Blog by Steve Laug

The next pipe on the work table is long and classic looking smooth finish straight grain Billiard. It is faintly stamped on the left side of the shank and clearly reads GBD in an oval [over] XTRA [over] Straight Grain. On the right side of the shank it is faintly stamped London England [over] an impossible to read shape number. It came from a lot we purchased on 03/21/2024 from an estate in Oregon City, Oregon, USA. It is a Billiard pipe with some great grain and having a replacement vulcanite taper stem. There is a Sterling Silver Band on the shank end showing a shank repair that was glued and banded. The bowl has a thick cake and some lava overflow in the finish on the rim top and inner edge. The rim top and inner and outer edge showed damage from being knocked against a hard surface. The finish looked quite good in terms of wear and tear but there was dirt and hand oils in the finish. Under the grime the finish looked very good and highlights some beautiful grain. The twin bore replacement stem was lightly oxidized and there was a Softee Bit on the stem end. Underneath the rubber Softee Bit there were some light tooth marks. Jeff took photos of the pipe before he started his cleanup.

Jeff took photos of the bowl and rim top to show the cake in the bowl and the condition of both. It was heavily caked with a light lava overflow on the rim top. The rim top and the outer edge show damage on the left front from being knocked against a hard surface. He took photos of the top and underside of the stem with the Softee Bit in place and then removed showing the light oxidation and tooth marks on the stem surface and button. The stem is not the original it is a twin bore bite proof stem that is a replacement.

Jeff took photos of the bowl and rim top to show the cake in the bowl and the condition of both. It was heavily caked with a light lava overflow on the rim top. The rim top and the outer edge show damage on the left front from being knocked against a hard surface. He took photos of the top and underside of the stem with the Softee Bit in place and then removed showing the light oxidation and tooth marks on the stem surface and button. The stem is not the original it is a twin bore bite proof stem that is a replacement.

Jeff took photos of the heel and the sides of the bowl and shank to show the grain on the pipe. It is a beauty.

Jeff took photos of the heel and the sides of the bowl and shank to show the grain on the pipe. It is a beauty.

He took photos of the side of the shank to show the faint stamping on the left side. His photos also show the repaired crack on the left side of the shank. The silver band is stamped Sterling Silver and is readable.

He took photos of the side of the shank to show the faint stamping on the left side. His photos also show the repaired crack on the left side of the shank. The silver band is stamped Sterling Silver and is readable.

I turned to PipePhil’s site (http://www.pipephil.eu/logos/en/logo-gbd.html) to see what I could find. The site had a photo and information on a GBD Xtra but not a lot of background on it. The photo shown was from the 1930s but it is also noted as a New Era Pipe. There was nothing on a pipe stamped as GBD Xtra Straight Grain.

I turned to PipePhil’s site (http://www.pipephil.eu/logos/en/logo-gbd.html) to see what I could find. The site had a photo and information on a GBD Xtra but not a lot of background on it. The photo shown was from the 1930s but it is also noted as a New Era Pipe. There was nothing on a pipe stamped as GBD Xtra Straight Grain.

I then turned to Pipedia (https://pipedia.org/wiki/GBD) to see if there was info the brand. It is a great read in terms of history but there was nothing giving details on a GBD Xtra Straight Grain.

The claims after the 1st World War demanded further distinctions. First of all was the London Made, which became the Standard London Made, followed by the New Era– in 1931 the top model asking 12½ Shilling. The Pedigree, although sketched around 1926, was not produced until the later 1930s. The New Standard was introduced in order to give the popular Standard of the 20s a higher rank in value. The Prehistoric, a deeply sandblasted black pipe, that still carried the small GBD Xtra stamp, was entirely new and unusual.

From that small note I knew that I was working on a post WW1 Pipe that carried the GBD Xtra stamp.

I then followed a link at the end of the article to another article on Pipedia about model information (https://pipedia.org/wiki/GBD_Model_Information). There I found a very brief listing on the Xtra stamping and the Straight Grain stamping. However there was nothing with the two combined.

Xtra — Factory unknown: Reddish smooth -PR: Introduced in 1930s?

Straight Grain — France and made in England too

https://pipesmagazine.com/forums/threads/old-gbd-xtra-ive-hit-a-research-wall.64992/

A brief summary of what I think I know scavenged from Pipedia/forums etc. Back around the late 20s, GDB didn’t grade their briar, so they created two designations – the Xtra and the Special to denote pipes that have had addition features/finishes etc. These weren’t product/model lines, but more of a grade system that differentiated it from the standard GBD (which had just the ‘GBD’ stamp). By 1937, the Xtra/Special designations were dropped and the more tradition model lines were introduced (Pedigree/New Era etc). However, there were a couple of exception: some Prehistorics were also marked ‘Xtra’, and a 1950s catalogue I’ve seen also seems to carry the Xtra line (although they do look quite different). I’ve been trying to determine if this is one of the 1930s Xtras, with little luck.

That paragraph gave me a bit of a hint that the Xtra designation was used on pipes that had additional features not identifying product lines but more of a grade system. It also tells me that the stamping ended by 1937. There are also examples of it showing up in the 1950s. Below the next part is a quote from Jacques Cole and he notes that the XTRAs were the cream, being mostly with straight grains!

