by Steve Laug

I finished repairing and restoring the four pipes that Michael sent to me for work on impending burnout and damage to the bowl walls on all four. I sent them back to him and gave him a call to let him know they were on their way back to him. On January 13 I received an email from Michael about another pipe that he sent to me. I have included the email below.

Hi Steve! I mailed a pipe to you today; the tracking (Customs)# is LH264469865US. I enclosed a note with it which mentions that I collect Willmer pipes and this one came to me with a sizable burnout. Willmers are somewhat difficult to find; I’ve got 16 of them and I probably won’t be getting any more. Their “high grades” were always smooth and a bit on the large size. This one is stamped “Hand Made”, which was the lowest of their high grade line. But- all Willmers were made of super good quality briar and are excellent smokers. Even though this one has a number of fills to cover up small, cosmetic deficiencies in the grain, it’s a great pipe and in this day and age it’s a fairly rare Willmer to find. When you look at it please let me know if you can fix it or not. Thank you! — As ever, Michael

Yesterday, January 26, 2926 I received a package from Michael. I opened it to examine a beautifully grained Willmer. It is a Willmer Hand Made Egg with two fluted valleys on the front of the bowl. It has an acrylic saddle stem. It is in good condition as can be seen in the photos below. It is stamped on the left side of the shank and reads Willmer [over] Hand Made. On the right side it is stamped Made in England. The stamping is clear and readable. The pipe has rich finish with a blend of brown stains on a richly grained smooth finish that the shape follows well. The finish was quite clean and shiny. The bowl had a moderate cake and there appeared to be some damaged areas midbowl on the back, left side and the front. The rim top had some lava coat on the rim top and inner edge. The original saddle stem with the Willmer, “W” logo on the left side has some light tooth marks and chatter on both sides. I took photos of the pipe to show what it looked like before I started working on it.

I took photos of the bowl and rim top to show the thickness of the cake and the lava coat on the rim top. The inner edge of the bowl has some lava and potential damage under the coat. It is hard to know until I clean it up. You can see the fluted troughs on the front of the bowl. The stem photos show the condition of the saddle stem ahead of the button.

I took photos of the bowl and rim top to show the thickness of the cake and the lava coat on the rim top. The inner edge of the bowl has some lava and potential damage under the coat. It is hard to know until I clean it up. You can see the fluted troughs on the front of the bowl. The stem photos show the condition of the saddle stem ahead of the button. The stamping on the sides of the shank are clear and readable as noted above. I took a photo of the pipe with the stem removed to give a sense of the proportions of the pipe. Under the grime it is a real beauty.

The stamping on the sides of the shank are clear and readable as noted above. I took a photo of the pipe with the stem removed to give a sense of the proportions of the pipe. Under the grime it is a real beauty.

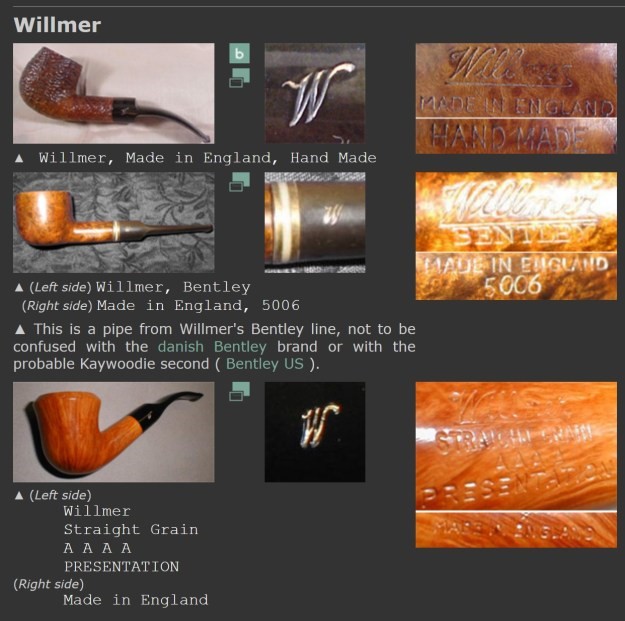

I turned to Pipephil to get a quick review of the Willmer Company before I started my work on this pipe (http://www.pipephil.eu/logos/en/logo-w3.html). I quote the side bar from the site below.

I turned to Pipephil to get a quick review of the Willmer Company before I started my work on this pipe (http://www.pipephil.eu/logos/en/logo-w3.html). I quote the side bar from the site below.

