Back to the rim patch… I cleaned the area to be filled with alcohol, then scrubbed it with a green Scotch Brite pad to remove any dirt and debris. I was glad I used a wide pad like that because the briar on either side of the chip was loose and came off when I scrubbed.

The fill would need to be a little wider but not any deeper—not a big deal. I packed some briar dust along the rim, then reached for the super glue to drip onto the patch.

I’ve done this many times but am still perfecting the technique. This time I learned an important lesson: Don’t attempt a maneuver like super glue-dripping, which requires a certain degree of precision, with a parrot perched on your shoulder.

(Time out for a side note: I have a large macaw named Tom who is a frequent observer of my pipe renovations. I don’t let him near smoke or fumes but other than that he’s close by pretty much all the time. He normally sits on his stand and looks down on the proceedings, but this particular night he was on my shoulder.)

Anyway, Tom shifted just as I was letting a little drip drop onto the pipe. I totally missed the briar dust and watched as the dribble made its way down the inside of the bowl. Shazbot.

I tried again, Tom shifted again, and I dripped on the outside of the bowl. Arrrr!

Fool me once, fool me twice… I wiped up the outside drip as best I could and put Tom over on his stand. I sat down and, with steadier hands, I dripped the glue a third time—on target—and after sprinkling on a little more briar dust, set the bowl aside to cure overnight. The next morning I took a flat needle file to the overfilled fill to jump start the removal of material. After that a thorough sanding with 220 grit sandpaper, first with the paper in my hand and then on my topping board, got the fill flush with the side of the bowl as well as the adjoining rim surfaces.

The next morning I took a flat needle file to the overfilled fill to jump start the removal of material. After that a thorough sanding with 220 grit sandpaper, first with the paper in my hand and then on my topping board, got the fill flush with the side of the bowl as well as the adjoining rim surfaces.

Follow-up sandings with 400 and 600 grit smoothed things out even more, but also revealed a couple of small holes in the fill. I probably had left some small air pockets in the briar dust; I couldn’t pack it down as tightly as I normally would due to its location on the rim. I refilled the fill using minute amounts of briar dust and applying the superglue with a toothpick. While these tiny patches dried, I took on the task of shining up the metal band. I wiped it down with white vinegar, then ran through the sequence of 1500-12000 micromesh pads to make it good and shiny. Using the same pads, I polished the stem as well.

While these tiny patches dried, I took on the task of shining up the metal band. I wiped it down with white vinegar, then ran through the sequence of 1500-12000 micromesh pads to make it good and shiny. Using the same pads, I polished the stem as well. To give the patches a little more time to cure, I set about cleaning out the shank. Two—count ‘em, TWO—pipe cleaners, one bristle and one regular, dipped in alcohol was all it took.

To give the patches a little more time to cure, I set about cleaning out the shank. Two—count ‘em, TWO—pipe cleaners, one bristle and one regular, dipped in alcohol was all it took.

I don’t know why the former owner didn’t smoke this pipe much, but as I set about sanding the patches I started coming up with scenarios. One, maybe it’s a crappy smoker. Only time will tell on that one. But other situations came to mind too. Maybe the stem was a problem from the get-go. Maybe it overturned after only a few smokes. Maybe the bend didn’t feel right. (Not that that will be problem any more. Ha.) Maybe it gurgled.

Whatever the reason for its nearly new condition, the pipe was rapidly coming back together again. Even with a 20 minute detour to sand off my super glue mistake inside of the bowl, the end was in sight.

I sanded the outside of the bowl and shank with 400 and 600 grit paper and followed up with the 1500 micromesh pad to take care of some slight scratches and dings. Next I got out the aniline stains to even up the color of the briar. Although much of the bowl was still quite dark, it was lighter on either side of the rim patch. I wiped on some oxblood stain, flamed it, wiped on dark brown and flamed again. A little bit of dabbing here and there with the dark brown and the staining was complete.

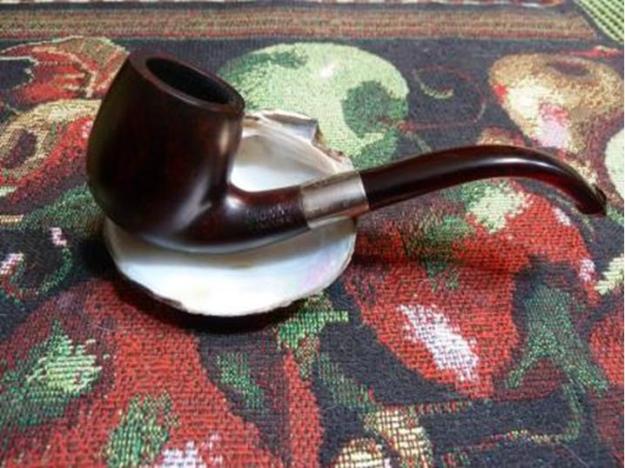

I slipped the metal band on the shank, screwed on the stem, smiled when it stopped right where it should, and headed over to the buffer.

(New development here at Casa Otto: Aided by a couple of gift cards from my brother, I invested in a Foredom M.BL—a small bench lathe with a variable speed motor that tops out at 7,000 rpm. I haven’t gone over what I estimate is about 1,200 rpm, based on the intervals marked on the speed control, and the results have been outstanding. Not only is it a fabulous machine, but it’s also small and fits nicely on the kitchen counter. It’s a huge improvement over my jerry-rigged drill press buffing station in the garage, and on a day like today when the outside temp is 2°F, a heck of a lot warmer too. Next step: Setting up the buffer in a spare bedroom. Upside to this will be getting counter space back. Downside is that the spare room is quite a distance from where the beer and snacks that fuel all good pipe projects are stored.)

I first buffed the assembled pipe with White Diamond, wiped it down with a flannel rag, then gave it three coats of carnauba, buffing with a clean wheel after each application.

This old pipe didn’t see much action during its go-around. But today, chip-free, moldy fungus-free and with a stem that sits where it should, it stands ready for a new century of service.