by Steve Laug

This afternoon I decided to work on the pipe that Jeff picked up on Facebook Marketplace from a seller in Seattle, Washington, USA on 02/26/2025. It is a beautifully grained larger Freehand with a Plateau rim and shank end. It has a fancy amber coloured acrylic saddle stem. It is a beautiful grained piece of briar that I can appreciate why he chose it. The pipe is stamped on the underside of the shank and reads Wiley 87 [over] ‘Unique’ [over] Patina [over] U.S.A. [over] 11. The briar is dirty from use with a moderate cake in the bowl and a light overflow of lava on the rim top filling in the inner edge and some of the plateau around the edge. The plateau shank end was dusty and dirty. The stem fit well against the shank end. The amber coloured acrylic saddle stem had some light tooth chatter and scratches on the top and underside of the stem ahead of the button. There was no logo on the stem. Jeff took photos of the pipe before he started his clean up work on it. I have included them below.

Jeff took some close up photos of the bowl and rim top. You can see the light lava coat in the plateau top. The inner edge of the rim looks good with a spot of darkening and damage on the left back side. There is a light cake in the bowl that seems to have been recently reamed. The photos of the stem show the scratching and tooth marks in the stem at the button.

Jeff took some close up photos of the bowl and rim top. You can see the light lava coat in the plateau top. The inner edge of the rim looks good with a spot of darkening and damage on the left back side. There is a light cake in the bowl that seems to have been recently reamed. The photos of the stem show the scratching and tooth marks in the stem at the button.

Jeff took photos of the sides and heel of the bowl to give a sense of the beautiful grain on this piece briar. It is a really stunning pipe.

Jeff took photos of the sides and heel of the bowl to give a sense of the beautiful grain on this piece briar. It is a really stunning pipe.

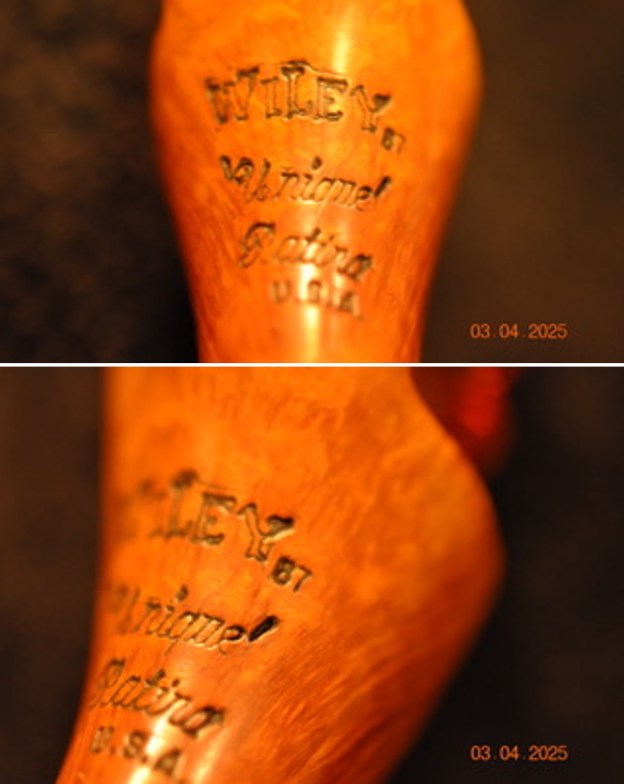

Jeff took photos to capture the stamping on the underside of the shank. It is clear and readable as noted above. I am guessing that the pipe was made in 1987 from the stamp next to Wiley. The 11 after the USA is probably a grade stamp.

Jeff took photos to capture the stamping on the underside of the shank. It is clear and readable as noted above. I am guessing that the pipe was made in 1987 from the stamp next to Wiley. The 11 after the USA is probably a grade stamp. I looked on my usual sites for information on the brand. I turned first to Pipephil’s site and did not find a listing for the brand. That is unusual. I then turned to Pipedia to see what was available there (https://pipedia.org/wiki/Wiley). I quote from that article below:

I looked on my usual sites for information on the brand. I turned first to Pipephil’s site and did not find a listing for the brand. That is unusual. I then turned to Pipedia to see what was available there (https://pipedia.org/wiki/Wiley). I quote from that article below:

Having been apprenticed in wood carving, Randy Wiley fell into pipe making in the 1970s as a means to follow to his passion. At the age of 25, and after two years with a Florida based pipe manufacturer, Wiley struck out on his own and has since become one of the most recognizable craftsmen in American pipe making.

