by Steve Laug

The next pipe I have chosen is a bit of a mystery pipe with stamping that is not clear as much of it is covered by a K&P nickel band on the shank. This one is a nice smaller size pipe with a pencil shank and a Peterson’s P-lip stem. It reminds me of a Captain Pete N24 Rhodesian that I restored a while ago (https://rebornpipes.com/2023/11/28/fresh-life-for-a-captain-peterson-made-in-england-n24-rhodesian/). It looks a lot like that one! It came to us from a pipeman in Naples, Florida, USA on 07/17/2024 as a donation. This pipe had been well smoked and there was a cake in the bowl and lava overflowing on the inner edge and the rim top. The briar was dirty with grime and oils ground into the finish and some of the lava flowing down the bowl sides. The nickel ferrule was oxidized but undamaged. It was stamped with the K&P stamp [over] a refined shamrock, a reclining wolfhound and a tower without a door. The pipe itself was stamped on the left side and though partially covered with the nickel band read Lumber [followed by] what could be Executive [over] Clifton [followed by] what looked like Make. On the right side it had the shape number 125. The ferrule was stamped K& P over Peterson’s on the left side. The stem was oxidized and had light tooth marks and chatter on both sides ahead of the button. Jeff took photos of the pipe before he started his clean up work on it.

Jeff captured the cake in the bowl and the light lava overflow onto the rim top and inner edge of the bowl in his photos. The stem surface had light tooth chatter and marks and was oxidized.

Jeff captured the cake in the bowl and the light lava overflow onto the rim top and inner edge of the bowl in his photos. The stem surface had light tooth chatter and marks and was oxidized.

He took photos of the sides and the heel of the bowl to show the interesting grain patterns in the briar. It was quite beautiful.

He took photos of the sides and the heel of the bowl to show the interesting grain patterns in the briar. It was quite beautiful.

He also took some photos of the shank sides to capture the stamping on the shank and the nickel band. The stamping on the shank were clear but covered by the band. The band bore the K&P stamp.

He also took some photos of the shank sides to capture the stamping on the shank and the nickel band. The stamping on the shank were clear but covered by the band. The band bore the K&P stamp.

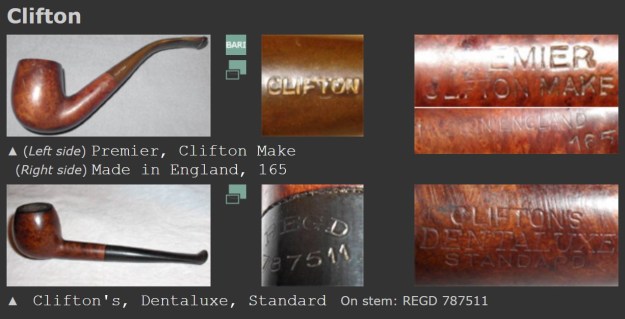

The mystery was in front of me… what was the stamping on the pipe? I could discern Lumber followed by what could be Executive but the second word was not clear as it was under the nickel band. The word underneath was Clifton followed by what looked like the word Make. I did some searching on Pipephil’s site (http://www.pipephil.eu/logos/en/logo-c5.html) and found a listing for Clifton pipes. I have included a screen capture of the section. I have also included the sidebar information.

The mystery was in front of me… what was the stamping on the pipe? I could discern Lumber followed by what could be Executive but the second word was not clear as it was under the nickel band. The word underneath was Clifton followed by what looked like the word Make. I did some searching on Pipephil’s site (http://www.pipephil.eu/logos/en/logo-c5.html) and found a listing for Clifton pipes. I have included a screen capture of the section. I have also included the sidebar information. Brand of Hall & Fitzgerald (J.M. Lopes, p. 86, op. cit.)

Brand of Hall & Fitzgerald (J.M. Lopes, p. 86, op. cit.)

From the side bar I learned of the connection to Hall & Fitzgerald. I did a Google search on Hall & Fitzgerald. I came across a link on vkpipes to a pipe made by them. It is interesting to note that they had quite a few brands in their stable (https://vkpipes.com/pipeline/hall-fitzgerald-straight-grain/). The Clifton line is listed in the quote below.

Hall & Fitzgerald is first mentioned in an 1878 Directory of Bristol as a ‘Fancy Goods Warehouse’. Within a few years the company is in the partnership of William Sydney Hall and Edward Thurston Davies trading as Hall & Fitzgerald, of 147 Temple Street, Bristol, Tobacconists and Fancy Goods Merchants. Silver hallmarks for pipe fittings are registered in London in 1899 and in Chester in 1901. Hall & Fitzgerald is making and selling smoking pipes until liquidation and closing in 1982 (except the World War II years). Known brands: Clifton, Dorchester, Excelsior, Hercules, Oxford, Craftsman and Wessex.

With that information at hand I turned to work on the pipe itself. Jeff had thoroughly cleaned up the pipe. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the stem with Soft Scrub to remove as much of the oxidation as possible. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and rinsed it off with warm water. I took photos of the pipe once I received it.

I took photos of the rim top and bowl as well as the stem to give a sense of the condition of both. The rim top looked had some scratching on the top and some damage to the inner edge but over all it was in much better condition than I thought. The stem cleaned up well and the tooth marks on the top and underside ahead of the button are visible in the photos.

I took photos of the rim top and bowl as well as the stem to give a sense of the condition of both. The rim top looked had some scratching on the top and some damage to the inner edge but over all it was in much better condition than I thought. The stem cleaned up well and the tooth marks on the top and underside ahead of the button are visible in the photos. I took photos of the stamping on the shank sides. The are faint and readable as noted above. The band covers part of the stamping on the left side. I took a photo of the stamping on the top of the nickel band. It was clear and readable. I took the stem out of the shank and took a photo of the overall look of the pipe.