Further on in the thread on the above pipe I found this response by snagstangl that reads as follows:

I was re reading a Jacques Cole article concerning GBDs titled “Story of a Pipe Brand” it had this to say about this topic:

“We have seen that early Briar GBDs were made in only one, later two qualities and the need to mark the difference did not arise. There were few finishes but towards the end of the 19th century demand was changing, for instance the UK had a “penchant” for the darker finishes. Qualities were therefore sub-divided and we see the introduction of the GBD XTRA (note the spelling). The GBD Speciales were as the name implied, special models, finishes and fittings. GBD XTRAs were the cream, being mostly straight grains. The “ordinary* quality was simply

stamped GBD. Demand after the First World War called for further identification starting with GBD ‘London Made* which became ‘Standard London Made*, followed by GBD “New Era’, top of the range in 1931 at 12/6d! GBD ‘Pedigree’, although first thought of around 1926, was well established in the late 1930s. GBD “New Standard’ was created to give a boost to the “Standards’ of the 1920s and a newly introduced sandblast was called GBD ‘Prehistoric’, still bearing a small GBD ‘Xtra* stamp. French made GBDs followed more or less the same ideas, still however using ‘Xtra’ and ‘Speeiale’ while in the late ’20s a metal system GBD was introduced under the name GBD ‘Extra Dry*. The 1920s also saw an important development with the introduction of the metal GBD inlay on mouthpieces which gave the pipes that extra ‘touch of class’. This inlay has been used on GBDs for nearly 60 years.”

That was followed by a response from osiris01:

I started with either this text or one using it as source and it does explain well the reason for creating, first the Xtras and Speciales, and later, the other graded lines like New Era, Pedigree etc. The problem is that the Xtra and Speciale were discontinued in 1937/8 (Pipedia et al) because the new lines provided a more refined grading system. And yet, the Xtra was listed in the catalogs until 1950.

My guess is that the French factory continued with the Xtra, for a reason unknown to me. The only evidence I have of this is a badly translated sentence from Pipedia that describes the process of creating additional lines. It reads “The French GBDs more or less followed the same developments, although Xtra and Speciale very longly used there.” What ‘Longly used there’ means I don’t know, but somewhere was still making them, and if you translate ‘longly’ as ‘longer’, it does imply that they continued making them for a longer period. It’s a far from perfect explanation but, as I said, they were still being made somewhere and it does imply that the French factory were responsible. However, they were different to the Xtras made in the 20s/30s since the later ones had a chamfered rim, different stems etc.

However, reading you text again, I wonder if the it is hinting at a COM. “Demand after the First World War called for further identification starting with GBD ‘London Made* which became ‘Standard London Made*,”. It doesn’t say that a COM was not used before then (that would be too easy), but you wouldn’t stamp a pipe “Xtra, London Made, London Made” or similar.

I just don’t have enough evidence, reference points, old models to compare against etc. Even describing it as an educated guess is still stretching it a bit. The best guess, perhaps.

However, what I do know is that the 1930s Xtras were fitted with a specific stem with an unusual button called the ‘curved wafer tip of comfort’ (just rolls off the tongue). The following images shows the detail from a 1938 catalogue and the button on my pipe, and to my eye, they are the same. Not in any way conclusive, but it’s the best I’ve been able to come up with.

Now I knew that I was dealing with a French made GBD created in the 1950s. It did not have the original stem so the information on the stem did not help.

Jeff reamed it with a PipNet pipe reamer and cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He scrubbed out the internals of the shank and stem with alcohol, pipe cleaners and cotton swabs until the pipe was clean. He scrubbed the exterior of the bowl with Murphy’s Oil Soap and a tooth brush to remove the grime and grit on the briar and the lava on the rim top. The finish on the bowl looked really good when I got it. The rim top and edges looked very good. He soaked the twin bore stem in Briarville’s Pipe Stem Deoxidizer bath to remove the oxidation. The stem looked better and the deep tooth marks and chatter on the surface were also visible. When the pipe arrived here in Vancouver for the second stop of its restoration tour it looked much better than when he found it. I took photos of the pipe before I started my work on it.

I took photos of the condition of the rim top and stem before I started working. The rim top looks very good and the bowl is spotless. The stem is much better but still shows some tooth chatter and marks on both sides near the button.

I took photos of the condition of the rim top and stem before I started working. The rim top looks very good and the bowl is spotless. The stem is much better but still shows some tooth chatter and marks on both sides near the button.  I took photos of the stamping on the sides of the shank. The stamping was faint but still readable with a lens and light. It reads as noted above. I took the bowl and stem apart and took a photo of the pipe to show the look of the pipe.

I took photos of the stamping on the sides of the shank. The stamping was faint but still readable with a lens and light. It reads as noted above. I took the bowl and stem apart and took a photo of the pipe to show the look of the pipe.