Having been apprenticed in wood carving, Randy Wiley fell into pipe making in the 1970s as a means to follow to his passion. At the age of 25, and after two years with a Florida based pipe manufacturer, Wiley struck out on his own and has since become one of the most recognizable craftsmen in American pipe making.

Randy Wiley is a distinctive maker as he never sandblasts his work and remains one of the few makers that will oil-cure a pipe. He currently produces around 1000 pipes annually, and the majority are smooth or completely rusticated. Sometimes he will carve a feather over a sandpit, which allows the beautiful grain to not be covered in texture. Aside from his shallow rusticated pieces (done with a rotary tool), Randy also makes some craggy carved pieces for his Old Oak line. All of his stems are made from acrylic, and many of them are very colorful, and twisted by design. Courtesy, Smokingpipes.com

Jeff cleaned up the pipe for me. He reamed the bowl with a PipNet pipe reamer and cleaned it up with a Savinelli Fitsall Pipe Knife. He scrubbed the exterior with Murphy’s Oil Soap and a tooth brush to clean off the grime off the finish and overflow of lava on the rim top. He cleaned up the internals of the shank, mortise and stem with pipe cleaners, cotton swabs, shank brushes and alcohol to remove all of the oils and tars in the pipe. He soaked the stem in Briarville’s Stem Deoxidizer, rinsed it with warm water and looked amazingly clean. When it arrived here in Vancouver it was a clean pipe and I knew what I had to work with. I took photos of it before I started my part of the restoration.

I took photos of the rim top and the stem to show their condition once it arrived in Canada. Jeff was able to clean up the thick cake and lava overflow that was shown in the rim and bowl photos above. The plateau outer edge and the beveled inner edge of the rim look quite good. The plateau shank end also cleaned up well. He was also able to get rid of the grime and grit in the surface of the briar. There was still some darkening on the rim bevel that I would need to remove. The stem looked very clean and with polishing would shine. The amber acrylic worked well with the bowl. There were light tooth marks and chatter on both sides near the button.

I took photos of the rim top and the stem to show their condition once it arrived in Canada. Jeff was able to clean up the thick cake and lava overflow that was shown in the rim and bowl photos above. The plateau outer edge and the beveled inner edge of the rim look quite good. The plateau shank end also cleaned up well. He was also able to get rid of the grime and grit in the surface of the briar. There was still some darkening on the rim bevel that I would need to remove. The stem looked very clean and with polishing would shine. The amber acrylic worked well with the bowl. There were light tooth marks and chatter on both sides near the button. I have noticed on some repairs that folks don’t pay much attention to the stamping when they are restoring a pipe. To me this is a critical part of the restoration – to leave it undamaged. It is the only link we have to who made the pipe. I took a photo of the stamping on the underside of the shank to show that it was readable and undamaged by the cleanup work. I removed the stem from the shank and took a photo of the parts to give a sense of what the pipe looks like.

I have noticed on some repairs that folks don’t pay much attention to the stamping when they are restoring a pipe. To me this is a critical part of the restoration – to leave it undamaged. It is the only link we have to who made the pipe. I took a photo of the stamping on the underside of the shank to show that it was readable and undamaged by the cleanup work. I removed the stem from the shank and took a photo of the parts to give a sense of what the pipe looks like. I started polishing the briar and the inner edge of the bowl with micromesh sanding pads. I wet sanded it with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth. The bowl began to take on a rich shine and grain was beginning to stand out. I wet sanded with all of the pads and wiped the bowl down after each pad with a soft cloth.

I started polishing the briar and the inner edge of the bowl with micromesh sanding pads. I wet sanded it with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth. The bowl began to take on a rich shine and grain was beginning to stand out. I wet sanded with all of the pads and wiped the bowl down after each pad with a soft cloth.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I used a horsehair shoe brush to work it into the plateau top. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I rubbed the bowl and shank down with Before & After Restoration Balm to deep clean the finish on the bowl and shank. The product works to clean, enliven and protect the briar. I worked it in with my fingers to get it into the briar. I used a horsehair shoe brush to work it into the plateau top. I let it sit for 10 minutes then I wiped it off and buffed it with a soft cloth. The briar really began to have a rich shine. I took some photos of the bowl at this point to mark the progress in the restoration. It is a beautiful bowl.

I set the bowl aside and worked on the stem at this point in the process. I sanded the stem surface with 220 grit sandpaper to remove the marks chatter on the stem surface.

