by Steve Laug

In November I received an email from Mario about working on some of his Dad’s pipes. Here is what he wrote to me.

I am desperately seeking help restoring and repairing some of my dad’s smoking pipes. I have tried reaching out to the only two known pipe repair establishments I could find in the entire country but one is not currently taking repair orders and the other said she didn’t want to try to repair these pipes without having even seen them. Would you be willing to take on the repairs or can you recommend anyone? Thank you much!!!—Mario

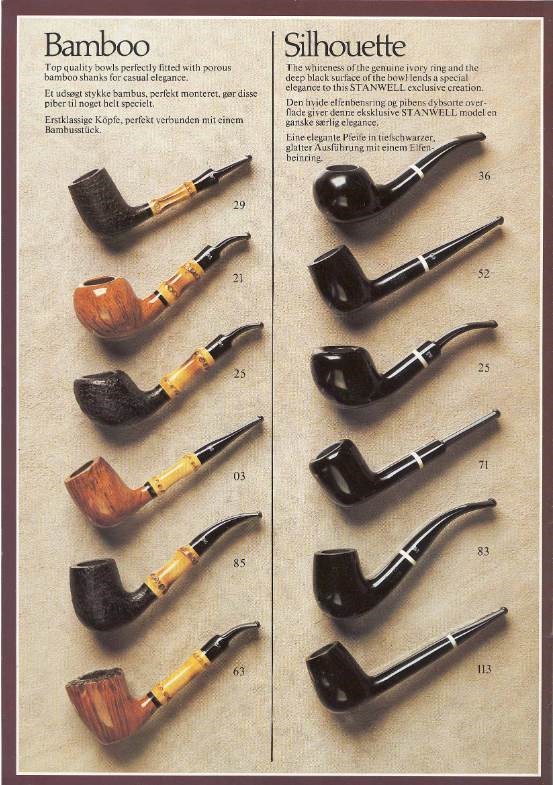

I wrote him back and asked him to send me photos of the pipes. He sent some single photos of the meerschaum bowl and stem, several of the leather clad Canadian and the photo of the rack and six pipes shown below. I looked through the photos and this is what I saw. There were two leather clad pipes a Canadian and a Pot. Both of them were cracked on the shanks and had been self-repaired with wire to hold the cracked shank together. The leather cladding was torn and the stitching was rotten and broken around the bowl. To me they were both unrepairable. There was a lovely older Meerschaum with a horn stem that needed a good cleaning and repairs to the horn stem. There were two Knute Freehand pipes with original stems that were dirty but fixable. The plateau on the smooth one had a large chunk of briar missing. There was a Dublin with a replacement stem that had been chewed through the topside. Finally, there was a billiard that had been restemmed with a fancy GBD saddle stem on it. They were a messy lot but I told him to send them on to me. They arrived yesterday and the condition of the pipes in the photos was confirmed. They were a mess and needed much work. I have included Mario’s group photo below to show the lot. This morning I decided to start working on the Billiard first. It was the one on the far right on top of the rack in the photo above. It was a billiard – not a GBD and the stem did not fit in the shank correctly and was a fancy saddle stem that had a huge bite through on the topside of it. The bowl had a thick cake on the walls and a heavy lava coat on the rim top. It was internally a mess. The finish was dirty and had a sticky coat on the right side of the bowl. There was a large fill on left side of the bowl near the top that had fallen out. There was a large crack in the shank on the right side that extended almost ¾ of an inch up the shank. The pipe was stamped on the left side of the shank and read Lou’s Tobacco Row. There was no other stamping on the shank sides. The stem was the wrong one. The diameter was less than the shank. The tenon was a bit large and when it had been used the shank had cracked. It would need to be banded and a new stem fit to the shank. I took photos of the pipe when I unpacked it to examine it. I have included those below.

