by Steve Laug

The next pipe on the table came to us from one of our pipe hunts or a trade but neither Jeff or I remember when and where we picked it up. It is a classically smooth Peterson’s Dublin 207 Pot. The finish is quite nice with at that classic Peterson’s smooth finish. The pipe pretty clean with the exterior polished and dust free. The bowl had been reamed somewhere along the way and then lightly smoked long enough to have a thin cake develop. The rim top was in good condition and the inner edge looked quite good. The pipe is stamped on the left side of the shank and reads K & P [over] Dublin. The right side had a circular Made in Ireland followed by the shape number 207. On the oxidized Sterling Silver band, it is stamped K&P in shields [over] Sterling Silver. The stamping is clear and readable on both the pipe and band. The fishtail stem is clean – no tooth marks and chatter. It looks like there is a spot of repair on the underside of the stem against the button. I took photos of the pipe before I starting work on it.

I took photos of the rim top to show the lack of cake in the clean bowl and rim top and edges. The stem was also in decent condition other than scratches and nick marks.

I took photos of the rim top to show the lack of cake in the clean bowl and rim top and edges. The stem was also in decent condition other than scratches and nick marks. The stamping on the sides of the shank read as noted above. The photo shows that they are faint but clear and readable. The stamping on the silver is also readable though heavily oxidized. I took a photo of the pipe with the stem removed to show the overall look of stem, tenon and profile of the pipe. It is a great looking pipe.

The stamping on the sides of the shank read as noted above. The photo shows that they are faint but clear and readable. The stamping on the silver is also readable though heavily oxidized. I took a photo of the pipe with the stem removed to show the overall look of stem, tenon and profile of the pipe. It is a great looking pipe.

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I am including the link to the Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I turned to “The Peterson Pipe” by Mark Irwin and Gary Malmberg to get some background on the Peterson’s London Made England line. On page 298 it had the following information.

“Dublin” (1906-2003) Although DUBLIN appears under PETERSON’s on many pipes over the decades, it has served mostly to part of the brand name. The word first appeared on pipes hallmarked 1906-11, stamped PETERSON’S over PATENT over DUBLIN. The simpler PETERSON’S over DUBLIN first appeared on pipes hallmarked 1912 after the expiration of the patent. Illustrations of pipes in the’37 catalog show a random dispersion of the stamp PETERSON’S over OF DUBLIN together with the ordinary PETERSON’S over DUBLIN on ever model offered. Specimens of the former will bear either an Irish COM and almost certainly date from 1945-62. It was first mentioned in print as pat of the model name in the’68 price list, as K&P DUBLIN, in ’92 for a Danish market line.

I knew the date for the pipe I was working on from the stamping on the silver– 1978. Since the one I was working on did not have a D shape it is not provable that it was made for the Danish market. Now it was time to work on the pipe.

I scrubbed the briar with a tooth brush and undiluted Murphy’s Oil Soap. I worked over the grime on the bowl and shank as well as the debris inside the bowl and then rinsed the pipe with warm running water. I dried it off with a clean soft towel.

I polished the Sterling Silver band on the shank with a silver polish on cotton pads to remove the tarnish and polish it.

I polished the Sterling Silver band on the shank with a silver polish on cotton pads to remove the tarnish and polish it.

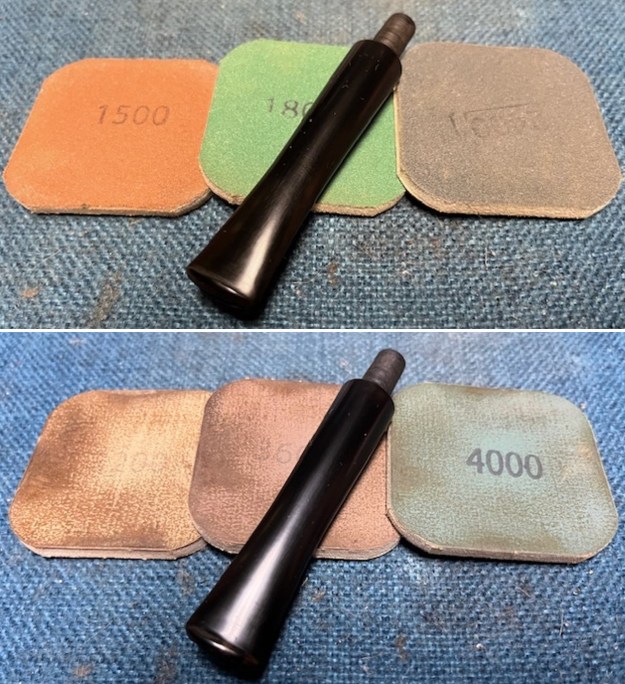

I polished the briar with 1500-12000 grit micromesh pads – dry sanding it with each pad and wiped down the bowl after each pad. I gave it a final wiped with a Briar Wipe cloth to polish the finish.

I polished the briar with 1500-12000 grit micromesh pads – dry sanding it with each pad and wiped down the bowl after each pad. I gave it a final wiped with a Briar Wipe cloth to polish the finish.

The bowl was clean the briar looked very good, so I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes while I worked on the stem. After the time passed I buffed it with a cotton cloth to deepen the shine. The grain came alive with the balm.

The bowl was clean the briar looked very good, so I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes while I worked on the stem. After the time passed I buffed it with a cotton cloth to deepen the shine. The grain came alive with the balm.

I sanded out the scratches in the stem at the shank end. There marks, almost small cuts in the vulcanite that I sanded out with 320-3500 grit 2×2 inch pads. I was able to remove the marks and give the stem a rich shine. There was some glue from a previous repair on the tenon and face of the stem to expand the tenon. I scraped off the excess glue and sanded the tenon and the stem surface at the same time.

I sanded out the scratches in the stem at the shank end. There marks, almost small cuts in the vulcanite that I sanded out with 320-3500 grit 2×2 inch pads. I was able to remove the marks and give the stem a rich shine. There was some glue from a previous repair on the tenon and face of the stem to expand the tenon. I scraped off the excess glue and sanded the tenon and the stem surface at the same time. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This K & P Dublin 207 Smooth Pot is a nice-looking pipe. The grain around the bowl sides and shank really stand out with the polishing. The finish on the pipe is in excellent condition and the contrasting stains work well to give some depth to the grain. The polished silver band and the black vulcanite, fish tail taper stem add to the mix. The pipe is really quite eye-catching. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel, carefully avoiding the stamping on the shank. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished K & P Dublin 207 Pot is quite nice and feels great in the hand. The dimensions of the pipe are Length: 5 ¾ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 45 grams/1.59 ounces. Thanks for walking through the restoration with me as I worked over another interesting pipe. I will be adding it to the Irish Pipe Makers Section of the rebornpipes store soon. If you want to add it to your collection send me an email or a message! Thanks for your time.

This K & P Dublin 207 Smooth Pot is a nice-looking pipe. The grain around the bowl sides and shank really stand out with the polishing. The finish on the pipe is in excellent condition and the contrasting stains work well to give some depth to the grain. The polished silver band and the black vulcanite, fish tail taper stem add to the mix. The pipe is really quite eye-catching. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel, carefully avoiding the stamping on the shank. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished K & P Dublin 207 Pot is quite nice and feels great in the hand. The dimensions of the pipe are Length: 5 ¾ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 45 grams/1.59 ounces. Thanks for walking through the restoration with me as I worked over another interesting pipe. I will be adding it to the Irish Pipe Makers Section of the rebornpipes store soon. If you want to add it to your collection send me an email or a message! Thanks for your time.