I set the bowl aside and worked on the stem at this point in the process. I sanded the stem surface with 220 grit sandpaper to remove the marks chatter on the stem surface.  I further sanded it with 320-3500 grit 2×2 inch sanding pads and smoothed out the sanding marks further. I wiped it down after each sanding pad with an Obsidian Oil cloth to remove the sanding debris. It was looking very good by the last pad.

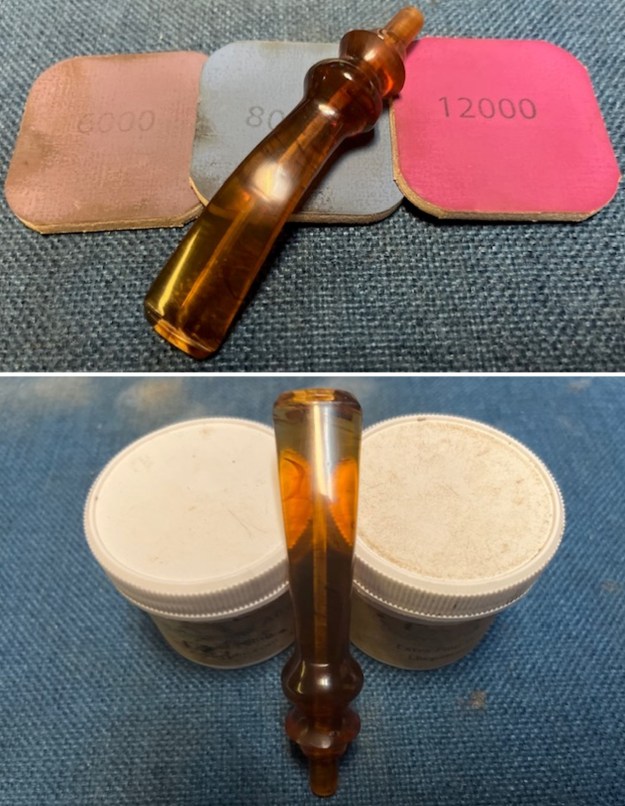

I further sanded it with 320-3500 grit 2×2 inch sanding pads and smoothed out the sanding marks further. I wiped it down after each sanding pad with an Obsidian Oil cloth to remove the sanding debris. It was looking very good by the last pad. I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a damp cloth to remove the sanding dust. I finished by wiping the stem down with a final coat of Obsidian Oil and set it aside to dry.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a damp cloth to remove the sanding dust. I finished by wiping the stem down with a final coat of Obsidian Oil and set it aside to dry.

I put the stem back on the Randy Wiley 87 Unique Patina 11 Freehand pipe and took the pipe to the buffer. I buffed the bowl and stem with Blue Diamond to polish the briar and the acrylic. Blue Diamond does a great job on the smaller scratches that remain in both. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up really nicely with a great contrasting stain look to the briar. The finished pipe is shown in the photos below. This is a beautiful Randy Wiley 87 Unique Patina Freehand – the fancy turned acrylic stem and plateau rim top and smooth shank end give the pipe a great look. The polished amber acrylic stem looks really good with the rich browns standing out in the grain. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 ½ inches, Outside diameter of the bowl: 2 inches, Chamber diameter: 1 inch. The weight of the pipe is 2.57 ounces/73 grams. This is another pipe that I will be putting on the rebornpipes online store in the American Pipe Makers and Pipemaking Companies Section shortly, if you are interested in adding it to your collection. Thanks for walking through the restoration with me on this beauty!

I put the stem back on the Randy Wiley 87 Unique Patina 11 Freehand pipe and took the pipe to the buffer. I buffed the bowl and stem with Blue Diamond to polish the briar and the acrylic. Blue Diamond does a great job on the smaller scratches that remain in both. I gave the bowl and the stem several coats of carnauba wax and buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up really nicely with a great contrasting stain look to the briar. The finished pipe is shown in the photos below. This is a beautiful Randy Wiley 87 Unique Patina Freehand – the fancy turned acrylic stem and plateau rim top and smooth shank end give the pipe a great look. The polished amber acrylic stem looks really good with the rich browns standing out in the grain. The dimensions of the pipe are Length: 6 ½ inches, Height: 2 ½ inches, Outside diameter of the bowl: 2 inches, Chamber diameter: 1 inch. The weight of the pipe is 2.57 ounces/73 grams. This is another pipe that I will be putting on the rebornpipes online store in the American Pipe Makers and Pipemaking Companies Section shortly, if you are interested in adding it to your collection. Thanks for walking through the restoration with me on this beauty!

As always, I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipe men and women who hold our pipes in trust until they pass on into the trust of those who follow us.