This morning I decided to start working on the Billiard first. It was the one on the far right on top of the rack in the photo above. It was a billiard – not a GBD and the stem did not fit in the shank correctly and was a fancy saddle stem that had a huge bite through on the topside of it. The bowl had a thick cake on the walls and a heavy lava coat on the rim top. It was internally a mess. The finish was dirty and had a sticky coat on the right side of the bowl. There was a large fill on left side of the bowl near the top that had fallen out. There was a large crack in the shank on the right side that extended almost ¾ of an inch up the shank. The pipe was stamped on the left side of the shank and read Lou’s Tobacco Row. There was no other stamping on the shank sides. The stem was the wrong one. The diameter was less than the shank. The tenon was a bit large and when it had been used the shank had cracked. It would need to be banded and a new stem fit to the shank. I took photos of the pipe when I unpacked it to examine it. I have included those below.

I took a photo of the bowl and rim top to give you and idea of what I see. You can see the thick cake in the bowl and the thick lava overflow on the rim top and inner edges of the bowl. I also included one photo of the stem. You can see that the stem is not correct. It does not fit the shank and it is going to need to be replaced.

I took a photo of the bowl and rim top to give you and idea of what I see. You can see the thick cake in the bowl and the thick lava overflow on the rim top and inner edges of the bowl. I also included one photo of the stem. You can see that the stem is not correct. It does not fit the shank and it is going to need to be replaced. I took a photo of the stamping on the left side of the shank. It is clear and readable as noted above. I took a photo of the bowl with the incorrect stem removed to give a sense of the proportion and appearance of the pipe without the stem. You can see the damage on the stem top so it is no question that it needs to be removed.

I took a photo of the stamping on the left side of the shank. It is clear and readable as noted above. I took a photo of the bowl with the incorrect stem removed to give a sense of the proportion and appearance of the pipe without the stem. You can see the damage on the stem top so it is no question that it needs to be removed. I could not find any information on Lou’s Tobacco Row either as a pipe or a pipe shop. I googled and a Lou’s Tobacco Bar in Milwaukee, Wisconsin, USA but nothing with the stamp on this pipe. It remains a bit of a mystery to me.

I could not find any information on Lou’s Tobacco Row either as a pipe or a pipe shop. I googled and a Lou’s Tobacco Bar in Milwaukee, Wisconsin, USA but nothing with the stamp on this pipe. It remains a bit of a mystery to me.

I decided to addressed the cracks on the right underside of the shank first. I took a photo of the cracks on the underside of the shank. There seems to be several cracks in the briar. The crack extended a depth of over ¾ inches on the shank. I went through my bands to find one that had the depth to pull together the cracks up the depth of the shank. I found a nice Sterling Silver Band that was the right depth to pull together the damage on the shank. It was a snug fit. I heated it with a lighter to soften the silver and pressed it on to the shank end to bind the breaks together.

I reamed the bowl with a PipNet Pipe Reamer to take the cake back to bare briar. I cleaned up the cake with a Savinelli Fitsall Pipe Knife and removed the remaining debris. I sanded the bowl walls smooth with a piece of 220 grit sandpaper wrapped around a piece of dowel. I scraped the lava coat off the rim top with the Savinelli Pipe Knife and removed all of it.

I reamed the bowl with a PipNet Pipe Reamer to take the cake back to bare briar. I cleaned up the cake with a Savinelli Fitsall Pipe Knife and removed the remaining debris. I sanded the bowl walls smooth with a piece of 220 grit sandpaper wrapped around a piece of dowel. I scraped the lava coat off the rim top with the Savinelli Pipe Knife and removed all of it.

I cleaned out the internals of the bowl and shank with pipe cleaners, cotton swabs, shank brushes and 99% isopropyl alcohol. It was very clean and it looked and smelled far better. I really liked the look of the shank band on the shank end.

I cleaned out the internals of the bowl and shank with pipe cleaners, cotton swabs, shank brushes and 99% isopropyl alcohol. It was very clean and it looked and smelled far better. I really liked the look of the shank band on the shank end. I scrubbed the externals of the bowl and shank with undiluted Murphy’s Oil Soap and a tooth brush. I worked over the bowl, shank and rim top with the soap and then rinsed it off warm water. The bowl looked extremely good. There was one spot near the top left side of the bowl that would need to have a fill repaired. The briar looked very good with the sterling silver band on the shank.