Now it was time to work on the rim top and bowl edge damage. I cleaned up the inner edge with a folded piece of 220 grit sandpaper to smooth out the burn damage and cuts from reaming with a knife. I used a piece of 220 grit sandpaper and a wooden sphere to work on the edges to give it a slight bevel. I used a topping board to smooth out the damage on the top. It was looking better at this point.

Now it was time to work on the rim top and bowl edge damage. I cleaned up the inner edge with a folded piece of 220 grit sandpaper to smooth out the burn damage and cuts from reaming with a knife. I used a piece of 220 grit sandpaper and a wooden sphere to work on the edges to give it a slight bevel. I used a topping board to smooth out the damage on the top. It was looking better at this point.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the sanding dust.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the sanding dust.

I worked some Before & After Restoration Balm into the finish of the bowl, rim top and shank with my fingertips to clean, enliven and protect it. I find that the balm really makes the briar come alive again. The contrasts in the layers of stain really made the grain stand out. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The bowl really looks good at this point.

I worked some Before & After Restoration Balm into the finish of the bowl, rim top and shank with my fingertips to clean, enliven and protect it. I find that the balm really makes the briar come alive again. The contrasts in the layers of stain really made the grain stand out. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The bowl really looks good at this point.

I set aside the bowl and turned my attention to the stem. I “painted” the tooth marks on the surface of the stem and was able to lift all of them. Those that remained I removed by sanding them out with 220 sandpaper to blend them into the surface.

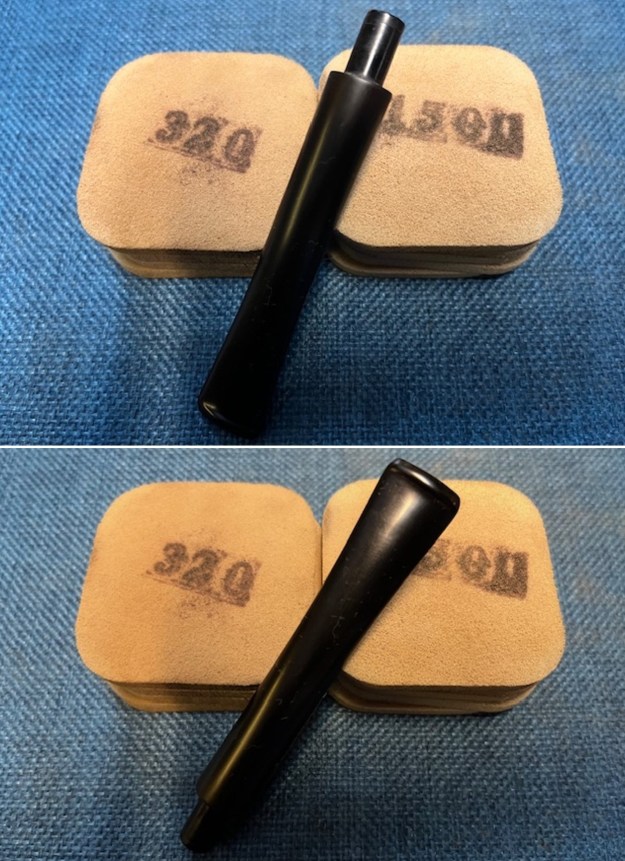

I set aside the bowl and turned my attention to the stem. I “painted” the tooth marks on the surface of the stem and was able to lift all of them. Those that remained I removed by sanding them out with 220 sandpaper to blend them into the surface. I sanded the stem with 320-3500 grit sanding pads and wiped the stem down after each pad with an Obsidian Oil saturated cloth to remove the grime and protect the stem.

I sanded the stem with 320-3500 grit sanding pads and wiped the stem down after each pad with an Obsidian Oil saturated cloth to remove the grime and protect the stem. I polished the stem with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I polished it further with Before & After Pipe Stem Polish – both fine and extra fine.

I polished the stem with micromesh sanding pads – wet sanding it with 1500-12000 grit pads. I polished it further with Before & After Pipe Stem Polish – both fine and extra fine.

Once again, I am the part of the restoration that I always look forward to – the moment when all the pieces are put back together. I put the pipe back together and buffed the bowl and the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with the smooth finish and the black vulcanite stem. This richly stained GBD Xtra Straight Grain Billiard with a sterling silver repair band and a twin bore vulcanite stem is light weight and ready for you to load up a tobacco of preference and enjoy. Have a look at it in the photos below. The dimensions are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 39 grams/1.38 ounces. This is one that will go on the British Pipemakers Section of the rebornpipes online store shortly. Let me know if you are interested in adding it to your rack. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.

Once again, I am the part of the restoration that I always look forward to – the moment when all the pieces are put back together. I put the pipe back together and buffed the bowl and the stem with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with the smooth finish and the black vulcanite stem. This richly stained GBD Xtra Straight Grain Billiard with a sterling silver repair band and a twin bore vulcanite stem is light weight and ready for you to load up a tobacco of preference and enjoy. Have a look at it in the photos below. The dimensions are Length: 6 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 39 grams/1.38 ounces. This is one that will go on the British Pipemakers Section of the rebornpipes online store shortly. Let me know if you are interested in adding it to your rack. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next generation.