Willmer is a brand of H. Willmer & Son Ltd. The factory closed down about 2006-07 after more then 60 years activity and two generations of makers. Gradings until the 1980s (ascending): BA, A, AA, and AAA. After this date Willmer introduced the AAAA and AAAA PRESENTATION as top grades.  The pipe I was working on no letter stamping on it which has stamping similar to the photo in the top photo.

The pipe I was working on no letter stamping on it which has stamping similar to the photo in the top photo.

I turned to Pipedia to get more information on the brand (https://pipedia.org/wiki/Willmer). The first paragraph dispelled of the belief that Willmer had been a carver for Charatan in his own words. I quote a portion of the article to give a sense of the history of the brand.

Willmer was founded in London. According to the website, which doesn’t exist anymore because the Willmer factory has been closed in 2006/07, the firm was in business “for more than 60 years” by 2003. Willmer was homed then in Southend-on-Sea, Essex, so not far from the Cadogan plant.

When Willmer first started, they definitely strived to compete with brands in the high-end market. Due to the excellent quality of the pipes Willmer was frequently asked to produce private label pipes for England’s best renowned pipe retailers. So many pipes are not easily recognized as Willmers for stamped under the name of the respective shop. Willmer’s own pipes were stamped “Willmer – Made in England” and showed a sweeping “W” in white or gold on top or left side of the stem. The earlier grading had AAA as top grade followed by AA, A, AB etc.

Sometime in the 1980’s, Willmer went through some major changes. The move to Essex was already mentioned above. They continued making highly respectable freehands – often copying some of the stunning Charatan shapes of days gone by. The grading was altered. What used to be an AAA now became the additional name “Presentation” and was stamped with AAAA. Funny enough, the fourth A was often larger than the three before. The other grades were changed accordingly.

Now I knew that I was working on a Willmer Hand Made Egg with an acrylic Saddle Stem.

I turned to work on the pipe itself. I reamed the bowl with a PipNet pipe reamer using the cutting heads 2 and 3. I finished the reaming with a Savinelli Fitsall Pipe Knife. I sanded the walls of the bowl with 220 grit sandpaper wrapped around a piece of dowel.

I cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and both bristle and regular pipe cleaners.

I cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and both bristle and regular pipe cleaners.  I scrubbed the bowl and shank with a tooth brush and some undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the dust and soap from the finish. I dried it off with a soft cloth and it looked much better.

I scrubbed the bowl and shank with a tooth brush and some undiluted Murphy’s Oil Soap. I rinsed it off with warm water to remove the dust and soap from the finish. I dried it off with a soft cloth and it looked much better.

I sanded the exterior of the bowl with 320-3500 grit 2×2 inch sanding pads to remove the scratching in the finish. I wiped the bowl down with a damp cloth after each sanding pad. It really began to look much better.

I sanded the exterior of the bowl with 320-3500 grit 2×2 inch sanding pads to remove the scratching in the finish. I wiped the bowl down with a damp cloth after each sanding pad. It really began to look much better.

I polished the briar with 1500-12000 grit micromesh sanding pads to develop the shine. It began to look very good. It had a rich shine in the finish.

I polished the briar with 1500-12000 grit micromesh sanding pads to develop the shine. It began to look very good. It had a rich shine in the finish.

To address the checking and the divot on the inner wall around the middle of the bowl. I wiped it clean with a cotton pad and alcohol to remove any debris on the surface. I mixed a batch of JB Weld to repair the divot and checking on the bowl walls. I pressed it into the damaged areas with a dental spatula. I set the bowl aside for the repair to cure.

To address the checking and the divot on the inner wall around the middle of the bowl. I wiped it clean with a cotton pad and alcohol to remove any debris on the surface. I mixed a batch of JB Weld to repair the divot and checking on the bowl walls. I pressed it into the damaged areas with a dental spatula. I set the bowl aside for the repair to cure.

Once it cured I sanded it smooth with a piece of 220 grit sandpaper wrapped around a piece of dowel to smooth out the repair. I wiped it down with a damp pad to remove the sanding debris.

Once it cured I sanded it smooth with a piece of 220 grit sandpaper wrapped around a piece of dowel to smooth out the repair. I wiped it down with a damp pad to remove the sanding debris.