I scrubbed the externals of the bowl and shank with undiluted Murphy’s Oil Soap and a tooth brush. I worked over the bowl, shank and rim top with the soap and then rinsed it off warm water. The bowl looked extremely good. There was one spot near the top left side of the bowl that would need to have a fill repaired. The briar looked very good with the sterling silver band on the shank.

I cleaned up the inner edge of the bowl and the rim top with a folded piece of 220 grit sandpaper. It took a bit of work but I was able to remove the darkening on the edge, the nicks and damage and also some of the marks on the rim top.

I cleaned up the inner edge of the bowl and the rim top with a folded piece of 220 grit sandpaper. It took a bit of work but I was able to remove the darkening on the edge, the nicks and damage and also some of the marks on the rim top. I applied some clear CA glue in the damaged fill on the left side of the bowl. I worked it into the space on the briar with a tooth pick. I pressed some briar dust into the fresh glue repair. Once it cured I sanded it smooth with a folded piece of 220 grit sandpaper.

I applied some clear CA glue in the damaged fill on the left side of the bowl. I worked it into the space on the briar with a tooth pick. I pressed some briar dust into the fresh glue repair. Once it cured I sanded it smooth with a folded piece of 220 grit sandpaper.

I used 320-3500 grit sanding pads to smooth out the scratches and nicks in the surface of the briar. There were many small scratches and nicks in the briar. I wiped the bowl down after each sanding pad with a damp cloth to remove the sanding dust and debris. It really began to llok very good. The grain is quite lovely.

I used 320-3500 grit sanding pads to smooth out the scratches and nicks in the surface of the briar. There were many small scratches and nicks in the briar. I wiped the bowl down after each sanding pad with a damp cloth to remove the sanding dust and debris. It really began to llok very good. The grain is quite lovely.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiped it down the bowl after each sanding pad.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiped it down the bowl after each sanding pad.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out.

I went through my can of stems and found one that was the right taper for the pipe bowl I was working on. It had the right look and would need a little adjustment to the bottom half of the stem to make the fit against band end equal all the way around the shank end.

I went through my can of stems and found one that was the right taper for the pipe bowl I was working on. It had the right look and would need a little adjustment to the bottom half of the stem to make the fit against band end equal all the way around the shank end. I cleaned out the internals of the stem with alcohol and pipe cleaners. It was surprisingly clean so it was ready to work on it to make a proper fit.

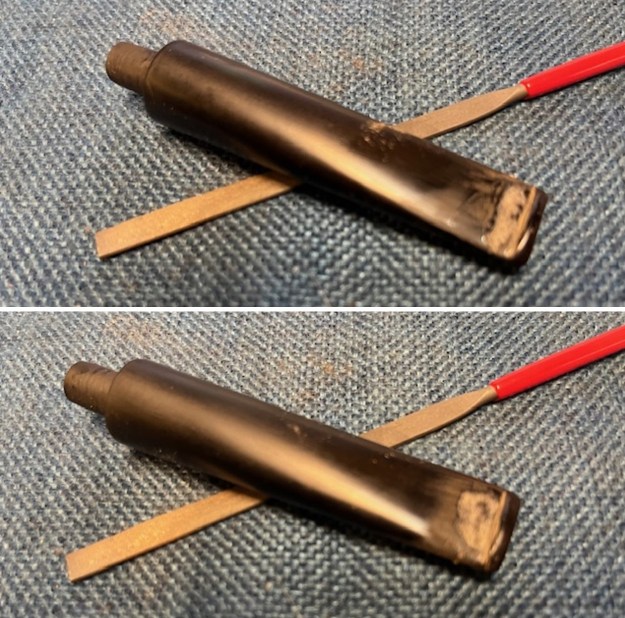

I cleaned out the internals of the stem with alcohol and pipe cleaners. It was surprisingly clean so it was ready to work on it to make a proper fit. I worked over the diameter of the stem at the band junction to reduce it to fit against the shank end. I used the Dremel and sanding drum to start the process and then finished the fit with 220 grit sandpaper to smooth out the sanding marks on the vulcanite. I also sanded over the tooth marks in the stem on both sides ahead of the button.