I took photos of the stamping on the shank sides. The are faint and readable as noted above. The band covers part of the stamping on the left side. I took a photo of the stamping on the top of the nickel band. It was clear and readable. I took the stem out of the shank and took a photo of the overall look of the pipe.

I decided to start my work on the pipe by addressing the damage on the inside edge of the bowl and the rim top. I used a folded piece of 220 grit sandpaper to smooth out the edge. I wiped it down with a damp cloth and the rim top damage and darkening on the inner and outer edges were gone.

I decided to start my work on the pipe by addressing the damage on the inside edge of the bowl and the rim top. I used a folded piece of 220 grit sandpaper to smooth out the edge. I wiped it down with a damp cloth and the rim top damage and darkening on the inner and outer edges were gone. I sanded the briar with 320-3500 grit 2×2 inch sanding pads. I wiped the bowl down after each sanding pad to remove the sanding debris. It really looks much better.

I sanded the briar with 320-3500 grit 2×2 inch sanding pads. I wiped the bowl down after each sanding pad to remove the sanding debris. It really looks much better.

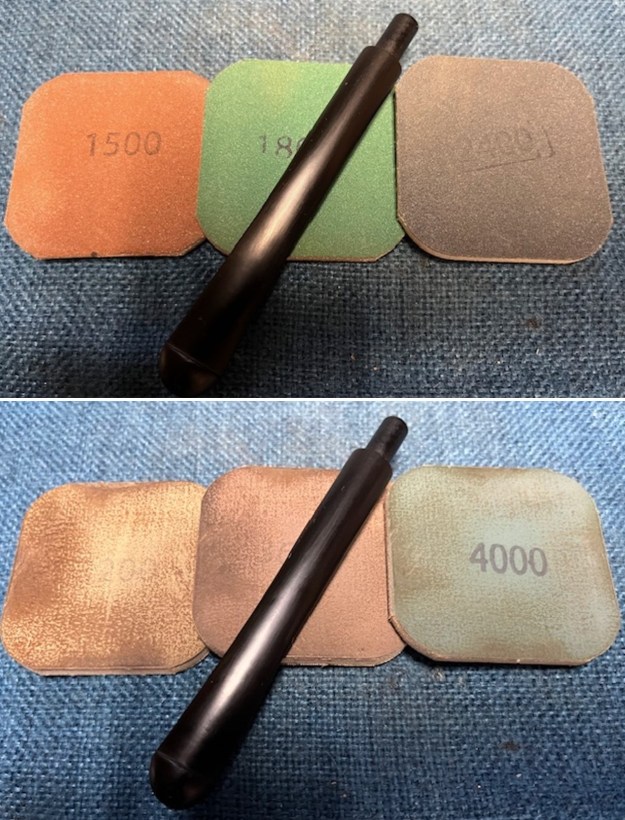

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

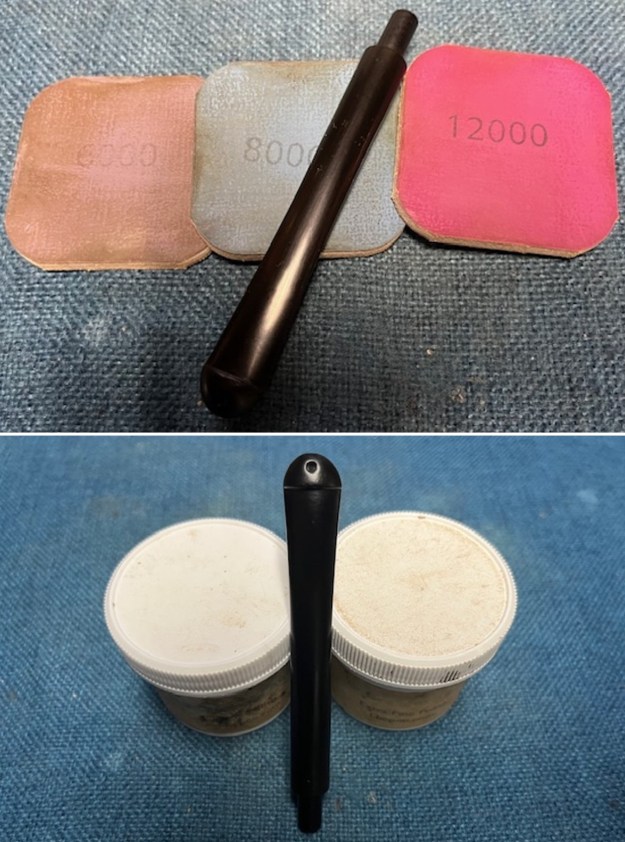

I set the bowl aside and turned to work on the stem. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I set the bowl aside and turned to work on the stem. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Clifton Make Lumber Exec… 125 Pencil Shank Rhodesian with a vulcanite taper stem is a great looking pipe now that it has been restored. The beautiful grain that shines through the polished finish is stunning. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Clifton Make 125 Rhodesian fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 22 grams/.74 ounces. I will be putting the pipe on the rebornpipes store in the British Pipe Makers Section. If you are interested in this pipe send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Clifton Make Lumber Exec… 125 Pencil Shank Rhodesian with a vulcanite taper stem is a great looking pipe now that it has been restored. The beautiful grain that shines through the polished finish is stunning. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Clifton Make 125 Rhodesian fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 inches, Height: 1 ¼ inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 22 grams/.74 ounces. I will be putting the pipe on the rebornpipes store in the British Pipe Makers Section. If you are interested in this pipe send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!