I mixed a batch of bowl coating composed of sour cream and activated charcoal powder to give the bowl a thin coat of the mixture. I used a folded pipe cleaner to paint the walls and heel of the bowl with the mixture. I set it aside to cure.

I mixed a batch of bowl coating composed of sour cream and activated charcoal powder to give the bowl a thin coat of the mixture. I used a folded pipe cleaner to paint the walls and heel of the bowl with the mixture. I set it aside to cure.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips to work it into the finish. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips to work it into the finish. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes then I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

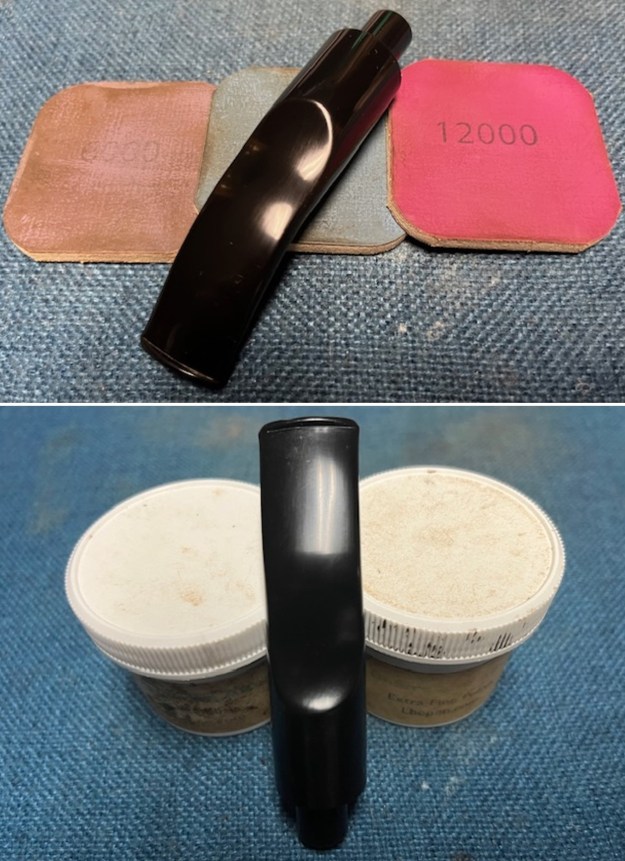

I sanded the tooth marks and chatter on the top and underside of the stem with a folded piece of 220 grit sandpaper.

I sanded the tooth marks and chatter on the top and underside of the stem with a folded piece of 220 grit sandpaper.  I continued sanding it with 320-3500 grit 2×2 inch pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad.

I continued sanding it with 320-3500 grit 2×2 inch pads. I wiped the stem down with an Obsidian Oil cloth after each sanding pad. I polished the acrylic with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the acrylic with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This is a unique Willmer Hand Made Egg with a saddle stem I have worked. It is a beauty. I put the bowl and stem back together again and buffed the bowl and the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem several coats of carnauba wax. I carefully buffed the entire pipe with a clean buffing pad to raise the shine. I finished buffing with a microfiber cloth to deepen the shine. The finished pipe looks very good. The grain is quite beautiful a mix of straight and flame around the bowl sides and birdseye on the rim top and heel. The pipe feels great in the hand. The two fluted valleys on the front of the bowl makes this interesting shape fit well in either the right or left hand. The finished Willmer Hand Made Egg is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.20 ounces/35grams. This great looking Briar turned out very well. It should be a great pipe Thanks for walking through the restoration with me as I worked this beautiful Willmer Egg. This one will soon be heading back to Michael. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This is a unique Willmer Hand Made Egg with a saddle stem I have worked. It is a beauty. I put the bowl and stem back together again and buffed the bowl and the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem several coats of carnauba wax. I carefully buffed the entire pipe with a clean buffing pad to raise the shine. I finished buffing with a microfiber cloth to deepen the shine. The finished pipe looks very good. The grain is quite beautiful a mix of straight and flame around the bowl sides and birdseye on the rim top and heel. The pipe feels great in the hand. The two fluted valleys on the front of the bowl makes this interesting shape fit well in either the right or left hand. The finished Willmer Hand Made Egg is shown in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.20 ounces/35grams. This great looking Briar turned out very well. It should be a great pipe Thanks for walking through the restoration with me as I worked this beautiful Willmer Egg. This one will soon be heading back to Michael. Thanks for reading this blog and my reflections on the pipe while I worked on it.