I worked over the diameter of the stem at the band junction to reduce it to fit against the shank end. I used the Dremel and sanding drum to start the process and then finished the fit with 220 grit sandpaper to smooth out the sanding marks on the vulcanite. I also sanded over the tooth marks in the stem on both sides ahead of the button.

There were some small tooth marks on each side of the stem that remained after my sanding. I filled them in with clear super glue and used a tooth pick to flatten them out (I forgot to take a photo of the stem at this point). Once the repairs cured I flattened them with a small file. I sanded them smooth with a folded piece of 220 grit sandpaper.

There were some small tooth marks on each side of the stem that remained after my sanding. I filled them in with clear super glue and used a tooth pick to flatten them out (I forgot to take a photo of the stem at this point). Once the repairs cured I flattened them with a small file. I sanded them smooth with a folded piece of 220 grit sandpaper.

I sanded the stem to smooth it out with 320-3500 grit sanding pads. I wiped the stem down after each pad with an Obsidian Oil cloth. It was beginning to look very good.

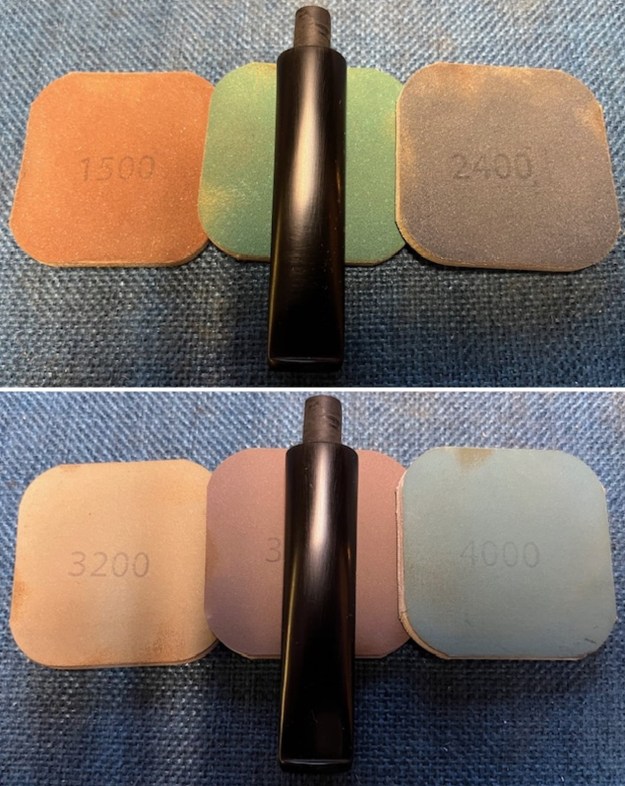

I sanded the stem to smooth it out with 320-3500 grit sanding pads. I wiped the stem down after each pad with an Obsidian Oil cloth. It was beginning to look very good. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with a damp cloth after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This first of Mario’s Dad’s pipes, a banded, restored and restemmed Lou’s Tobacco Row Billiard with a new vulcanite taper stem is a great looking pipe now that it has been restored. The beautiful finish really highlights the grain and the polished finish is stunning with the Sterling Silver Band. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Lou’s Tobacco Row Billiard is a large pipe, but it fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 52 grams /1.87 ounces. This is the first of six pipes that I am restemming and restoring for Mario from his Dad’s collection. I look forward to hearing what he thinks of this newly banded and stemmed pipe. Thanks for reading this blog and my reflections on the pipe while I worked on it.

This first of Mario’s Dad’s pipes, a banded, restored and restemmed Lou’s Tobacco Row Billiard with a new vulcanite taper stem is a great looking pipe now that it has been restored. The beautiful finish really highlights the grain and the polished finish is stunning with the Sterling Silver Band. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Lou’s Tobacco Row Billiard is a large pipe, but it fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 6 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 52 grams /1.87 ounces. This is the first of six pipes that I am restemming and restoring for Mario from his Dad’s collection. I look forward to hearing what he thinks of this newly banded and stemmed pipe. Thanks for reading this blog and my reflections on the pipe while I worked on it.